What is a Current Transformer?

A current transformer, often known as a CT, is a type of electrical instrument transformer that is used to step down high currents in electrical circuits to a lower current that can be measured for the purposes of current protection and measurement.

A primary winding, a core, and a secondary winding are the components of a current transformer. However, some transformers, especially current transformers, utilize an air core. The characteristics of a “current” transformer comparison to a “voltage” transformer will vary despite the fact that the fundamental physical principles are the same due to various application needs. A correct ratio between the currents in its primary & secondary circuits must be maintained by a current transformer across a certain range.

Testing of Current Transformer

Current transformers (CTs) are important to power system monitoring and protection. Specific instrument transformers convert high primary currents into lower secondary currents for use with meters, relays, control devices, and other instruments.

CTs enable precise power system monitoring and protection by properly transforming & scaling current readings.

Instrument transformer testing is often considered unimportant. Current transformers used for metering must be accurate to ensure proper billing, while those used for protection must react quickly and accurately to faults.

Testing before service reduces risks like mixing up connections or confusing instrument transformers utilized for metering & protection. Additionally, CT electrical changes caused by ageing insulation can be detected and rectified early.

Current transformers & their devices must be inspected and calibrated regularly for these and other reasons.

CTs should undergo six electrical tests to ensure accuracy and service reliability:

- Insulation Resistance Test

- Winding Resistance Test ( @ 75’C )

- Polarity Test

- Ratio Test

- Excitation (Saturation) Test

- Burden Test

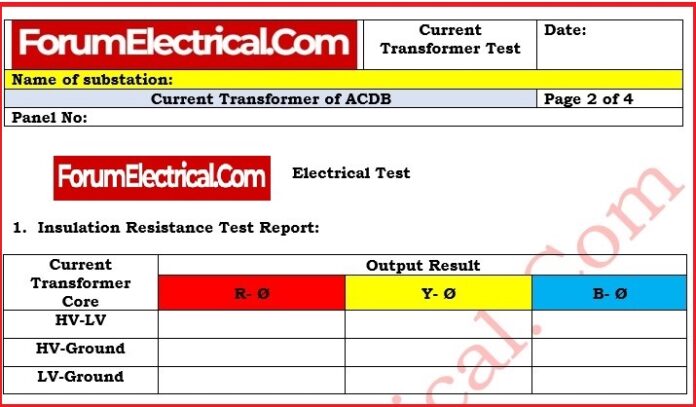

1). Insulation Resistance Test

An insulation tester is used to measure the insulation resistance at a voltage of one thousand volts direct current (1000 VDC) for a maximum of ten seconds per core or line. The core insulation is measured against ground, and then each core is measured against every other core in the transformer. In order to perform this, the secondary grounding that is on the cores of the transformer must be removed.

Insulation testing on the CT’S – current transformers are typically carried out at a voltage of one thousand volts direct current. Connecting H1 and H2 together will create a short in the primary winding of the CT that will be tested. Next, create a short in the CT’s secondary winding that will be tested by connecting X1 to X2-X5 together. Take away the neutral ground, and separate the CT of any burdens that are associated with it.

2). Winding Resistance Test ( @ 75’C )

The winding resistance of a current transformer can be calculated by dividing voltage drop across the winding, which is determined using a dc millivoltmeter, by the dc current that is passed through the winding. After the winding resistance test is finished, the CT needs to be demagnetized so that it can be used.

When determining the actual condition, status, and level of accuracy of a CT, one of the most important measurements to take is the DC winding resistance test. The winding resistance of a CT will fluctuate with time based on the age of the specimen, how it is used, the external conditions, and the loading effect.

3). Polarity Test

The polarity of a CT is established by two factors: the direction (clockwise or counterclockwise) in which the coils are twisted around the transformer core, and the manner in which the leads are taken out of the CT casing.

The polarity of a CT is defined by the winding direction of coils around transformer core (clockwise or anticlockwise) and the configuration of the leads within the CT casing. All current transformers are normally subtractive polarity; therefore, the following names should be used to clearly identify the direction of current flow:

H1- Primary current, line facing direction &

H2- Primary current, load facing direction

X1 – Secondary Current

Polarity marks on a CT reflect the relative instant directions of the currents. The polarity test ensures that the expected direction of secondary CT current is consistent with the specified direction of primary current (incoming).

When installing & connecting a current transformer to a power metering and protection relay, appropriate polarity must be observed. At the same time that the primary current enters the primary terminal, the secondary current should exit the similarly indicated secondary terminal.

A CT under test is assumed to have correct polarity if the instantaneous current direction for primary & secondary currents is opposite.

CT polarity is essential when using CTs in single-phase (or) three-phase applications.

Most modern CT test equipment can perform the ratio test automatically with a simple test lead configuration and will indicate if the polarity is proper or incorrect.

