- What is a Vacuum Circuit Breaker (VCB)?

- Components of VCB

- Contact Materials of VCB

- Working Principles of Vacuum Circuit Breakers

- Construction of VCB – Vacuum Circuit Breaker

- Operating Mechanism of Vacuum Circuit Breaker (VCB)

- Working of Vacuum Circuit Breaker (VCB)

- Types of Vacuum Circuit Breakers (VCBs)

- Current Chopping in Vacuum Circuit Breakers (VCB)

- Vacuum Arc Recovery for Vacuum Circuit Breaker

- Characteristics of Vacuum Circuit Breakers

- Vacuum Circuit Breaker (VCB) Testing

- Applicable Standards for Vacuum Circuit Breaker (VCB)

- Difference between Vacuum Circuit Breaker and Vacuum Contactor Unit

- Vacuum Circuit Breaker vs Vacuum Contactor Unit

- Advantages of Vacuum Circuit Breaker

- Disadvantages of Vacuum Circuit Breaker

- Applications of Vacuum Circuit Breaker

A circuit breaker is a device that stops an electric circuit to prevent inappropriate current from flowing due to a short circuit, which is usually caused by an overload. Its main function is to interrupt current flow when a fault is detected. Circuit breakers protect electrical systems from harm caused by over-currents & short circuits. Vacuum circuit breakers, or VCBs, employ a vacuum to extinguish the arc formed when the circuit is tripped & the contacts come apart. VCBs are rapid and effective, making them an excellent choice for medium- & high-voltage systems. Below, we will look at how VCBs function, how they are used, & some of their advantages and disadvantages.

What is a Vacuum Circuit Breaker (VCB)?

A vacuum circuit breaker (VCB) is a circuit breaker which utilizes a vacuum medium to quench the arc. The function of turning on and closing current carrying contacts, as well as linked arc interruption, takes done in a vacuum chamber within the breaker, known as a vacuum interrupter.

A vacuum circuit breaker is one that uses vacuum as the arc quenching medium because vacuum has a high insulating strength because of its superior arc quenching capabilities. This is appropriate for most standard voltage applications since higher voltage vacuum technology was developed but is not economically feasible.

The performance of vacuum circuit breakers is mostly determined by the material chosen for current-carrying contacts, such as Cu/Cr. It is mostly used for medium voltage applications that covers from 11 to 33 kV.

Components of VCB

VCBs have many of the identical components as ordinary circuit breakers, but they also include a vacuum interrupter. The major components are outlined below:

- Fixed Contact

- Movable Contact

- Vacuum Interrupter

- Actuator Mechanism

Fixed Contact: Electricity enters the circuit and passes through a fixed, stationary contact. This contact remains in situ regardless of whether the circuit is open (or) closed.

Movable Contact: Current flows from fixed to movable contacts. If the circuit is tripped, the movable contact flows away from the fixed contact, cutting off the flow of power.

Vacuum Interrupter: A vacuum interrupter creates an arc in a VCB. A vacuum is a great insulator and will swiftly extinguish the arc.

Actuator Mechanism: The actuator mechanism is linked to both the tripping mechanism & the movable contact. When the circuit is tripped, it causes the actuator mechanism to move circuits away.

Contact Materials of VCB

The contact material for VCBs must have the following qualities.

- High density.

- To prevent overheating, contact resistance should be low and electrical conductivity high.

- Thermal conductivity is high to swiftly dissipate the tremendous heat generated during arcing.

- The thermionic function needs to be high to enable early arc destruction.

- There must be a low tendency to weld

- Lower current cutting level.

- High arc resistance capabilities.

- A boiling point needs to be high to reduce arc erosion.

- Gas content must be below to ensure a longer service life.

- Low vapor pressure is required to be adequate to reduce the amount of undivided metal vapor in the chamber.

Working Principles of Vacuum Circuit Breakers

Circuit breakers frequently utilize a thermal & magnetic trip to detect both overcurrent and short circuits. When the circuit trips, it initiates a series of measures within the insulating material. A vacuum serves as the insulating medium for a VCB.

