- What is a steam turbine?

- Steam turbine components

- What is the Operation of a Steam Turbine?

- Classification of Steam Turbine

- Based on steam

- Based on action of steam

- Based on Stages

- Advantages of steam turbine

- Disadvantages of steam turbine

- Applications of Steam Turbine

- Failure of steam turbine

- Steam Turbine Losses

- Some Useful Questions related to Steam Turbines

What is a steam turbine?

A steam turbine is a mechanical device that converts thermal energy from pressured steam into mechanical work. Because the turbine provides rotating motion, it is well suited to powering electrical generators.

The steam turbine is a type of heat engine that improves thermodynamic efficiency by using many stages in the expansion of the steam, resulting in a closer approach to the ideal reversible expansion process.

Because the turbine produces rotary motion, it can be linked to a generator and converted into power. These turbogenerators are the basis of thermal power plants that can be powered by fossil fuels, nuclear fuels, geothermal energy, or solar energy.

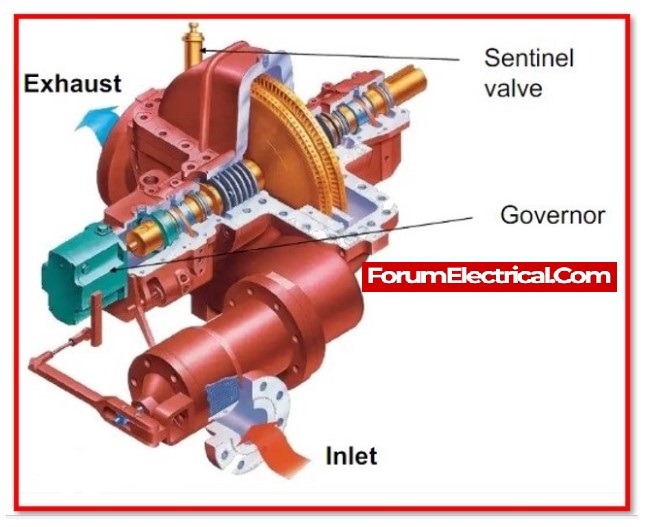

Steam turbine components

1). Rotor and Blades

Steam turbine blades resemble propeller blades but are crafted from high-performance alloys to withstand the extreme temperatures, pressures, and velocities of the steam that flows past them.

The rotor, a robust axle running through the turbine’s core, transfers energy from the turbine to an electricity generator (or) whatever else the turbine is driving. The turbine’s blades are its most vital component, as their shape and size determine the amount of steam’s kinetic energy is converted into rotational energy and used to drive the rotor’s rotation. Rotating blades on the rotor of a turbine cause the rotor to rotate when the steam passes through. The rotor and its blades are protected by a hard alloy steel shell which is capable of withstanding high pressures and temperatures.

2). Impulse and reaction turbines

Some turbines have whirling blades that resemble buckets. The buckets are moved about by high-velocity steam jets that emerge from specially designed nozzles and then rebound to the other side at high speed but has low pressure when compared to the incoming jet. An impulse turbine, so named because of its efficiency in harnessing the power of superheated steam, is the type of turbine most commonly used in such applications.

A reaction turbine is a type of turbine that uses a second set of stationary blades mounted on the inside of the turbine casing to generate power. These assist in accelerating the steam and directing it onto the rotating blades at the correct angle, allowing the steam to exit the turbine at a lower temperature and pressure but with essentially the same speed with which it arrived.

Steam loses some of its kinetic energy as it expands through the turbine, and this is true whether the turbine is stationary or spinning. All of the steam’s wasted heat and motion would be recovered by the turbine and turned into usable motion if only conditions were optimal i.e., making it spin around. However, like with any machine, the turbine may experience some overheating, steam may escape, and other inefficiencies are inevitable.

3). Alternate Components

The rotor and blades of a turbine are not the only components necessary for operation, though i.e., usually a set of nozzles that direct steam onto either the stationary or rotating blades.

