- What is meant by “Step Down Transformer”?

- Working principle of the Step Down Transformer

- Construction of the Step Down Transformer

- Working of the Step Down Transformer

- Formula

- Step Down Transformer Types

- Advantages of the Step Down Transformer

- Disadvantages of the Step Down Transformer

- Applications of the Step Down Transformer

- Function of the Step Down Transformer in the Voltage Transmission Line

- What are some ways to test a step down transformer?

- How does a step down transformer’s voltage output get calculated?

- How do choose the appropriate size step-down transformer?

- How does a step-down transformer become connected?

- Can the voltage be increased using step down transformers?

- What are some parameters that could affect a step down transformer’s performance?

- What are some of the most typical issues that arise with step down transformers, and how may these issues be rectified?

- Conclusion

Transformers are static devices because they have no moving components. Its primary function is to transfer electrical power from one circuit to another by varying the voltage and current but not the frequency.

Transformers may be classified depending on their capabilities, such as

- Step Up transformers and

- Step Down transformers.

- A stepup transformer increases the voltage from low to high, and

- A stepdown transformer decreases the voltage from high to low.

Thus, this post provides an outline of a step-down transformer’s operation and uses.

What is meant by “Step Down Transformer”?

A step-down transformer is a type of transformer that converts high output voltage and changes it into low output output voltage while increasing the amount of current that it uses.

This transformer is comprised of the primary and the secondary windings, both of which are different from one another.

Working principle of the Step Down Transformer

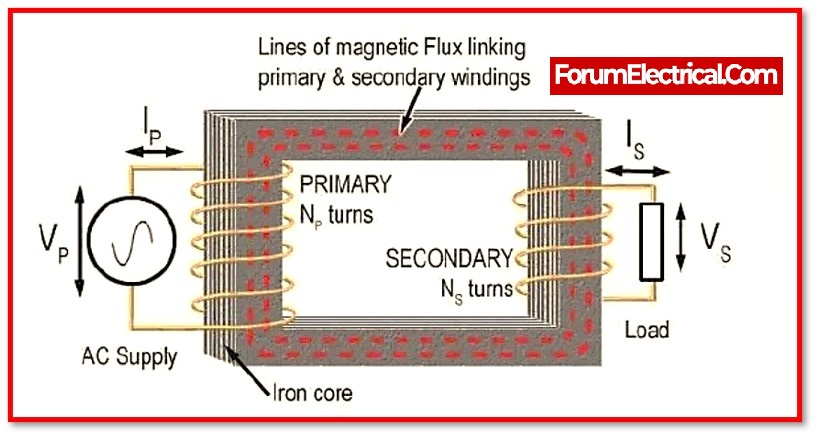

Faraday’s law of electromagnetic induction is the working principle (operating principle) of a step down transformer. In a transformer, transmission between two windings requires mutual induction.

According to Faraday’s law, when the magnetic flux linking a circuit changes, an electromotive force may be created inside the circuit that is directly proportional to the rate of change of the flux linkage.

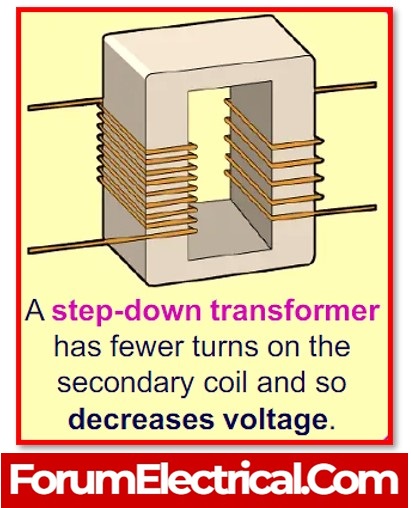

The number of windings in the transformer may be used to calculate the induced electromotive force. This is known as the turns ratio. This turns ratio determines the transformer’s capacity to reduce voltage.

When the number of windings in the secondary coil is less (low) in comparison to the primary coil, the flux linkage to the secondary coil is similarly low in comparison to the primary coil.

As a result of the low electromotive force created in the secondary coil, the voltage at the secondary winding is lower than at the primary winding.

Construction of the Step Down Transformer

A transformer is made up of the following major components:

1).Core

2). Winding

1). Core

A transformer core is made up of coils wound up on the certain material. These cores are comprised of a highly permeable substance that may transmit flux.

The core of a transformer serves as a route or channel for magnetic flux to pass freely. These cores are made of ferromagnetic materials with high permeability, such as iron.

Engineers utilise thin metallic iron sheets in transformers rather than a single solid core because a single solid core generates more eddy currents, lowering transformer efficiency.

