- What is an ACSR Conductor?

- ACSR Conductor Design

- Inside and Outside Design of ACSR Conductor

- Key Functions of an ACSR Conductor

- ACSR Conductor Sizing

- ACSR Conductor Installation

- ACSR Conductor Maintenance

- ACSR Conductors Performance in Extreme Weather

- Types of ACSR Conductor

- Properties of ACSR Conductor

- Advantages of ACSR Conductor

- Disadvantages of ACSR Conductor

- Applications of ACSR Conductor

- In Summary

- Frequently Asked Questions (FAQs)

ACSR – Aluminium Conductor Steel Reinforced

ACSR refers to a stranded conductor with a number of aluminum wire layers on a stimulated steel wire core.

The steel wire core is just a single wire that varies in size.

These are accessible in various galvanizations, including class A, B, and C, to protect against corrosion.

In this type of conductor, the amount of aluminum and steel used depends on the current-carrying capacity and mechanical strength required for the application. These conductors can be identified based on characteristics such as

- Dependability,

- Economy,

- Weight ratio, and

- Positive strength.

This post provides an overview of the features of an ACSR conductor is, the many types, and how they work.

What is an ACSR Conductor?

ACSR is a high-capacity stranded conductor that is typically used in overhead power lines.

The ACSR conductor structure can be done as follows:

- The outside of the conductor can be built of pure aluminum material, while

- The inside of the conductor can be formed of steel material, which provides extra strength to sustain the weight of the conductor.

Steel has more strength than aluminum, allowing mechanical force to be applied to the conductor.

Galvanizing or coating the steel employed in the conductor can extend its service life. So that corrosion of the material may be avoided. The steel and aluminium diameters can be adjusted depending on the kind of ACSR conductor used.

ACSR Conductor Design

Inside and Outside Design of ACSR Conductor

Outer Perspective: ACSR conductors resemble perfectly crafted cakes. They feature layers of aluminum wires wrapped neatly on a strong steel core, much like icing on a cake. This aluminum coating allows the conductor to perform more efficiently while also making it lighter, making it easier to install & maintain.

Inner Perspective: When we look inside, the steel core resembles the heart of the ACSR conductors. It provides them the strength required to be installed overhead. This inner component not only strengthens the conductor but also allows it to maintain its shape under varying weather conditions.

To top it all off, the exterior aluminium coating is sometimes given additional treatments that make it more rust resistant. This provides another layer of strength to conductor design. It’s like applying a protective coating to keep the conductor safe & long-lasting.

Key Functions of an ACSR Conductor

The essential functions and characteristics that contribute to ACSR conductors’ dependability and flexibility are:

- High Conductivity

- Durability

- Flexibility

- Temperature Resilience

- Weather/Corrosion Resistance

High Conductivity

To reduce power losses while transmission over long distances, the aluminum alloy utilized in ACSR is extremely conductive. Comparatively speaking, aluminum is much lighter and less expensive than copper while having a conductivity of about 60%.

Durability

The steel core provides ACSR with exceptional mechanical reinforcement and strength. It can withstand strikes from debris, ice, and strong winds with consistency. Aluminum is significantly weaker than steel in terms of tensile strength.

Flexibility

ACSR cables are stranded and can be bent, twisted, & coiled during installation since each individually wrapped aluminum and steel wire is part of the cable. As compared to solid conductors, it is far more flexible.

Temperature Resilience

The steel and aluminum used in ACSR products do not lose their strength or integrity at temperatures as high as 150°C or as low as -50°C. Ideal for every kind of weather.

Weather/Corrosion Resistance

When aluminum is exposed to air, it creates an outer layer of oxidation. This keeps corrosion from damaging the conductor. Also improving weather ability is galvanized steel. If necessary, there are specific ACSR coatings available.

To create a single, high-performance cable, ACSR conductors effectively combine the greatest qualities of steel and aluminum.