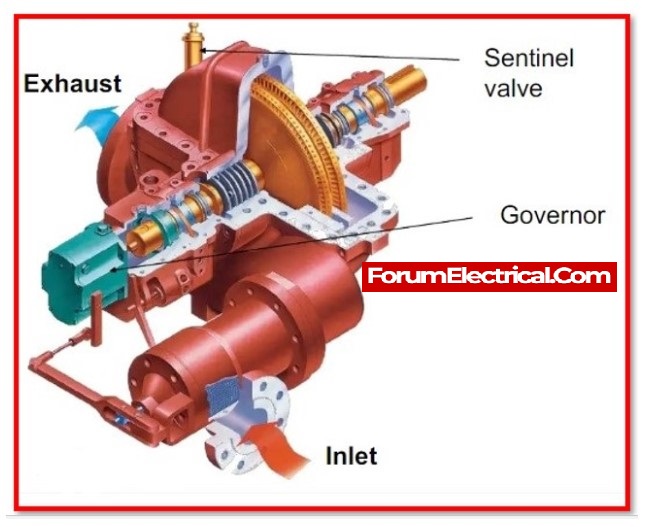

To produce as much or as little electricity as is required at any one time, steam turbines require a speed-control system. It is not simple to reduce the heat output of the gigantic furnaces that power most steam turbines, which are often found in massive power plants. However, a power plant’s load can change rapidly and substantially. Therefore, steam turbines must manage variable output despite relatively constant steam intake. Valve openings that prevent all of the steam from entering the turbine are the simplest approach to control the speed.

The term “stage” refers to a collection of blades. They also have steam inlets (which are often a series of nozzles), as well as steam outlets. The safe operation of the turbine is governed by a pair of separate and distinct devices that are known as governors.

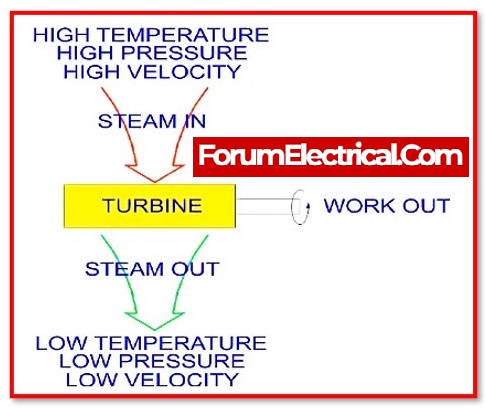

What is the Operation of a Steam Turbine?

Steam provides the motive force for a steam turbine. In a steam turbine, when hot, gaseous steam flows past the rotating blades, the steam expands and cools, releasing the majority of the energy it once contained. The blades are kept in a constant motion by the steam. The majority of the steam’s potential energy is thereby converted into kinetic energy by the blades. After then, the turbine is pushed to use to power a generator, which ultimately results in the generation of electricity.

The turbines are coupled to a generator that consists of an axle and, in turn, generates energy by means of a magnetic field that results in the production of an electric current.

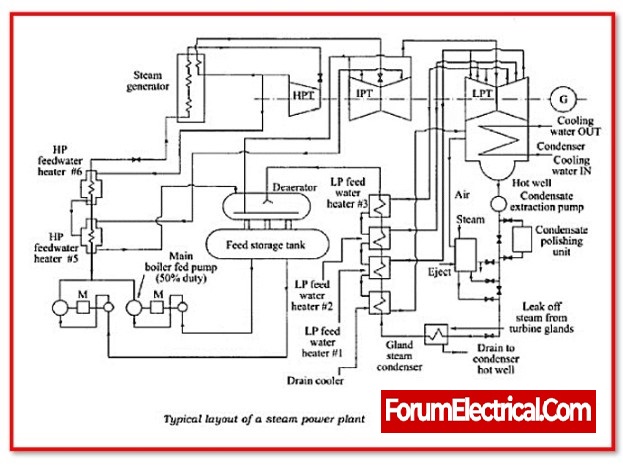

Classification of Steam Turbine

Steam turbines are categorised into several types based on their purpose and working pressures. The characteristics of steam are influenced by the industrial use of a turbine. For a steam turbine to operate, there must be a pressure difference between the steam source and the exhaust. This classification comprises the following terms:

Based on steam

1). Condensing Steam Turbine,

2). Back-pressure Steam Turbine,

3). Reheat Steam Turbine and

4). Steam Extraction Turbine

1). Condensing Steam Turbine

Thermal power plants often use condensing steam turbines. Because of the huge enthalpy difference between the initial (6MPa; 275°C; x = 1) and final (0.008MPa; 41.5°C; x = 0.9) steam conditions, a condensing steam turbine extracts the most energy from steam. A surface condenser condenses exhaust steam from the low-pressure stages of the main turbine which decreases the temperature and pressure of exhausted steam. Steam condenses over cooling system water tubes.

Decreasing turbine exhaust pressure increases net work per cycle but lowers exit steam vapour quality.

The condenser in a thermal power plant maintains the lowest turbine exhaust pressure. The condenser maximises steam energy extraction, increasing net work and thermal efficiency. Condenser pressure also has engineering limits:

- Reduced turbine exhaust pressure lowers vapour quality (or dryness fraction). Low-quality steam can harm steam turbine blades;thus, expansion must be stopped.

- The last ends of the low-pressure stage of the steam turbine need big blades because decreasing the turbine exhaust pressure increases the specific volume of exhausted steam.

In a typical condensing steam turbine, exhausted steam condenses in the condenser at 0.008 MPa (41.5°C). Point F is partially condensed steam, usually around 90%. The ambient air conditions affect condenser pressure, air temperature, pressure, and humidity for atmospheric cooling water temperature and flow rate.

The power conversion system’s thermal efficiency falls as ambient temperature rises because exhausted steam pressure rises proportionally (T = 14°C). Thus, while thermal power remains constant, power plant electrical output may vary with environmental conditions.

Steam ejectors or vacuum pumps take non-condensable gases from the surface condenser and eject them to the atmosphere, which raises the condenser’s pressure.

Saturation pressure, such as 0.008 MPa at 41.5°C, is the lowest practical condenser pressure. Due to condensers’ finite size and efficiency, there is always a 14°C temperature difference between the condenser and ambient temperatures.

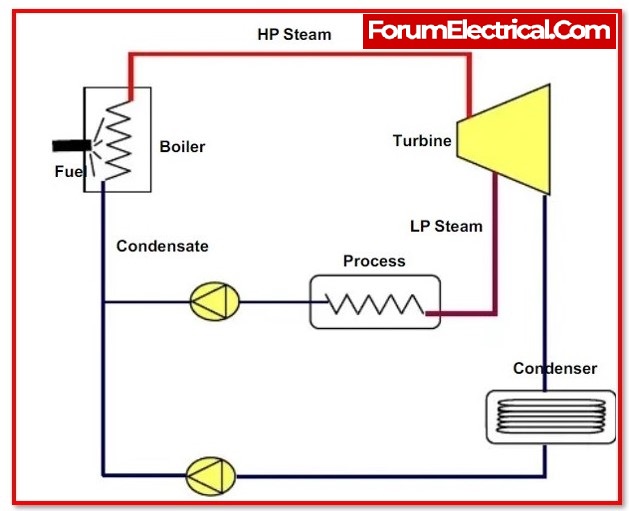

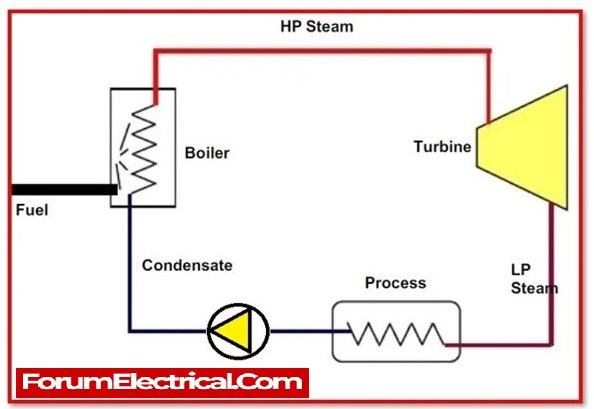

2). Back-pressure Steam Turbine

Process steam uses non-condensing back-pressure steam turbines. Steam powers various industrial processes. Process steam’s advantages make it a desirable energy source:

- High-heat capacity

- Transportability

- Low-toxic

Back-pressure steam turbines create process steam and mechanical work (or electrical energy). Back-pressure turbines raise boiler-supplied live steam to process pressure. A valve adjusts exhaust pressure to process steam pressure. Refineries, district heating units, pulp and paper factories, and desalination plants use back-pressure turbines to generate vast amounts of low-pressure process steam. Back-pressure turbines create power proportional to process steam.