CT polarity is manually confirmed with a 9V battery and an analogue voltmeter using the following CT polarity test procedure:

CT Polarity Test Procedure

All power sources must be disconnected prior to executing the test. Then, connect the analog voltmeter to secondary terminal of the CT being tested. The meter’s positive terminal must be connected to the CT’s terminal X1, and the negative terminal to X2.

Pass a wire through the high side of the CT window and quickly make contact by connecting positive end of 9 V battery to H1 side and negative end to H2 side. Continuous contact should be avoided because it can cause a short circuit in the battery.

When the polarity is proper, the brief contact causes a small deflection of analog meter in positive direction. A negative deflection shows that the current transformer’s polarity has been flipped. In this situation, switch the terminals X1 & X2, and then run the test.

While connecting CTs to ammeters & voltmeters, the polarity becomes unimportant. Polarity is only relevant when connecting CTs to devices like

- Wattmeter,

- Watt-hour meters,

- Varmeters, and

- Induction-type relays.

To maintain polarity, H1 side of the CT must face the power source, while the X1 secondary terminal serves as the polarity connection.

4). Ratio Test

The CT ratio is the relationship between primary current input and secondary current output at the full load.

If the primary current varies, the secondary current output will change simultaneously.

Unlike voltage or power transformers, current transformers have only one or a smaller number of turns as its primary winding. This primary winding can be a single flat turn, a coil of heavy-duty wire wrapped around the core, or simply a conductor or bus bar inserted through a central hole.

The ratio test is used to ensure that the CT’s ratio matches the stated values and that the ratio remains consistent through different taps in a multi-tap CT.

The turn ratio is identical to the voltage ratio of potential transformers, and it can be represented as follows:

N2/N1=V2/V1

Where,

N2 – Number of turns in Secondary Winding

N1 – Number of turns in Primary Winding

V2 – Voltage in Secondary Winding

V1 – Voltage in Primary Winding

Ratio tests are carried out by supplying an appropriate voltage (below saturation) to the secondary of the CT under test meanwhile measuring the primary side voltage to determine the turns ratio using the calculation above.

Important Note: When conducting a CT ratio test, take precautions and do not supply a voltage high enough to cause transformer to saturate. Applying a saturated voltage can result in inaccurate measurements.

Ex: When 600A pass through the primary, a 600:5 CT produces 5 A of secondary current.

If primary current changes, secondary current output changes. 300 amps through a 600A primary produces 2.5A of secondary current.

Unlike voltage or power transformers, current transformers have one or few turns in their primary winding. A single flat turn, a coil of heavy-duty wire wrapped around the core, or a conductor or bus bar through a central hole can be used for this primary winding.

5). Excitation (Saturation) Test

The magnetic path in a “saturated” CT short circuit the transmission line. The CT’s magnetic field is created by redirecting most of the primary winding’s energy away from secondary winding.

The rated knee point of a current transformer is determined by saturation testing against IEEE or IEC standards, at which time it can no longer output current in the proportion to its prescribed ratio.

Excitation testing begin by supplying an AC voltage to the CT’s secondary winding and increasing it in increments until saturation. A moderate voltage increase causes a significant current increase, revealing the “Knee” point.

De-magnetize the CT by gradually decreasing the test voltage to zero. The test results are analysed using a logarithmic graph and taken from the transition time between the normal operation & the saturation.

When a CT is “saturated,” the magnetic path within it acts as a short circuit in transmission line. This enables the majority of the energy supplied by primary winding to be redirected from the secondary winding and used to generate a magnetic field within the CT.

Saturation testing on a current transformer establishes the rated knee point in accordance with IEEE C57.13 or IEC 61869-2 standards. This knee point represents the moment at which the transformer can no longer generate current in accordance to the prescribed ratio.

Excitation tests involve introducing an AC voltage to the CT’s secondary winding and gradually increasing the voltage until it reaches saturation. The “knee” point is found by observing a tiny voltage increase that causes a significant surge in current.

The test voltage decreases over time to zero in order to de-magnetize the CT.

The excitation curve surrounding the locations where current increases in response to a slight increase in voltage is critical for comparing curves to published curves or comparable CT curves. The excitation test results must be compared to available manufacturer data or previous recordings to identify any variations.

The IEEE C57.13 defines saturation as “the point where the tangent is at 45° to the secondary exciting amperes”. Also referred to as “knee” point.

This test ensures that the CT has the correct accuracy rating, that there are no shorted turns, and that there are no short circuits in the CT’s primary or secondary windings.

6). Burden Test

The maximum load (measured in VA) that may be placed on the CT secondary is referred to as the burden test for CT. The weight of the responsibility can be stated in two different ways. It is possible to express the load as the overall impedance of the circuit measured in ohms, the total volt-amperes (VA), and the power factor at a certain value of current, voltage, or frequency.