- What is a (DOL) Direct Online Starter?

- Direct online starter (DOL Starter) components:

- DOL Starter Circuit Diagram:

- Working Principle of DOL Starter:

- Overload Protection:

- Under-Voltage Protection:

- Characteristics of DOL Starter:

- Why DOL starter used in an Induction motor?

- Why does an induction motor require 6 times the starting current with a DOL starter?

- Why is the power factor of an induction motor with a DOL starting so poor?

- Advantages of DOL Starter:

- Disadvantages of DOL Starter:

- Applications of DOL Starter:

The induction motor consumes a large quantity of current. This starting current can harm the motor windings.

To avoid any harm, it is required to employ various methods to reduce the starting current when using a motor starter.

These techniques are dependent on the motor ratings and the load linked to the motor. Aside from that, the motor starter helps to protect the motor from overloading and overcurrent.

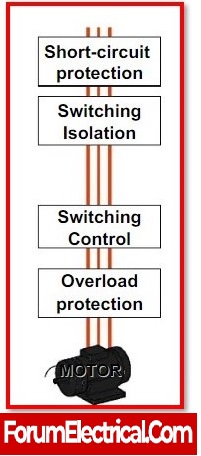

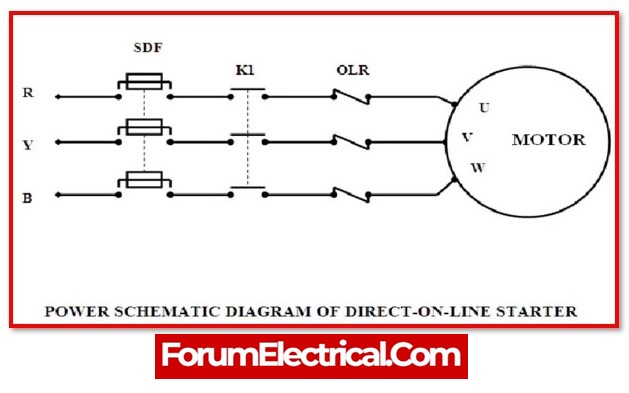

The Direct Online (DOL) starter uses a full voltage or across the line starting technique in which the motor is directly linked to full voltage via an MCB or circuit breaker and relays for overload safety.

This is why such a starter is utilised with induction motors rated less than 5 horsepower.

What is a (DOL) Direct Online Starter?

DOL Starter (Direct Online Starter) is also known as “across the line starter”. A DOL starter is a device that includes a main contactor, protection devices, and an overload relay and is used to start motors.

It is used for low-power motors with ratings of less than 5 HP.

The motor stator windings are directly linked to the main supply in the direct online starter method of motor starting, where the DOL protects the motor circuit from high inrush current, which may harm the overall circuit as the initial current is significantly higher than the full rated current.

Direct online starter (DOL Starter) components:

1). The contactor:

A contactor is a high-current-rated heavy-duty relay used to power an electrical motor. Contactor current ratings range from 10 amps to several hundred amps.

The high current contactor is built of a silver-containing alloy. Arcing during contactor switching causes the contact to oxidise. Silver oxide, remains a good conductor.

Overload protection is included, as are the contractors for starting the motor. Unlike a circuit breaker, a contactor is not employed to terminate a short circuit current.

For high current appliances, contactor sizes range from small to large.

While switching, the contactor generates noise. When silent operation is required, a solid-state relay is employed.

A contactor is an electromechanical switch that functions on the coil’s energization and de-energization.

If power fails suddenly due to this contactor coil becoming de-energized, it opens the contactor terminal and disconnects the motor from the supply.