3). Reheat Steam Turbine

Thermal power plants nearly entirely use reheat turbines. Steam reheats between high-pressure and low-pressure turbines in all turbines. Reheat increases thermal efficiency by supplying more heat at a cycle peak temperature. The reheater splits the turbine into multiple stages. Since each warming stage increases cycle efficiency by half, more than two are unnecessary.

The turbine’s high-pressure and low-pressure stages drive a common generator on the same shaft but have distinct casings. A reheater extracts flow after partial expansion, heats it to peak temperature in the heat exchanger, and passes it to the low-pressure turbine. Low-pressure turbines complete expansion.

4). Steam Extraction Turbine

All turbines use extraction. When needed, steam can be collected from the turbine before it enters the extraction turbine. Extracted steam from back-pressure turbines can be used in numerous industrial processes or to improve the thermodynamic cycle. Heat regeneration is the second condition.

Heat regeneration reduces boiler fuel use, hence most big steam turbines are extraction turbines. Transferring heat (partially expanded steam) from the steam turbine’s high-temperature portions to the feedwater. Steam contains mostly latent heat of vaporisation. A valve can regulate extraction flows.

Based on action of steam

1). Impulse Turbine and

2). Reaction Turbine

1). Impulse Turbine

The blades, which are rotating, look like deep buckets. The blades are pushed around with a sequence of impulses by high-velocity jets of incoming steam from finely formed nozzles. These jets then bounce off to the other side with a similar pressure but significantly decreased velocity.

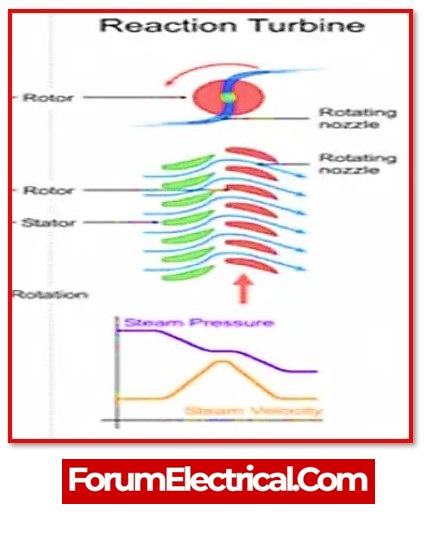

2). Reaction Turbine

A reaction turbine has a second set of stationary blades that are mounted to the interior of the turbine case. This second set of blades does not rotate. This help to speed up the steam and force it onto the rotating blades at just the correct angle, which is necessary before the steam can evaporate, which would result in a decrease in temperature and pressure.

Based on Stages

1). Single Stage Steam Turbine and

2). Multiple Stage Steam Turbine

1). Single Stage Steam Turbine

Single stage steam turbine is used in conditions with a low flow of steam. Installations that make use of the heat produced by turbine exhaust for the central heating of process technology provide significant financial advantages. In every type of turbine, the speed at which the spinning blade is moving is directly proportional to the speed at which steam is moving over the blade. If the steam is only expanded in one stage from the pressure in the boiler to the pressure at the exhaust, then its velocity needs to be exceptionally high. For a single-blade ring to function, the blades would need to be extremely enormous, and the ring’s rotational speed would need to be around 30,000 RPM, which is impractically high.

- Minimal initial cost,

- Simple maintenance, and

- Small power output

are some advantages. Because of the design of the turbine and the resistance material used, saturated steam can be used.