When the circuit trips, the actuator mechanism causes the movable contact to break its connection with the fixed contact. The broken connection ionizes the metal vapors, resulting in an electrical arc between the two contacts. This arc can destroy equipment & must be extinguished immediately, especially in high-voltage conditions.

The arc extinguishes fast in a vacuum because it is a good insulator. Within a vacuum, ions, vapors, & electrons all produce at the same rate.

The ions condense on the exterior of the contacts, & the insulating vessel quickly regains its dielectric strength. The arc disappears practically immediately after it emerges.

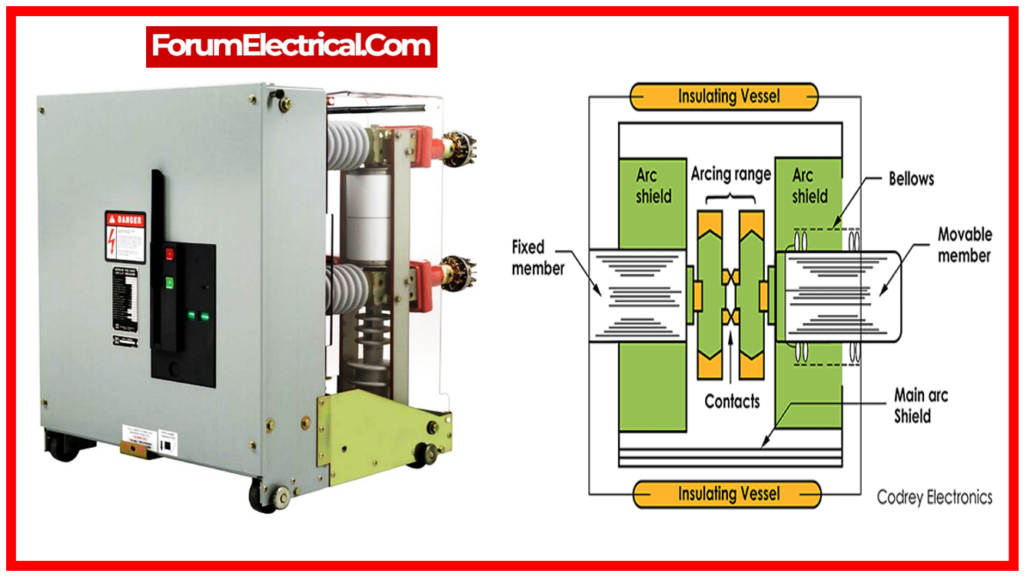

Construction of VCB – Vacuum Circuit Breaker

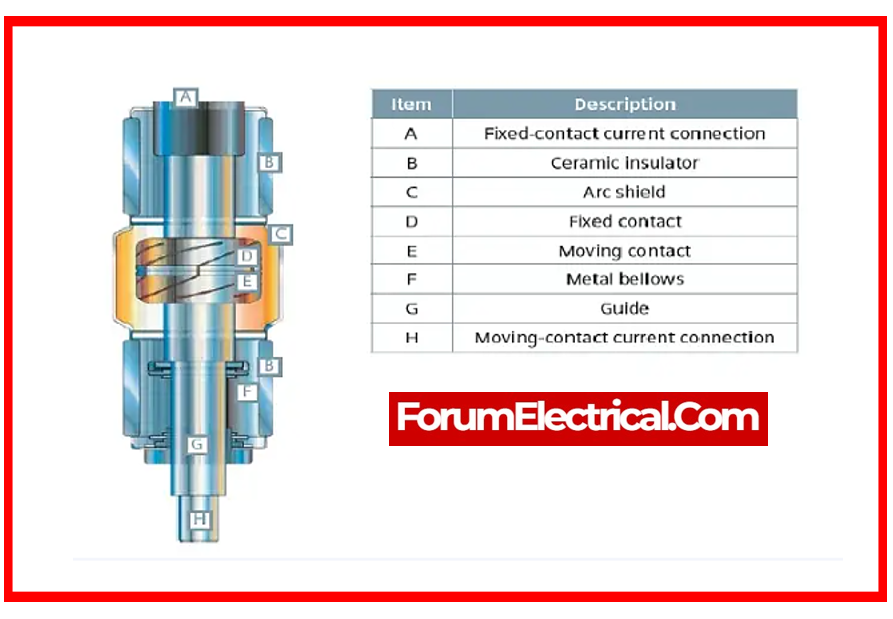

The design is quite basic when compared to other circuit breakers. Their construction is separated into three parts:

- Fixed contacts,

- Moving contacts, and

- An arc shield that is located within the arc interrupting chamber.

