- What is an AC motor?

- Working Principle of an AC motor

- Construction of an AC motor

- Speed Control of an AC motor

- How should we select an AC motor?

- AC motor types

- Synchronous Motor

- Induction Motor

- Single Phase Induction Motor

- Three Phase Induction Motor

- Advantages of an AC motor

- Disadvantages of an AC motor

- Applications of an AC motor

- Some Useful Questions

An electrical device that converts electrical current into mechanical current is referred to as an electric motor. Electric motors perform an important part in daily life. Electric motors are incredibly effective machines, the level of which is mostly determined by the size of the motor and the mode in which it is operating. Unlike other electrical devices, electric motors do not require fuel or engine oil for maintenance. The two primary types of electric motors are

- AC motors and

- DC motors.

Because AC motors are typically more expensive than DC motors, they are used less frequently in daily life.

AC motors are primarily chosen because they function inconspicuously and have a high degree of flexibility in their working structure.

What is an AC motor?

An alternating current motor is one that uses electromagnetic induction to convert alternating current into a mechanical power. An alternating current drives this motor.

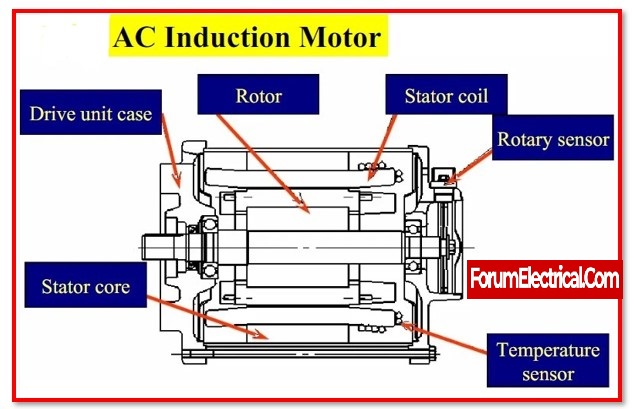

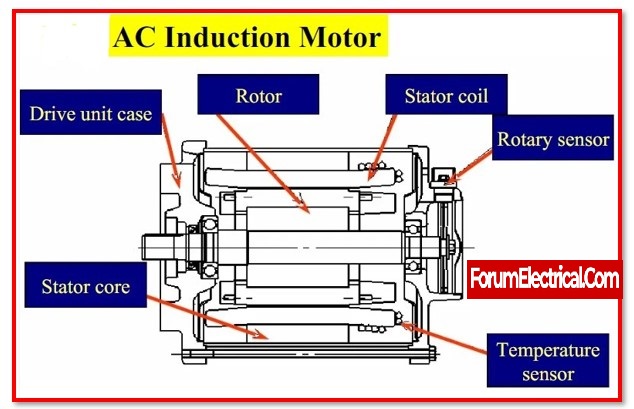

The stator and rotor are the two most significant components of an alternating current motor.

The stator is the motor’s stationary component, & the rotor is the motor’s rotating component.

The alternating current motor can be single phase (or) three phase.

These motors are quite useful to generate constant torque at the rated speed. These motors are easy to use and can be modified at a low cost.

Working Principle of an AC motor

The basic operation of an AC motor is based mostly on magnetism. The simplest AC motor consists of a wire coil and two permanent magnets located near a shaft. When an alternating current is passed through the wire coil, it transforms into an electromagnet that generates a magnetic field. The stator and rotor are the two most important components of this motor. This stator is made up of a number of different components, including a solid metal axle, a wire loop, freely moving metal components that conduct electric power, a coil, and a squirrel cage.

They can transmit power to the external coils in the stator of an AC motor to build up a stationary component like the stator. The wire coils can be activated in pairs and in series to create a magnetic field that turns the ac motor’s exterior.

Because the rotor is balanced inside the magnetic field, which changes constantly due to rotation, the magnetic field may generate an electric current inside the rotor, according to the electromagnetism law.

If the conductor is a wire or a ring, current will flow in a loop around it; while the conductor is the solid metal piece, eddy current will flow around it. The induced current can generate a magnetic field, and the rotational magnetic field will rotate as well, according to another electromagnetism equation. When the magnets interact one another, the coil of wires and shaft starts to turn the motor.