2). Multiple Stage Steam Turbine

The multiple stage steam turbine implies that each stage slows down or reduces the pressure of the steam by only a relatively small amount. This reduces the forces on the blades, which is an important factor for a machine that may have to run for years without stopping. Similarly, this by more improves the overall power output of the turbine.

Advantages of steam turbine

- They are highly reliable, especially when sustained high-power output is required.

- They produce fewer vibrations than reciprocating engines.

- They require lower mass flow rates than gas turbines.

- When compared to reciprocating engines, they have an extremely high power-to-weight ratio.

- When compared to reciprocating engines, thermal efficiency is often high.

- Because it is a rotary engine, it is more suited to powering an energy generator.

Disadvantages of steam turbine

- When compared to reciprocating engines, they are less responsive to changes in power demand.

- They require a longer start-up time than gas turbines and reciprocating engines.

- Steam turbines are less efficient than reciprocating engines in part-load applications.

Applications of Steam Turbine

1). Chemical Manufacturing

Steam turbines are integrated in the power generation process, providing heat and electricity to drive various processes in the chemical and pharmaceutical sectors.

2). Waste Treatment Plants

Steam turbines contribute to the power required to extract energy from waste.

3). Oil and gas

Steam turbines are used in a variety of oil and gas applications as a pump drive or a compressor.

4). Sugar refineries

Steam turbines, which provide high levels of efficiency and long-term operation, are utilised to generate green carbon-dioxide energy from bagasse.

Failure of steam turbine

It may fail under the following conditions:

- Turbine over-speeding condition.

- Condenser vacuum is low.

- Failure of the lubricating system.

- High turbine vibrations.

Steam Turbine Losses

A steam turbine is not an effective heat engine. Energy losses tend to reduce a turbine’s efficiency and work output. The following factors contribute to this inefficiency.

1). Residual Velocity Loss

The velocity of the steam leaving the turbine must be an exact value. The energy loss caused by steam’s absolute departure velocity is proportional. A multi-stage turbine can help to reduce this type of loss.

2). Presence of Friction

In thermodynamic systems or heat engines, frictional losses by particular components, such as nozzles or turbine blades, account for a portion of the overall cycle inefficiency.

3). Steam Leakage

The turbine rotor and casing cannot be completely isolated. Some steam escapes from the chamber without accomplishing any helpful work.

4). Mechanical Friction Loss in Bearings

Each turbine rotor is supported by two bearings, implying that there are two bearings between each turbine module.

5). Pressure drops in regulating valves and steam lines

The throttle-stop valves and control valves between the steam generators and the main turbine are known as the main steam line isolation valves (MSIVs). Minor losses, like pipe friction, are roughly proportional to the square of the flow rate. Flow rates in main stream lines are often very high. Although throttling is an isenthalpic operation, the enthalpy drop available for work in the turbine is reduced as the vapour quality of the exit steam improves.

6). Losses as a result of poor steam quality

The exhausted steam is at a pressure far below atmospheric, and it is partially condensed, with a quality near 90%. When condensed water is sprayed onto the blades, the higher the content of water droplets, the faster the impingement and erosion of the blades.

7). Radiation Loss

With intake conditions of 6 MPa and t = 275.6°, the steam turbine can run in a steady state. Because it is a large and heavy equipment, it must be thermally insulated to prevent heat loss to the environment.

Compounding refers to the process of arranging turbine blades in multiple stages in series. This results in a significant increase in the turbine’s efficiency even at low speeds.

Some Useful Questions related to Steam Turbines

1). How Do the Turbine’s Blades Function?

The blades of a turbine are intended to manage the speed, direction, and pressure of steam as it flows through the turbine. For large-scale turbines, dozens of blades are often linked to the rotor in separate sets. Each set of blades contributes to the extraction of energy from the steam while also maintaining ideal pressure levels.

Because of this multi-stage method, the turbine blades reduce the pressure of the steam in extremely modest increments throughout each stage. This, in turn, lessens the forces on them and considerably enhances the turbine’s overall output.

2). How is much energy captured from steam?

Water usually boils at 100°C. At that point, the molecules expand and become vaporised water—steam. Steam provides remarkable efficiency for energy output by capturing the energy inherent in rapidly expanding molecules.