The exterior envelope of a vacuum circuit breaker is constructed of glass because it facilitates inspection of the breaker from the outside after operation.

If the glass turns milky from its original appearance of silvery mirror, it means that the breaker loses vacuum.

The arc shield contains both the breaker’s fixed and movable contacts. When a vacuum interrupter is sealed off, the pressure within is kept at around 10-6 torr.

The circuit breaker’s movable contacts move 5 to 10 mm, depending on the operating voltage.

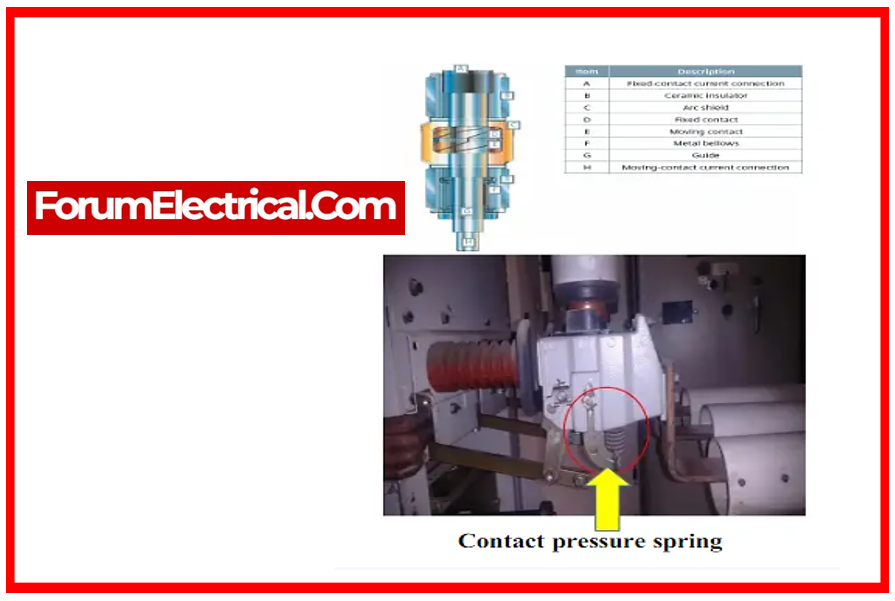

The movable contacts are moved using a metallic bellows composed of stainless steel.

The construction of the metallic bellows is essential since the longevity of the vacuum circuit breaker is dependent on the component’s ability to execute repeated operations satisfactorily.