2). Winding

Voltage transformers are wound using wires known as coils. Here, we employ wires with low resistance and high conductivity, which is essential for optimum transformer efficiency.

Copper is often used in transformer windings due to its high electrical conductivity and low resistance in compared to other materials. It is also less costly than gold, silver, & platinum.

A step-down transformer may be constructed with two or more coils coiled on the transformer’s iron core.

The ferromagnetic core is the key component of efficient transformers because it is magnetised by the primary coil and transfers energy to the secondary coil.

Finding 2-3 inches of large steel washer at a wrecking yard is a simple way to obtain a ferromagnetic coil.

a). Primary Coil

Any type of conducting wire may be used to construct the coils in the transformer, but the finest option is a magnetic wire with a gauge of 28. This is a thin copper wire that has been insulated.

To construct the primary coil, wrap the wire tightly around the washer. If necessary, wind it in layers. Count the total amount of windings & make a note of it.

b).Secondary Coil

After the winding is complete, leave the two ends exposed to connect to the power supply and wrap the wires with masking tape to keep them in place.

The secondary coil windings should be kept to a minimum while constructing this transformer.

The exact quantity is determined mostly by the required voltage, which may be computed using the transformer’s formula.

Working of the Step Down Transformer

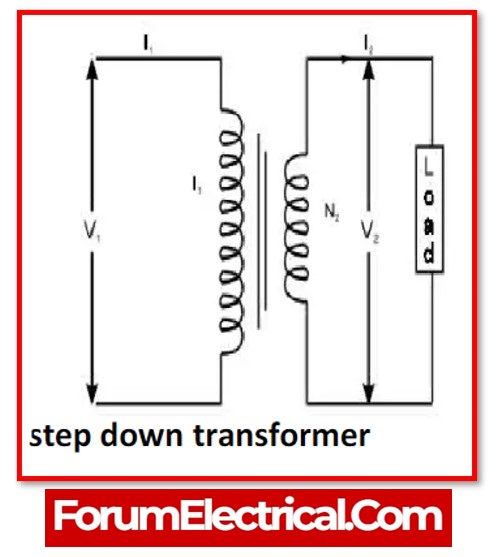

The primary coil is linked to the primary voltage, while the secondary coil is linked to the load.

As a result, the load consumes the output alternating voltage, which is either stepped up or stepped down.

The primary winding will be excited by the alternating voltage at the transformer’s input, and the winding will be circulated by an AC. As a result, the AC will cause an alternating magnetic flux to travel through the iron magnetic core to complete its path.

When the secondary winding is coupled to the alternating magnetic flux, an emf can be generated inside the secondary winding using Faraday’s Law.

The voltage strength (voltage value) at the secondary winding is mostly determined by the number of windings used to provide the flux.

As a result, the alternating voltage will be transmitted via the secondary winding without making an electrical contact with the primary winding.

Formula

The step down transformer formula is as follows:

Ns/Np = Vs/Vp

Where,

‘Ns’ – Number of windings in secondary

‘Np’ – Number of windings in primary

‘Vs’ – Number voltage in secondary

‘Vp’ – Number voltage inprimary

With this transformer, the number of secondary windings is always smaller (less) than the number of main windings.

Ns< Np

Step Down Transformer Types

Step-down transformers are categorized as

- Single PhaseStep Down Transformer,

- Center PhaseStep Down Transformer, and

- Multi TappedStep Down Transformer.

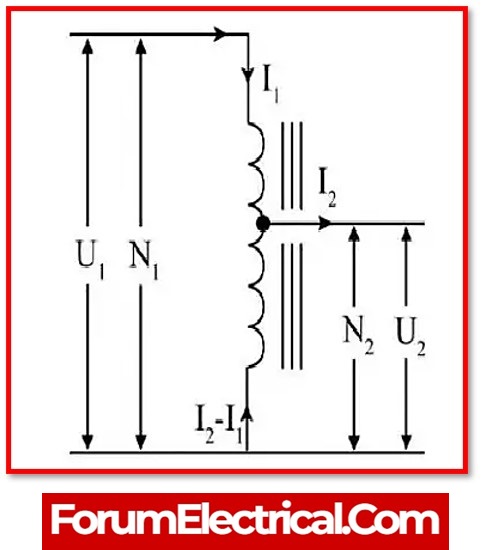

1). Single Phase Step Down Transformer

Single-phase is utilized to reduce the current and voltage ratings and also the input voltage to generate less voltage and current, such as 12V AC.