It is applicable for overhead installations, steel provides mechanical toughness and excellent conductivity, while aluminum offers excellent current capacity.

IEC 61089: Round wire concentric lay overhead electrical stranded cables. This standard specifies round wire concentric lay stranded conductors, including ACSR, utilized in overhead electrical lines.

ACSR Conductor Sizing

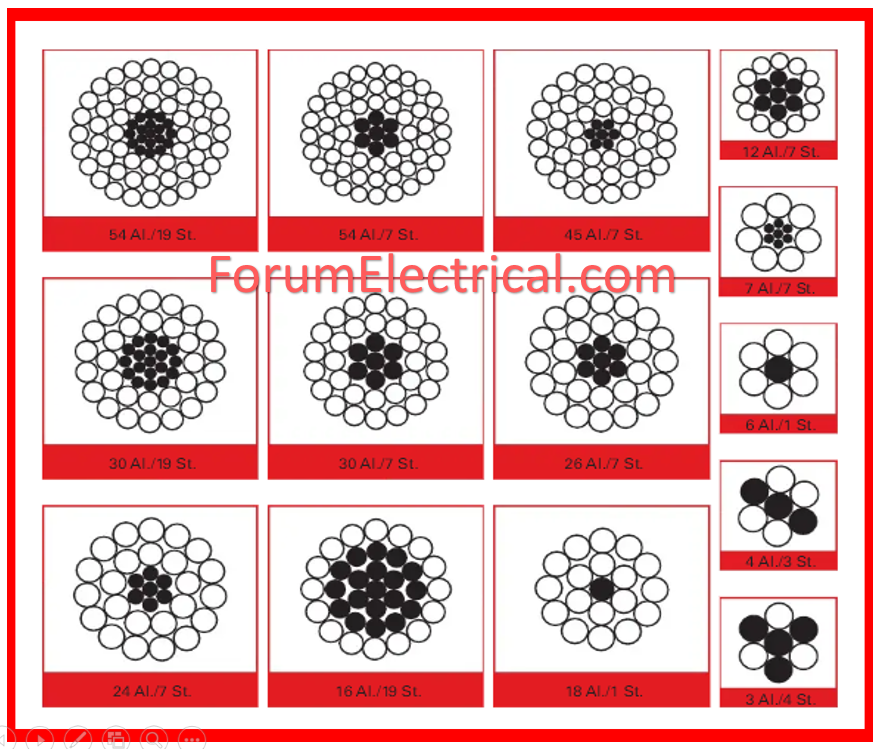

ACSR conductors are available in a wide range of sizes, including single or several center steel wires, and you can choose from any of these options.

A significant quantity of aluminum strand, in general. In spite of the fact that there are some types of conductors that are available, aluminum strands are significantly fewer in number than steel strands.

The stranding associated with an ACSR can be used to identify the component of the ACSR.

- 6Al/1St. ACSR

- 18Al/1St.ACSR

- 36Al/1St.ACSR

- 12Al/7St.ACSR

- 26Al/7St.ACSR

- 45Al/7St.ACSR

- 54Al/7St.ACSR

- 54Al/7St.ACSR

- Dog ACSR ( 33/66KV, 300A)

- Panther ACSR (66/132KV, 480A)

- Zebra ACSR ( 220KV, 735 A)

- Moose ACSR ( 220/400KV, 800 A)

If a conductor has six aluminum strands and a single layer galvanized steel core, it is known as 6Al/1St. ACSR.

Note: Different codenames are employed to prevent numerical value confusion.

ACSR Conductor Installation

- Proper handling and storage techniques protect the conductor’s integrity & durability.

- Accurate sag estimates are essential for efficient power transmission & avoiding sag-related difficulties.

- The selection & installation of the supporting hardware have a significant impact on the conductor’s performance.

- Proper grounding is required for safety and to retain the conductor’s electrical properties.

ACSR Conductor Maintenance

- Regular cleaning avoids the accumulation of impurities that could impair the conductor’s performance.