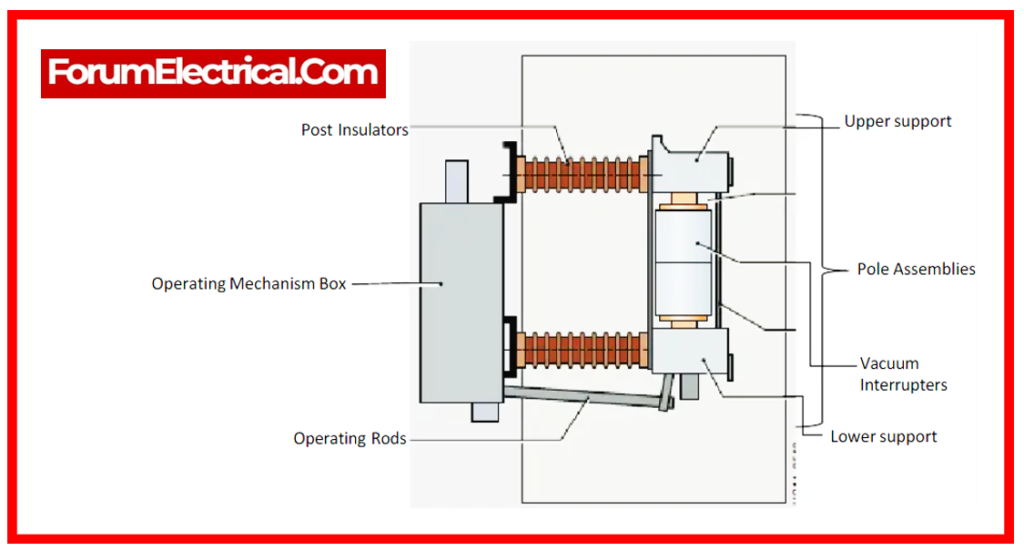

Operating Mechanism of Vacuum Circuit Breaker (VCB)

When it comes to a vacuum circuit breaker,

- The extinguishment of the arc does not require the use of any human medium.

- Extremely little weight is carried by the contact that is moving.

- During the opening phase, the contact has to move a very low distance.

- In terms of switching velocity, it is slow.

In order for the VCB’s working mechanism to function properly, all of these reasons demand a limited amount of energy.

The interlock signal of the relay produces this energy, which is immediately accessible.

Built-in motion action (or) pre-loaded operating springs are the means by which these requirements for the working mechanism are carried out.

Existing latches, nozzles, contact interlocking arrangements, and safety devices are all included in the circuit breaker. These are all designed to ensure that the contacts remain in the closed state.

Single-break operation is the type performed. It is not necessary to do any additional maintenance beyond what is normally required because the mechanism that operates is simple.

Working of Vacuum Circuit Breaker (VCB)

When the contacts are separated due to abnormal conditions, an arc is formed between them. The arc is caused by the ionization of metal ions and is highly dependent on the material of the contacts.

The arc interruption in vacuum interrupters differs from other types of circuit breakers.

The separation of contacts produces the release of vapor, which is contained within the contact space. It is comprised of positive ions that have been released from the contact substance.

The vapor density is determined by the current in arc. The speed of vapor release decreases with decreasing current, and the medium regains its dielectric strength if the vapor density decreases while the current is zero.

If the current to be interrupted is relatively minimal in a vacuum, the arc takes numerous parallel levels. The whole current is separated into numerous parallel arcs, which oppose one another and spread across the contact surface. This is known as a dispersed arc, which is easily disrupted.

At high current values, the arc becomes concentrated in a limited spot. It rapidly vaporizes the contact surface. The arc can be interrupted if it remains diffused. If it is rapidly withdrawn from contact surface, the arc will strike again.

Arc extinction in VCB is affected by contact composition, shape, and metal vapor prediction. The arc’s direction is continually moving to ensure that the temperature at any given place is not too high.

Following the final arc interruption, there is a rapid increase in dielectric strength, which is characteristic of the vacuum breaker. Re-strick-free performance makes them suitable for capacitor switching.

The limited current is interrupted prior to its normal current reaches zero, which may result in chopping, the level of which is determined by the substance of contact.

Types of Vacuum Circuit Breakers (VCBs)

Vacuum circuit breakers (VCBs) are classified according to their use, structure, and operating mechanism. Here are the major types:

- Tank-Type Vacuum Circuit Breakers (SF6 Gas Insulation)

- Dry-Air Insulated-Dead Tank Vacuum Circuit Breaker

- Insulator-Type Vacuum Circuit Breaker

- Insulator-Type Two-Pole Vacuum Circuit Breakers

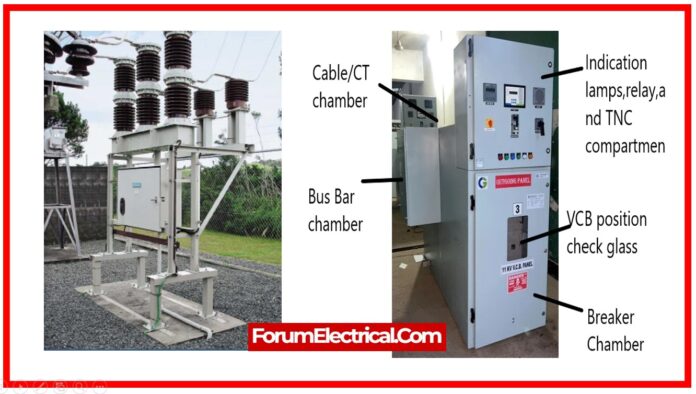

- Outdoor Vacuum Circuit Breaker (OVCB)