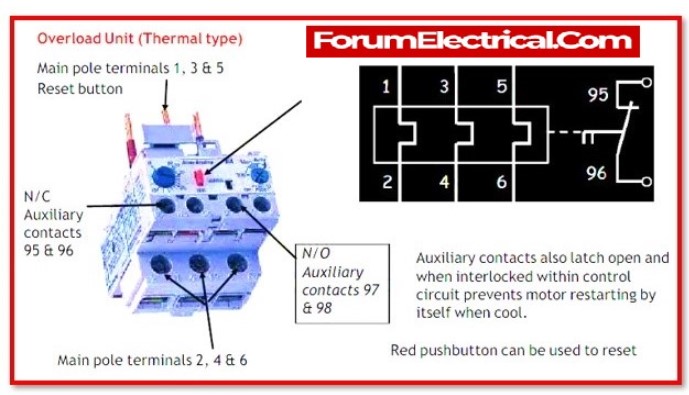

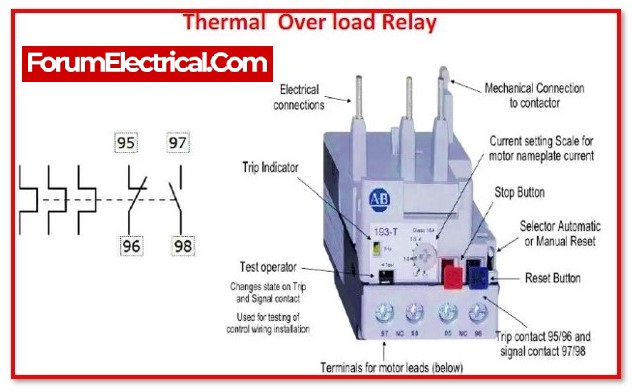

2). Overload relay (protection against overload):

Overload is the most common cause of motor winding failure. Motor overload causes heating of the motor winding, which weakens the winding insulation.

A little overload does not cause a motor to fail immediately, but it can reduce the estimated lifetime.

A thermal overload relay is built into a direct online starter circuit to prevent this from happening.

A bimetallic strip bends due to overheating produced by overcurrent in a thermal overload relay.

This will isolate the motor from the power source and avoid future motor winding damage as well as insulation failure.

3). Miniature circuit breakers (MCBs):

In the DOL circuit, an MCB is used to protect the motor from short circuit condition and to prevent damage to the motor winding.

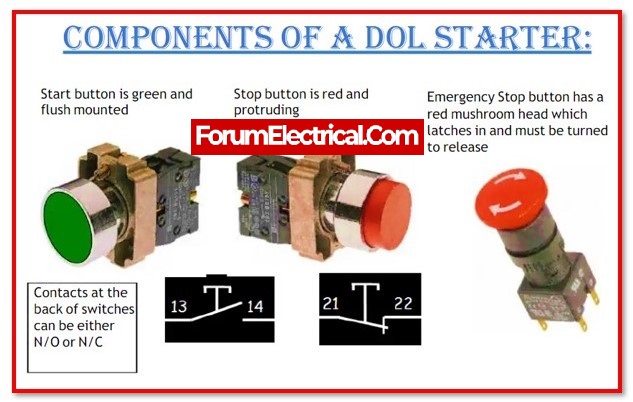

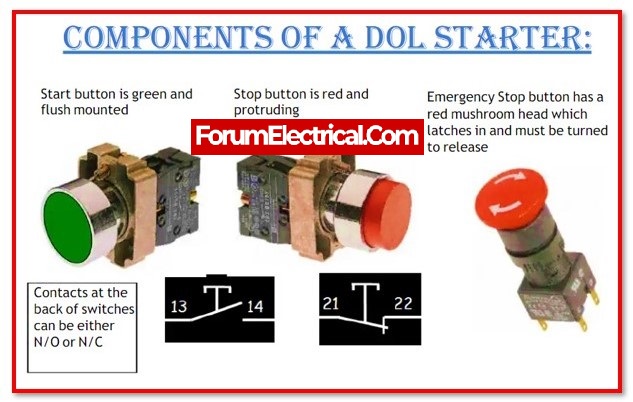

4). Push button:

The power supply is switched using an electromechanical contactor with 3 to 4 poles.