- Maintaining the conductor’s temperature helps in the identification of possible problems and assures peak performance.

- Routine visual inspections assist in detecting visible symptoms of wear, damage, (or) corrosion.

- Regular tension adjustments help to maintain the mechanical integrity of the conductor.

- Quick diagnosis and resolution of frequent problems ensures continuous power transmission.

ACSR Conductors Performance in Extreme Weather

- Proper precautions to reduce the effect of high temperatures on the ACSR conductors.

- Solutions for sustaining ACSR functioning in freezing temperatures.

- Measures to mitigate the impact of heavy rain & storms.

- Techniques for overcoming problems in coastal (or) corrosive settings.

Types of ACSR Conductor

Copper conductors were utilized in energy transmission for many years, but AI conductors are currently replacing them for a variety of reasons, including lower cost than copper, larger diameter, and so on.

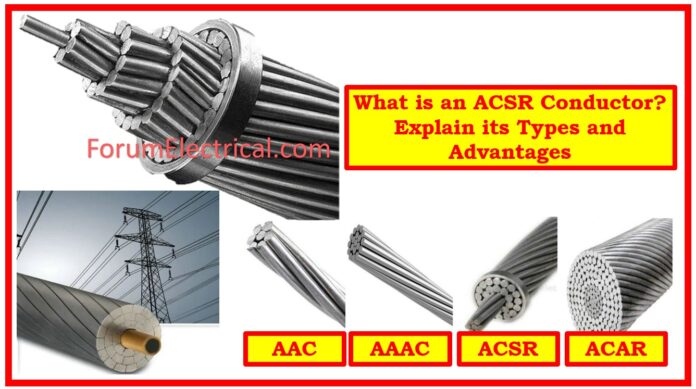

There are many types of ACSR conductors available, including the following.

- All Aluminium Conductor (AAC)

- Aluminium Conductor Aluminium Reinforce (ACAR)

- All Aluminium Alloy Conductors (AAAC)

- Aluminium Conductor Steel Reinforced (ACSR)

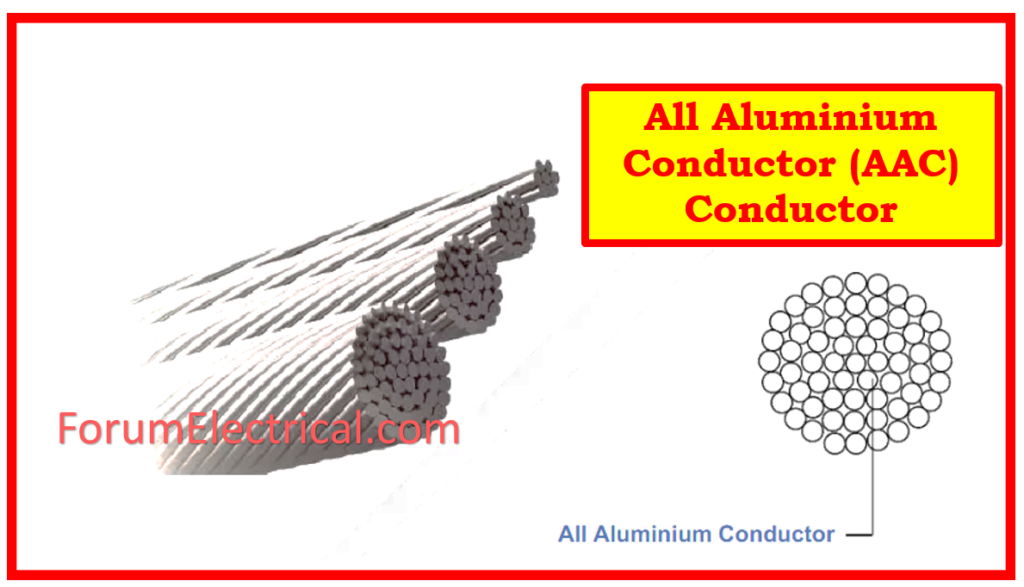

All Aluminium Conductor (AAC) Conductor

This conductor has lower strength and more sag per span length than any other type. Thus, it is utilized at the distribution system.