- Indoor Vacuum Circuit Breaker (IVCB)

- Medium-voltage vacuum circuit breakers

- High Voltage Vacuum Circuit Breakers

- Fixed Vacuum Circuit Breakers

- Draw-Out Vacuum Circuit Breakers

- Vacuum Circuit Breakers have Embedded Poles

- Modular Vacuum Circuit Breakers

- Generator Vacuum Circuit Breakers

- Railway Vacuum Circuit Breakers

- Oil Vacuum Circuit Breaker

- Axial Magnetic Field Vacuum Breaker

- Phase-segregated vacuum breaker

- Hybrid vacuum circuit breaker

Tank-Type Vacuum Circuit Breakers (SF6 Gas Insulation)

This form of VCB uses a tank filled with the sulfur hexafluoride (SF6) gas as an insulator and arc-quenching medium. It is often utilized in high-voltage applications because of its strong insulating qualities & high interrupting capability.

Dry-Air Insulated-Dead Tank Vacuum Circuit Breaker

Despite SF6 gas-insulated VCBs, this type of device use dry air as an insulation medium. It helps the environment by avoiding the consumption of SF6 gas, which has a strong global warming potential. These breakers are ideal for medium- to high-voltage systems.

Insulator-Type Vacuum Circuit Breaker

In this construction, the vacuum interrupter is covered in an insulating substance like porcelain or resin. This architecture offers both electrical insulation & mechanical support, making it ideal for medium-voltage applications that require dependability.

Insulator-Type Two-Pole Vacuum Circuit Breakers

These VCBs have a two-pole construction, with each pole covered in insulating material. This arrangement provides improved insulation and mechanical robustness, making it appropriate for medium-voltage applications that require a greater level of reliability & safety.

Outdoor Vacuum Circuit Breaker (OVCB)

These VCBs are designed for outdoor applications and have a waterproof and sturdy construction, ensuring reliable performance in adverse conditions.

Indoor Vacuum Circuit Breaker (IVCB)

These VCBs are specifically intended for indoor use, with compact designs & efficient performance in controlled settings.

Medium-Voltage Vacuum Circuit Breakers

These VCBs are often utilized in medium-voltage applications and provide dependable performance in a variety of industrial and commercial settings.

High Voltage Vacuum Circuit Breakers

These VCBs are intended for high-voltage applications, with exceptional arc extinguishing capabilities & dependable reliability in critical power systems.

Fixed Vacuum Circuit Breakers

These VCBs are permanently placed and provide a predetermined configuration for certain applications, ensuring dependable performance with low maintenance requirements.