Construction of an AC motor

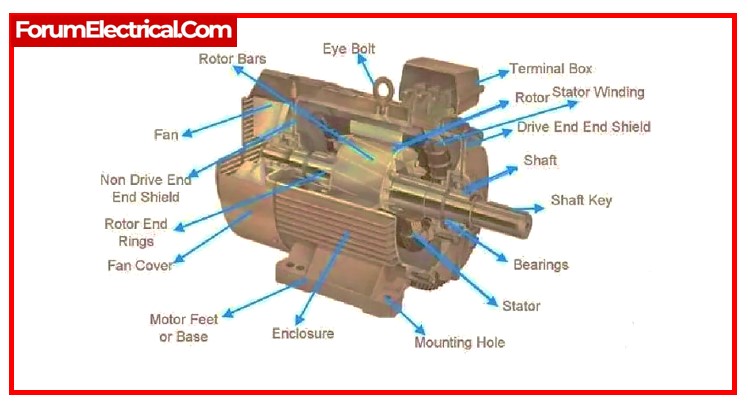

The stator, a stationary component, and the rotor, a revolving component, are the two fundamental components of an AC motor. In addition to these, there are some more components, which are covered below.

1). Stator

2). Stator Core

3). Stator Windings

4). Rotor

5). Shaft

6). Bearings

7). Enclosure

1). Stator

The stator, an inactive component of the ac motor, serves primarily to transfer a rotational magnetic field that interacts with the rotor.

2). Stator Core

In order to reduce energy loss, the stator core of the motor is constructed with laminations (or) thin metal sheets.

3). Stator Windings

The motor’s stator windings will load collectively to create a hollow cylinder. The insulated wire slots in the stator core coils are regulated and protected. The stator windings can be connected to a power supply once the assembly of the ac motor is complete. Once the current source is delivered, each coil group with steel core will transform into an electromagnet.

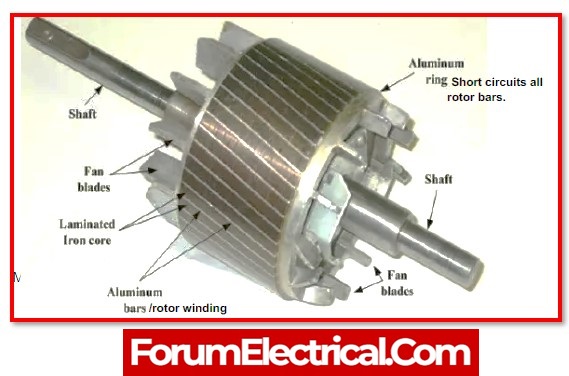

4). Rotor

The rotor, which rotates within the motor, is a crucial component attached to the shaft. The squirrel cage rotor is the most prevalent form of rotor utilized in an AC motor. It is manufactured into a cylindrical shape by stacking thin steel laminations.

5). Shaft

By applying pressure to a steel shaft that expands the outside of the motor housing, the rotor assembly can be created. This connection to an external system allows the rotational power to be disseminated.

6). Bearings

The motor’s shaft has bearings installed on it to support the rotor and permit rotation. Some motor types use a fan by mounting it on the rotor shaft to cool the motor once its shaft starts rotating.

Bearings are used in ac motors to keep the shaft in place. In this case, bearings will lessen the friction of shaft that is linked to the casing in order to increase motor efficiency.

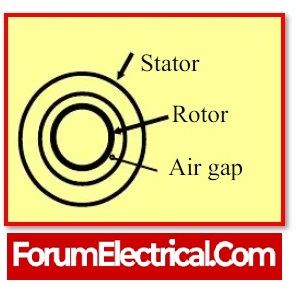

7). Enclosure

Two end brackets and a yoke (or) frame are part of the motor’s enclosure. The rotor is positioned inside the stator via a small air gap that isolates it from the stator, which is housed inside the frame. The rotor and stator are not directly physically connected.

The motor’s enclosure protects the internal components from water and the environment. This component consists of a frame and two end brackets.

Speed Control of an AC motor

The majority of industrial settings where AC motors are used are those where heavy-duty machines need to be controlled. AC motors must be managed in power plants where timeliness and accuracy are essential to the operation. Therefore, ac motor frequency and speed can be controlled using a variety of methods.

There are various ways to change the speed of an AC motor, including

1). Changing the number of poles in incredibly small steps,

2). Motor’s slip, and

3). Frequency of the AC signal.

1). Changing the number of poles

Among those mentioned methods, changing the poles is not frequently employed because it is ineffective for frequent control.

2). Motor’s slip

If the AC motor is made primarily for high slip, an additional approach like changing the motor’s rotor slip is frequently used. This motor should therefore be comparable to the electric load using this method. Therefore, the load speed will change as the power is altered. This load must also have significant inertial components.

3). Frequency of the AC signal

Altering the motor’s frequency is the method most usually used to adjust an AC motor’s speed. Using this method, AC motor drives with variable speed—also referred to as

- VFD (variable frequency drives),

- ASD (adjustable speed drives), or AC inverters—are used to alter the motor speed.

To change the AC frequency, a six-step inverter, PWM (Pulse Width Modulation), (or) vector flux is employed.