The conductivity of this conductor is slightly higher at the distribution level. The cost of both AAC and ACSR conductors is same.

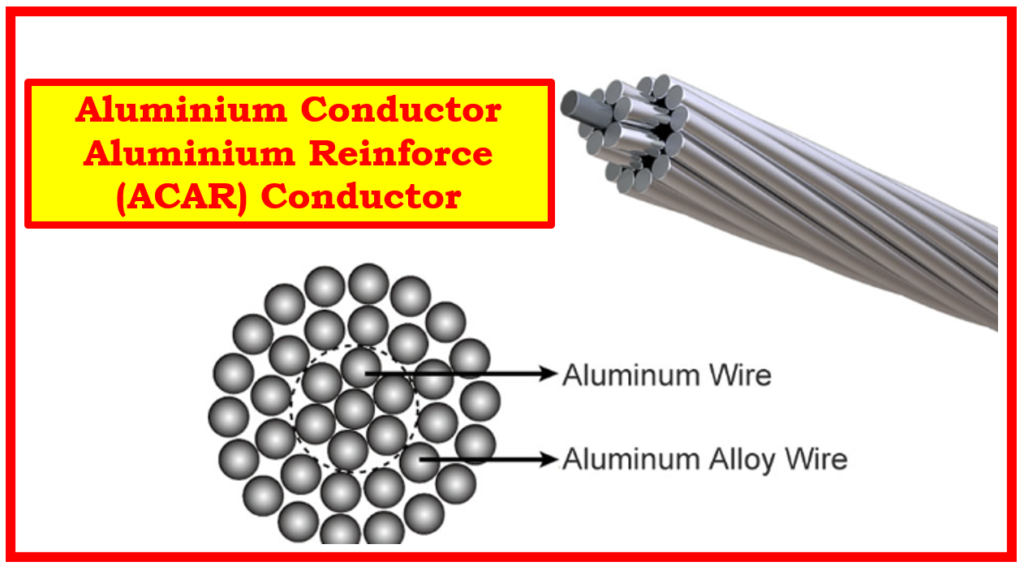

Aluminium Conductor Aluminium Reinforce (ACAR) Conductor

Aluminium Conductor Aluminium Reinforce (ACAR) combines aluminum alloy strands to provide a transmission conductor with good electrical and mechanical balance qualities.

These aluminum strands are encased in aluminum alloy wires. The conductor’s core contains the number of strands.

The fundamental advantage of this conductor is that every strand are identical, allowing for conductor design with the finest electrical and mechanical properties.