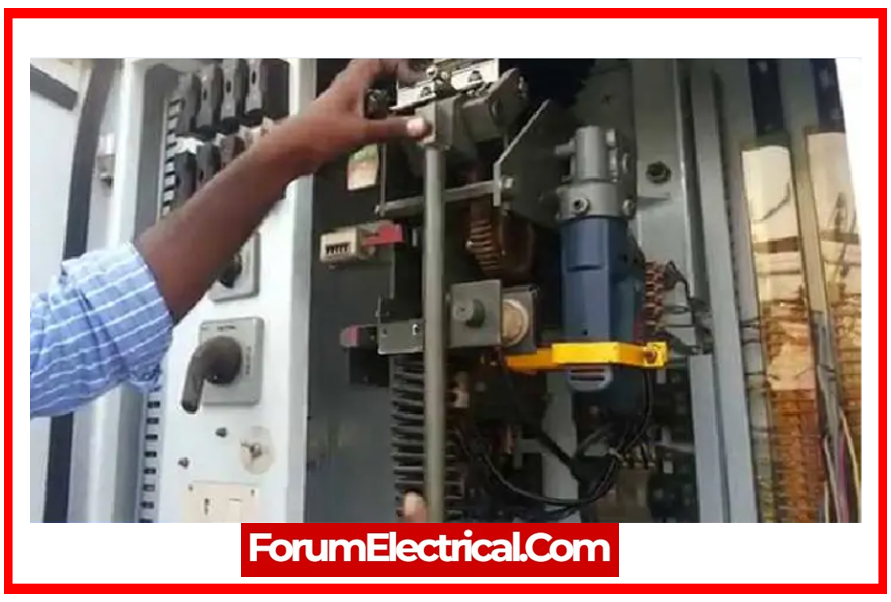

Draw-Out Vacuum Circuit Breakers

These VCBs have a draw-out design and are easy to maintain and replace, making them ideal for applications that require minimal downtime.

Vacuum Circuit Breakers Have Embedded Poles

These VCBs have incorporated poles for small designs and efficient functioning in space-constrained applications.

Modular Vacuum Circuit Breakers

These VCBs have a modular architecture that allows for simple expansion & customization based on individual application needs.

Generator Vacuum Circuit Breakers

These VCBs are specifically developed for generator applications, providing dependable performance and circuit protection.

Railway Vacuum Circuit Breakers

These VCBs are intended for railway applications, providing dependable performance and protection to railway signaling & traction systems.

Oil Vacuum Circuit Breaker

Vacuum interrupters are used in conjunction with an insulating oil medium within the tank. An older design that is no longer widespread because to environmental concerns about oil.

Axial Magnetic Field Vacuum Breaker

Vacuum interrupters using an axial magnetic field for quicker arc extinction. Suitable for medium voltage operations up to 72.5 kV.

Phase-Segregated Vacuum Breaker

Hybrid Vacuum Circuit Breaker

Combines a vacuum interrupter and an SF6 (or) air blast insulating/quenching system. More efficient than pure vacuum (or) SF6 arrangements.

Current Chopping in Vacuum Circuit Breakers (VCB)

Current chopping in a vacuum circuit breaker is determined by the contact material’s electron emission characteristics and vapor pressure. The chopping level is also impacted by thermal conductivity; the lower the thermal conductivity, the lower the chopping level.

It is possible to minimize the current level at which the chopping happens by using a contact material that emits enough metal vapor to allow the current to drop to a very low (or) zero value, but it is rarely done because it has a negative impact on the dielectric strength.

Because of the instability of the arc column, current chopping in vacuum circuit breakers happens mostly in oil circuit breakers and in the air.

It is possible to reduce the current level at which the chopping happens by using a contact material that provides enough metal vapor to allow the current to approach an extremely low value; however, this is not commonly done because it has a negative impact on dielectric power.

The recovery of dielectric strength is due to the vaporized metal, which is concentrated between the contacts and diffuses rapidly because of the lack of gas molecules.

Vacuum Arc Recovery for Vacuum Circuit Breaker

High vacuum has exceptionally high dielectric strength. At zero current, the arc quickly dissipates & the dielectric strength is established. Due to the lack of gas molecules, vaporized metal concentrates between contacts and diffuses quickly, restoring dielectric strength. After an arc interruption, the recovery strength is 1 kV/µs for a 100A arc current.

Because of this previously mentioned feature, vacuum circuit breakers can easily handle significant recovery transients associated with the short-line faults.

Characteristics of Vacuum Circuit Breakers

- In comparison to other types of the circuit breakers, the vacuum circuit breaker’s insulating medium has a high arc extinction rating.

- The vacuum interrupter has a pressure of around 10-4 torrent and contains relatively few molecules.

- Compared to other insulating media used in circuit breakers, the circuit breaker is an enhanced dielectric medium. It is superior to other media except for SF6 and air since they are employed at high pressure.

- When an arc is opened individually by moving the contacts in a vacuum, it will break at the main current zero. These breakers have a thousand times higher dielectric strength than others due to arc disruption.

- These features will improve the circuit breakers’ performance, reduce their weight, and reduce their cost. These circuit breakers have a longer life expectancy than ordinary circuit breakers and require no maintenance.