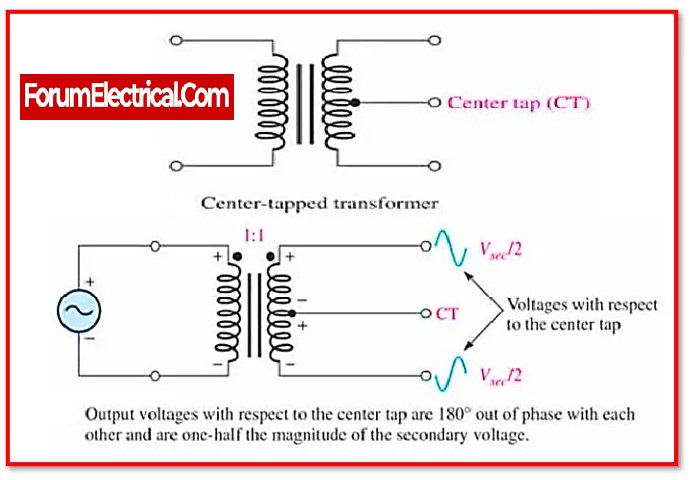

2). Center Tapped Step Down Transformer

Center Tapped consists of one primary and a center split inside the secondary, resulting in an output voltage with a center split of 12v to 0 to 12v.

3). Multi Tapped Step Down Transformer

Multi Tapped has many tappings inside the secondary winding, which are utilised to generate the desired output via secondary coils such as 0 to 12v and 0 to 18v.

Advantages of the Step Down Transformer

- Step down transformer is helpful in reducing the voltage to a level appropriate. As a result, the transmission of electricity is simplified and made more cost-effective.

- The efficiency provided by these is more than 99%.

- This gives different voltage demand requirements.

- They are inexpensive, have a high degree of reliability, and are long-lasting (durable).

Disadvantages of the Step Down Transformer

- It requires extensive maintenance, failure of which might result in transformer damage.

- Cost volatility in feedstock

- Retification of faults (flaws) requires more time.

Applications of the Step Down Transformer

- In main adapters and chargers for mobile phones, stereos, and CD players, a step down transformer is employed.

- Stepping down the voltage in a transmission line

- In welding equipment, this is accomplished by lowering the voltage and increasing the current.

- Voltage stabilisers, inverters, and other electronic devices.

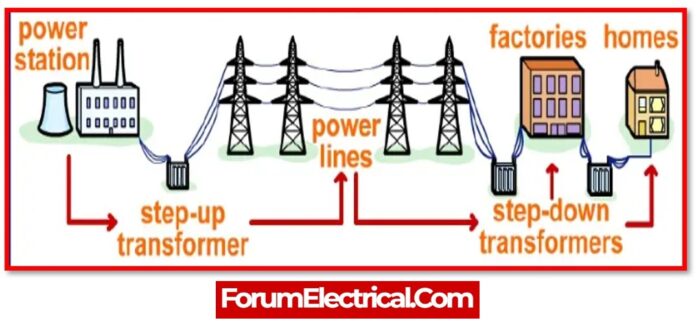

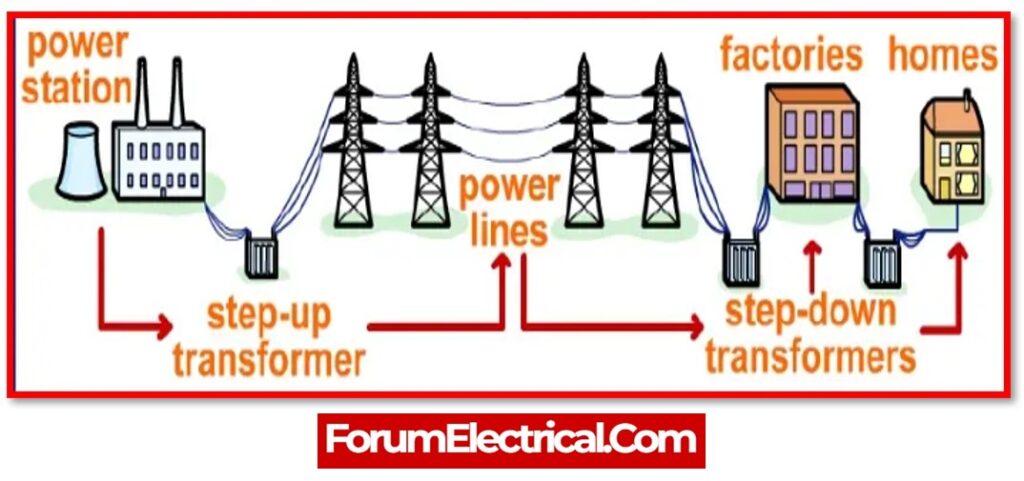

Function of the Step Down Transformer in the Voltage Transmission Line

AC power supply is generated at power plants at a peak voltage of around 440 volts, which is extremely low. A typical end user operates their house and workplace on a voltage ranging from 220V to 240V.