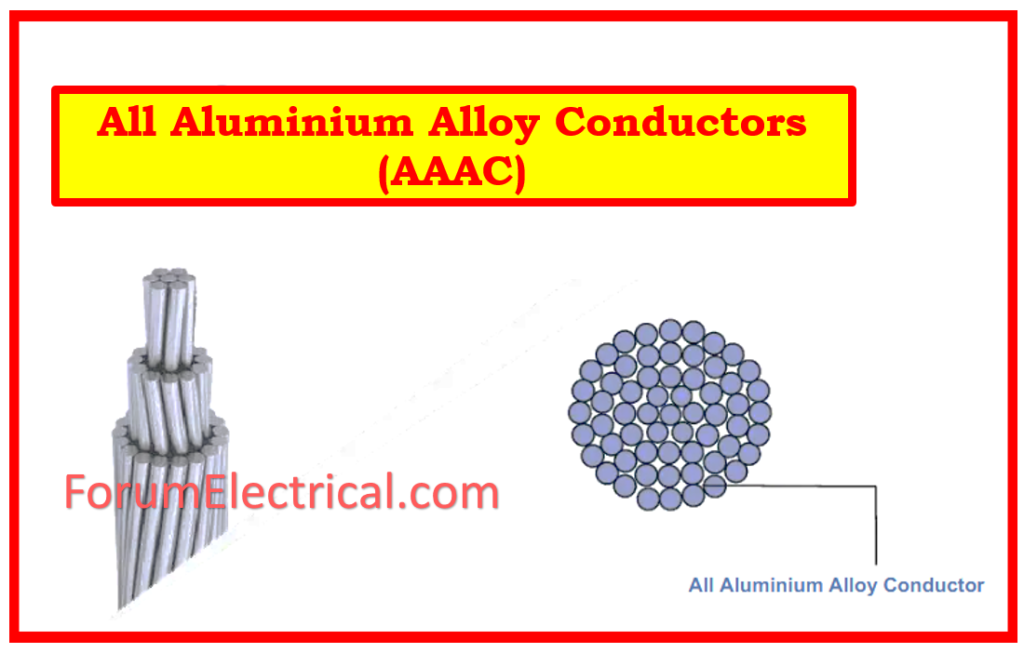

All Aluminum Alloy Conductors (AAAC) Conductor

The AAAC conductor structure is equivalent to AAC except for the alloy. This conductor has the same strength as the ACSR type, but it weighs less because there is no steel.

The presence of alloy production will make this conductor more expensive. AAAC is utilized for longer spans due to its higher tensile strength as when compared with AAC.

So it is used at the distribution level, which is a river crossing.

Compared to AAC, this conductor has little sag. AAAC conductors are light in weight, making them suitable for transmission and sub-transmission applications where a light support structure is required, such as wetlands and mountains.

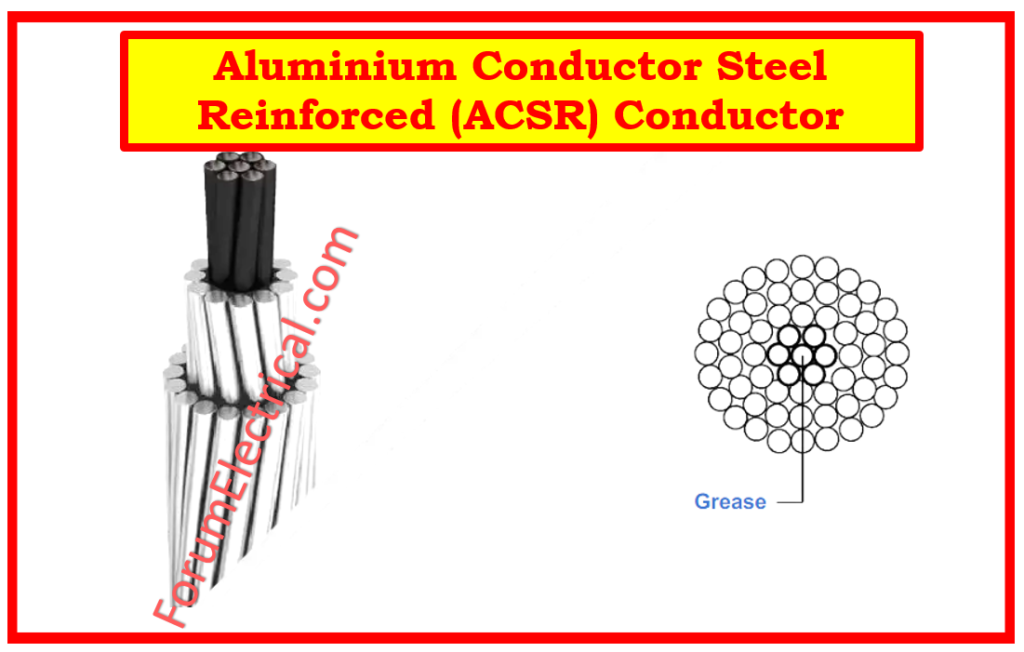

Aluminium Conductor Steel Reinforced (ACSR) Conductor

Aluminium Conductor Steel Reinforced (ACSR) conductors contain steel material inside.