A variable voltage inverter, often known as a six-step inverter, converts power primarily from AC to DC before switching to reproduce a sine wave.

The PWM method swiftly changes DC voltage to equivalent “area under the curve.”

It can run a power plant in which AC motors are used to power fans, pumps, etc. by taking into consideration certain AC motor speed control techniques.

To maintain a process moving smoothly, many applications require accuracy. Installing reliable AC drives, which are primarily made to properly control motor speed, is a simple procedure.

These techniques come with a variety of control options, making it easy to find speed controls that satisfy the application’s needs.

The ability to seamlessly manage machine operation, control acceleration, change production rates, save energy, and more are the major advantages of the ac motor speed controllers.

How should we select an AC motor?

When selecting an AC motor, a few things need to be taken into consideration.

- Must be aware of the power requirements; the AC motor shouldn’t operate across their load because it could be damaged.

- It is important to choose the motor on the basis of the starting torque.

- Should take starting torque into consideration.

- Efficiency and pull-out torque are important considerations.

AC motor types

are the two types of AC motors.

Synchronous Motor

A synchronous motor’s primary function is to convert AC electrical energy into a mechanical energy. This type of motor operates simply at synchronous speed.

According to the synchronous motor’s operating theory, a rotating field can be created after the motor gets powered. As a result, this field tries to draw the rotor through it but is unable to do so because the rotor is not moving. As a result, no starting torque is capable of being generated. Therefore, this motor cannot start on its own.

Induction Motor

Asynchronous motor is another term for the induction motor. This motor’s purpose is to convert AC power through the electromagnetic induction into mechanical power. This type of motor can be divided into two categories:

- Single-phase induction motor and

- Three-phase induction motor

The armature winding of an induction motor functions as both the armature winding and the field winding. Once the stator windings are connected to an AC source, flux can be produced inside the air gap. Here, the flux will rotate at synchronous speed, which is a predetermined speed. Therefore, the rotational flux inside the stator and rotor windings can induce voltages.

If the rotor’s circuit is closed, current flows through its winding and reacts with the rotary flux to produce a torque. The rotor rotates at a speed that is very close to synchronous speed while the system is steady.

Single Phase Induction Motor

In general, a single-phase induction motor is constructed similarly to a three-phase motor. While short-circuited conductors are positioned within the rotating part like the rotor, AC windings can be mounted on a stationary portion like the stator. The single-phase supply to the stator is the primary distinction between these two.

If analyse the motor diagram, the stator’s winding receives an ac supply, which causes a pulsing flux density to be produced that connects the rotor circuits. The induced voltage in the rotor circuits will result in a current supply, creating a flux density that to resist change in the stator flux coupled to the circuit.

The flux densities of the motor’s rotational and stationary components will both move in the y-direction. This simple qualitative analysis identifies a problem: the single phase (1Ø)supply will produce pulsing fields rather than rotating fields because pulsating fields do not produce torque.

Three Phase Induction Motor

Three phase induction motors are widely utilized in industrial applications to provide mechanical energy. The majority of motors used in factories are three-phase induction motors. This motor is therefore the most important one when compared to other motors.

When compared to a single-phase induction motor, this type of ac motor operates on a three-phase supply wherever a single-phase supply is necessary to activate it. The three phase (3Ø)supply will produce an electromagnetic field inside the stator winding, which causes the torque to be generated inside the motor’s rotor winding along with the magnetic field.

Advantages of an AC motor

- Design is basic and easy.

- Power factor is favourable.

- Inexpensive

- This motor can be directly linked to an AC source.

- Lower maintenance

Disadvantages of an AC motor

- This motor’s starting torque is relatively low.

- It won’t work at slow speeds.

- Poor control of positioning

- Speed across the frequency supply is limited.

Applications of an AC motor

- They are suitable for projects where consistent movement and steady speed are not required.

- They are inappropriate for uses that need very low speeds.

- For applications requiring high performance and torque output, these motors are a great option.

- Power tools, fans, clocks, disk drives, blowers, compressors, pumps, conveyors, turntables for audio, home appliances, washing machines, and industrial settings all employ these motors.

Some Useful Questions

1). What is the advantage of an AC motor over a DC motor?

Brushless alternating current motors generate high torque. A controller can control the power & speed of an AC motor. AC motors do not ignite since they do not require a brush or commutator.

2). What is the purpose of the shaft and bearing?

In an alternating current motor, bearings are used to position the shaft. Bearings help to reduce friction on the shaft that is aligned with the casing, allowing the motor to run more efficiently.

3). What is the primary difference between single-phase and three-phase motors?

The single phase (1Ø) induction motor requires only one phase of power to operate. The three-phase (3Ø), on the other end, does not require any additional equipment to start