The voltage output of a power station is fed through a step up transformer, which raises the peak voltage from a few hundred volts to a few kilovolts. The peak voltage is measured at the power station.

The output of the step up transformer is connected to a high tension transmission line, which is responsible for carrying the power and energy across a distance.

This is done to minimise the voltage loss that occurs. As soon as this power reaches (attain) its consumption (distribution) point or end sub station, it is then lowered to the required value, which can vary between 220V and 240V, with the help of a step down transformer.

What are some ways to test a step down transformer?

There are different methods to testing a step down transformer.

1). Open circuit test

2). Short circuit test

3). Load test

4). Temperature increase test

1). Open circuit test

The voltage of primary winding is measured here with the secondary winding left open for performance compared.

2). Short circuit test

During this test, the secondary winding is purposefully shorted out, and the current in the primary winding is measured.

3). The Load Test

A load is attached to the secondary winding during this test, and the voltage & current of both the primary & secondary windings are measured.

4). Temperature increase test

This test used to measures the increase in temperature experienced by the transformer when it is subjected to loaded settings condition in order to validate that it is functioning within acceptable parameters.

How does a step down transformer’s voltage output get calculated?

The following formula may be used to compute the voltage output (Voutput) of a step down transformer:

Voutput= Vinput x (Ns/Np)

Where,

‘Ns’ – Number of windings in secondary

‘Np’ – Number of windings in primary

‘Vs or Voutput’ – Number voltage in secondary (Output Voltage)

‘Vp or Vinput’ – Number voltage in primary (Input Voltage)

How do choose the appropriate size step-down transformer?

The size of a step down transformer that is acceptable for a specific application is determined by the load’s voltage and current requirements (devices that the transformer can be powering).

One must know the load’s voltage and current ratings and choose a transformer with the primary voltage rating greater than the voltage supply and a secondary voltage rating equal to or greater than the load voltage.

The transformer’s current rating should be equal to (or) higher than load current. To prevent overloading or injuring the transformer (or) the load, it is essential to use a suitably sized transformer.

How does a step-down transformer become connected?

Typically, step-down transformers are connected in a Delta (or) Wye arrangement.

- The primary & secondary windings are linked in a triangle arrangement in a Delta design.

- The primary & secondary windings are linked in a Y-shaped arrangement in a Wye design.

The particular wiring approach will be determined by the transformer & the application. While wiring a step-down transformer, it is essential to adhere to the manufacturer’s recommendations.

Can the voltage be increased using step down transformers?

No, step down transformers are made to lower an AC power supply’s voltage. A step-up transformer is needed for increasing the voltage of an AC power source.

What are some parameters that could affect a step down transformer’s performance?

The function of a step-down transformer may be impacted by a variety of parameters, including the following:

- The quality of the components that were used in the construction of the transformer.

- The layout of the transformer’s circuitry.

- The amount of load that was put on the transformer.

- The frequency & voltage of the power source that uses alternating current.

- The temperature and the humidity of the environment.

- The presence of electromagnetic interference from the outside source (EMI).

What are some of the most typical issues that arise with step down transformers, and how may these issues be rectified?

The following are some typical issues with step down transformers:

1). Overheating

2). Humming (or) buzzing and

3). Poor voltage regulation

1) Overheating

This may occur if the transformer is overloaded, if it is utilised at frequencies that are greater than its rating, or if it is used in environments with high ambient temperatures. Reduce the load that the transformer is carrying, make sure it is operating at its rated frequency, and make sure it has enough ventilation to fix this problem.

2). Humming (or) buzzing

This may be the result of magnetic fields interacting with other electrical equipment in the vicinity or it may be the result of mechanical problems with the transformer. Either relocate the transformer so that it is not in close proximity to any other electrical equipment or have a qualified electrician check & repair the transformer for you.

3). Poor voltage regulation

This may be brought on by an improperly sized or loaded transformer, as well as by a malfunctioning transformer itself. To fix that issue, check that the connected transformer is the appropriate size and has the appropriate rating for the load. Moreover, have a trained expert assess the transformer and repair it if required.

Conclusion

The purpose of this post is to provide an outline of the step down transformer. As a result of its primary function, which is to reduce the voltage, this component may be found in almost all of the electrical equipment found in a home.