The high strength ACSR conductors are suitable for overhead earth wires, installations with extra-long spans, and river crossings.

These are made with varying tensile strengths. The large diameter allows for a much higher radiance limit.

ASTM B232/B232M is the Standard Specification for Concentric-Lay-Stranded Aluminum Conductors Reinforced with Coated Steel. This standard defines the specifications for ACSR conductors, such as construction, materials, dimensions, electrical properties, & testing procedures.

Properties of ACSR Conductor

The ACSR conductor’s features include the following:

- Skin Effect

- Proximity Effect

- Hysteresis Loss

Skin Effect

- The skin effect causes the conductor’s cross-sectional area to decrease as current passes through it.

- For AC, the majority of the current flow can occur between the exterior and the depth of the skin. It is primarily determined by the frequency with which current flows and the qualities of the conductor.

- Because of the inverse relationship between the conductor’s cross-sectional area and resistance, this lower area will increase resistance.

- The skin effect improves conductor design by causing current to flow in the low-resistivity aluminum path near the conductor’s outside.

- To illustrate the effect of this phenomenon, the ASTM, or American Society for Testing and Materials standard, includes steel core conductivity while testing the conductor’s resistance in both AC and DC modes.

Proximity Effect

- Once AC current runs across the conductors, the current flow in each conductor can be driven to smaller regions, which is known as the proximity effect.

- This phenomenon is caused by a changing magnetic field, which powers the electric current flow in a conductor via electromagnetic induction.

- When AC current flows through an isolated conductor, it generates an alternating magnetic field in the surrounding area.

- This magnetic field induces eddy currents within consecutive conductors, altering the overall current distribution.

Hysteresis Loss

- The atomic dipoles inside the steel core create the majority of hysteresis losses in the ACSR conductor.

- These losses are undesirable, but they can be decreased by using aluminum layers that are evenly distributed throughout the conductor.

- The hysteresis loss is negligible in this conductor, regardless of the number of aluminum layers.

- For these conductors with an odd number of aluminium layers, a magnetization characteristic is used to correctly determine the AC resistance.

- Because of the large hysteresis losses in the steel and related core heating, the odd-layer design will have a lower capacity rating than the even-layer design.

- All typical ACSR conductors typically small than Partridge because they contain only one layer due to their small diameters, hence hysteresis loss cannot be prevented.

The specifications for coated steel reinforced (ACSR) concentric-lay stranded aluminum conductors are specified in ANSI C29.7. The ACSR conductors utilized in American overhead electrical wires are specified by this ANSI standard.

Advantages of ACSR Conductor

- ACSR conductor structure is planar.