5) Push Start Button:

6) Push Stop Button:

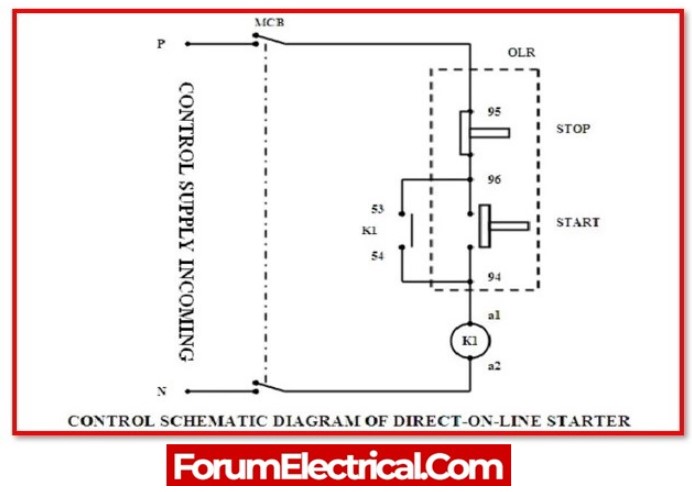

DOL Starter Circuit Diagram:

The motor is not harmed as a result of this direct connection. A DOL motor starter includes protection devices as well as condition monitoring in some applications.

There is a little difference between the way the wiring is accomplished for three phase and single phase. The following is the wiring for both a single phase and a three phase DOL starter:

1). Single Phase DOL Starter Wiring:

The following diagram illustrates the components that can be implemented in the construction of a single-phase DOL motor starter.

FOR ANSI STANDARDS CLICK HERE

In order to prevent the overload relay from tripping unnecessarily, it is essential to make use of all three of its poles.

Failing to do so will result in an imbalance caused by current flow in only two of the poles.

2). Three Phase DOL Starter Wiring:

The overload relay and fuse unit can be seen in the Direct Online Line Starter diagram as symbols OLR and K1 respectively.

Within a direct on-line motor starter, it is also possible to connect MCBs for the purpose of providing protection.

Working Principle of DOL Starter:

- The start push button is pressed to start the motor. Further to then, electromechanical operation and the latch contactor pole activated the main power contactor coil.

- It supplies the motor terminals with full line voltage. and the motor starts up. For a brief period of time, the motor will draw an extremely high inrush current.

- As the motor accelerates and approaches full speed, the current begins to fall, but not significantly until the motor reaches full speed, which is around 85% of synchronous speed.

- The motor load affects the time it takes for the motor to accelerate to full speed and thus the duration of high starting current, but not the amount of starting current.

- The motor will attain full speed if the torque developed by the motor exceeds the load torque at all speeds during the start cycle.

- If the motor’s torque is less than the torque of the load at any speed throughout the start phase, the motor stop accelerating.

- If the motor torque generated by the DOL Motor starter is insufficient for the load, the motor must be replaced with one capable of producing high starting torque.

Overload Protection:

Overload problem occurs when the load connected to the motor exceeds its limit and the motor consumes an excessive quantity of current.

Overload causes the current flow to exceed acceptable limits, causing damage to the wires and motor windings. It melts the windings and may cause a fire.

To prevent the motor from being overloaded, it is necessary to employ an overload relay, which trips the power supply and prevents the system from overheating.

The overload relay helps to monitor the current and interrupts it when it surpasses a preset limit for a set length of time.

The tripping mechanism can differ depending on the application of the motor.

Overload relays for motor protection are classified as follows:

1). Thermal Overload Relay:

This sort of overload relay operates on the concept of heat generation caused by current flow. A bimetallic strip with varying thermal expansion is used to break or form a circuit based on temperature.

2). Magnetic Overload Relay:

Magnetic overload relays operate on the principle of a magnetic field generated by electricity flowing through a coil.

An excess current drawn by the motor generates a magnetic field strong enough to trip the contact terminals and interrupt the current supply.

3). Overload Relay:

An electronic relay is a solid-state device with no moving parts or contacts.

It monitors the motor current with current sensors and has an adjustable setting that allows tripping at a wide range of current ratings.

Under-Voltage Protection:

When the voltage across the motor terminals falls below a specified threshold or a power failure occurs during motor operation, the contactor coil is de-energized. As a result, the motor is disconnected from the power source.

The direct-on line starter is a simple and low-cost starter for squirrel cage induction motors.