Vacuum Circuit Breaker (VCB) Testing

Circuit breaker testing is typically used to evaluate the performance of individual switching mechanisms as well as the timing of the entire tripping system.

Once vacuum interrupters are constructed and utilized in the field, three types of tests are employed to validate their function:

- Contact Resistance Testing,

- High Potential Withstand Testing, and

- Leak-Rate Testing.

Applicable Standards for Vacuum Circuit Breaker (VCB)

Standards for vacuum circuit breakers (VCBs) are critical to ensuring their safety, dependability, and performance in electrical systems. Several global standards organizations & regulatory agencies develop recommendations & specifications for VCBs. Some of the major standards for vacuum circuit breakers are:

- IEC 62271-100: This standard covers the criteria for AC circuit breakers, includes vacuum circuit breakers, with rated voltages greater than 1 kV and up to and including 52 kV.

- ANSI C37.04: This standard specifies the ratings, construction, testing, & operation of indoor & outdoor distribution VCB with rated voltages of up to 38kV.

- ISO 9001: This standard defines quality management system standards for enterprises that develop, manufacture, and test vacuum circuit breakers to assure consistent product quality.

- NEMA AB 3: This standard provides ratings & requirements for indoor medium-voltage vacuum circuit breakers with rated voltages ranging from 2.4 kV to 38kV.

- IEEE C37.013: This standard establishes rules for the performance & testing of high-voltage AC (HVAC) circuit breakers, including VCB, with rated voltages greater than 1000 V.

Difference between Vacuum Circuit Breaker and Vacuum Contactor Unit

Vacuum Circuit Breaker vs Vacuum Contactor Unit

A vacuum circuit breaker trips when an error occurs, such as an earth fault, short circuit, or over/under voltage. A contactor is frequently connected in series with a fuse to prevent fault current.

The key differences between a vacuum circuit breaker and a vacuum contactor unit are outlined below based on their respective properties.

| Vacuum Circuit Breaker | Vacuum Contactor Unit |

| Switching capacity refers to the ability to switch currents from low values to full system short-circuit current. | Switch currents from extremely low values to disrupt the capability of vacuum contactors without fuses. Fuses work for higher currents than the interrupting capability of the vacuum contactor alone, up to the disrupting capability of the fuse. |

| Mechanical endurance is quite high. | Mechanical endurance is quite high, with 1,000,000 processes at up to 630A. |

| Electrical endurance is high, similar to a vacuum, ranging from 10,000 to 50,000 operations at the rated continuous current. Vacuum operations range from 30 to 100 at full short-circuit rating. | Incredibly high switching continuous current ranges from 450K to 1,000K operations at up to 630 amps. Short-circuit current switches require fuses to be replaced due to lack of documented durability data. |

| These are not suitable for extreme endurance applications. | These are utilized for operations with high frequency switching. |

| It is costly. | The price is reasonable. |

| The cost of maintenance is medium. | Its maintenance is inexpensive. |

Advantages of Vacuum Circuit Breaker

- When compared to traditional circuit breakers, VCB have a more insulating medium for arc extinction.

- It has excellent insulating characteristics.

- Vacuum is a better dielectric medium than other insulating materials utilized in circuit breakers.

- They often have a far longer service life than any other type of circuit breaker and require very no maintenance.

- They are much more effective, compact, and less expensive.

- A vacuum circuit breaker requires no additional oil or gas filling.

- The breakers are compact and self-contained.

Disadvantages of Vacuum Circuit Breaker

- Circuit breaker vacuum manufacture necessitates specialized technology.

- Additional surge suppressors are necessary for the interruption of the low magnetizing currents within a specific range.

- The vacuum loss due to transit damage (or) failure renders the entire interrupter useless and unable to be repaired on site.

Applications of Vacuum Circuit Breaker

- VCBs are widely employed in power production plants and substations for protecting electrical equipment & systems from overcurrent & short circuits.

- Industrial applications include the protection of motors, transformers, & other electrical equipment.

- VCBs are utilized to protect overhead lines, traction systems, & signaling equipment.

- Commercial buildings employ them to protect their electrical distribution systems.