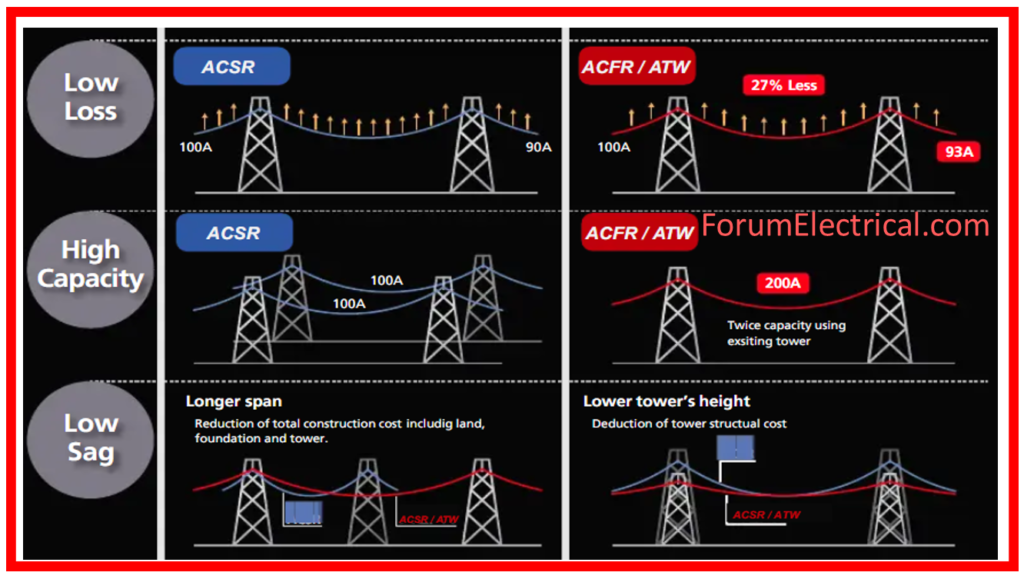

- The capacity for transmission is high.

- These cables are recognized by their exceptional tensile power.

- Excellent performance.

- These have lengthy lifespans and provide high flexibility.

Disadvantages of ACSR Conductor

- Though corrosion-resistant, aluminum can corrode over time, particularly in severe conditions. This can shorten conductor life and raise maintenance expenses.

- ACSR conductors cost less than all-copper conductors but more than all-aluminum ones.

- Installation and maintenance of ACSR conductors need experienced labor and specialized equipment, which can increase cost and time.

- Damaged ACSR conductor sections can be difficult to repair (or) replace without disturbing the system.

- ACSR conductors are valuable and can be stolen for scrap, disrupting electricity transmission and distribution.

- ACSR conductors are less flexible than conventional conductors, making them unsuitable for particular applications.

Applications of ACSR Conductor

- ACSR is commonly utilized in the building of overhead lines for power transmission because of its strength & efficiency.

- ACSR is appropriate for distributing power in both rural & urban locations, meeting a wide range of energy requirements.

- Due to its sturdy structure, the conductor is appropriate for these applications.

- ACSR utilized in wide range of industries where dependable power transmission is required.

- Overhead power transmission lines up to 500 kV.

- Electrical distribution systems of up to 34 kV.

- Feeders connect substations, switchyards, and transformers.

- Bridges over rivers, valleys, and highways.

- Public electricity distribution poles.

In Summary

Systems for the distribution and transmission of overhead power must include ACSR conductors. They are dependable and effective in a range of environmental conditions due to their exceptional

- Electrical conductivity,

- High tensile strength, and

- Other significant characteristics

- Low weight,

- Weather resistance, and

- Economic efficiency.

With regard to power transmission, we hope that this overview has brought on the many kinds of ACSR cables & their many advantages.

This concludes our overview of the ACSR conductor, which consists of an aluminum strand enclosing a solid steel core that is otherwise stranded.

This conductor has one or more layers of aluminum wire encased in a very strong steel core. These can be found in a wide range of steels with carbon contents ranging from 0.5% to 0.85%.

Frequently Asked Questions (FAQs)

1). What is an ACSR conductor used for?

ACSR is a type of stranded conductor that is utilized in the overhead power transmission lines.

2). What type of wire is ACSR?

ACSR is a stranded conductor consisting of a central steel core surrounding by one or more layers of aluminum wire.

3). What are the physical properties of ACSR?

ACSR has great tensile strength, excellent conductivity, and little sag.

4). How can the steel in the ACSR conductor be uncharged?

Steel is utilized to give the necessary mechanical strength in the conductor. Aluminum has substantially higher conductivity than steel (around 20-21 times). And as the self-inductance of steel strands is likewise very low, any leakage current flow because of minimal Inductance is also insignificant. Current always flows in a highly conductive path. As a result, the vast majority of the stream passes through the alüminium. Negative current will pass through the steel.

5). What is ACSR conductor?

ACSR stands for Aluminium Conductor Steel Reinforced Cable. It is a type of high-tension wire utilized for overhead power transmission & distribution systems.