For this starter, the beginning current drawn by the motor can be up to ten times the motor’s full-load current, and the starting torque is equal to the rated torque.

As a result, the high beginning current causes a voltage drop in the supply system to which the motor is connected.

As a result, direct on-line starters can be used to start small motors up to 5 kW in order to prevent supply voltage changes.

Characteristics of DOL Starter:

- DOL starters has a high starting current.

- DOL starters has a high starting torque.

- DOL starters creates a voltage dip in the power source.

- DOL starters has the most basic control mechanism.

- DOL starters is appropriate for motors with modest power ratings.

Why DOL starter used in an Induction motor?

A DOL (Direct On Line) starter is used to start an induction motor by providing a direct connection from the power supply to the motor.

This type of starter is simple and reliable, and it is often used for small to medium-sized motors.

In a DOL starter, the motor is connected directly to the power supply through a set of contactors (electrically-controlled switches).

When the starter is activated, the contactors close, allowing current to flow from the power supply to the motor. This causes the motor to start running.

One of the main advantages of a DOL starter is that it is very simple to use and does not require any additional control equipment.

It is also relatively inexpensive, which makes it a popular choice for small to medium-sized motors. However, it is not suitable for use with large motors, as the direct connection to the power supply can cause damage to the motor or the starter itself.

Why does an induction motor require 6 times the starting current with a DOL starter?

The following are the reasons for drawing a high starting current:

- Because the rotor current frequency is six times the stator frequency, it is very inductive. At the start, the rotor current slip is unity. As a result, the rotor reactance is extremely high

XL = 2sfs

- As a result, the induction motor’s rotor draws a lot of current when it starts.

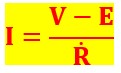

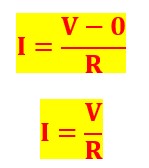

- And also furthermost, the induced voltage across the stator winding is zero, and there is no opposing EMF to the applied voltage, therefore current is limited essentially by the stator winding resistance.

Where,

V – Applied Voltage to Stator,

E – EMF induced across stator winding and

R – Stator Resistance

At starting time of the motor, E=0,

Why is the power factor of an induction motor with a DOL starting so poor?

Furthermore, the motor’s power factor is very poor, and it requires a considerable magnetising current.

When the motor is started, it takes around 6-8 times, and the amplitude of the current reduces as the motor accelerates towards its rated speed i.e., full rated speed. Even though the motor uses a lot of current when it starts, it has a very low starting torque.

DOL starting is appropriate for induction motors with low ratings.

When starting large rating induction motors with the DOL method, a high starting current might induce a voltage drop in the supply system and harm the motor.

If the capacity of the power network allows, the large rating induction motor can be started on DOL. If a big rating transformer is used for three-phase 440-volt distribution, a large rating motor up to 90 KW can be started on DOL.

However, DOL starting of a 5.5 KW motor is possible in residential connections.

Advantages of DOL Starter:

- DOL Starter is extremely simple to construct, operate, and maintain.

- It is the most affordable and cost-effective starting.

- It has a compact size and occupies up a smaller space.

- DOL Starter supplies 100% of the starting torque.

- The control circuit (green and red buttons) is simple enough for a layperson to operate.

- The system is easier to understand and troubleshoot.

- DOL Starter connects the motor’s delta winding.

Disadvantages of DOL Starter:

- The starting current is very high because it uses a full voltage starting technique.

- Because of high starting currents, it might harm motors, only low rating motors should be utilised.

- The large inrush current generates a voltage drop in the power cables, which might be hazardous to other parallel-connected equipment.

- In some circumstances, the high starting torque may be unnecessary.

- High starting torque produces mechanical stress, lowering the motor’s life expectancy.

- The starting current and torque are uncontrollable.

Applications of DOL Starter:

- DOL starters are used for motors with low power ratings where the starting current does not damage the motor windings.

- Direct online starters are used for small water pumps, conveyor belts, fans, and compressors when the starting current does not produce significant fluctuations in the line voltage.

- The squirrel cage induction motor, which is fluid coupling, can also be started with a DOL starter.