Table of Contents

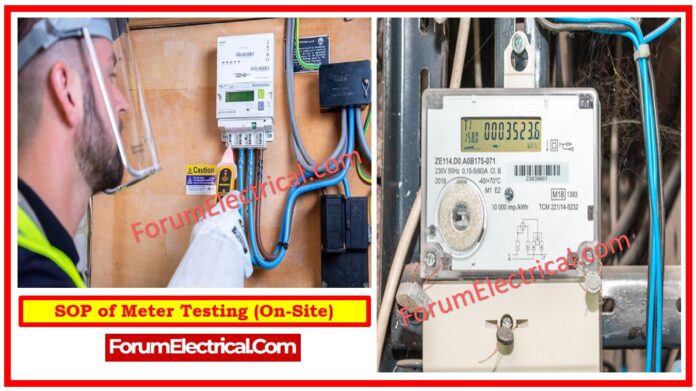

The periodic testing of consumer metering installations to confirm their healthiness should be carried out meticulously in accordance with this process and IS 15707.

Planning

Metering installations must be tested on a regular basis, determined by contract demand.

| Contract Demand | Frequency |

| Up to 1 MVA | Annually |

| Above 1 MVA & up to 3MVA | 6 Monthly |

| 3 MVA & Above | 3 Monthly |

Plan the timetable such that the time between two testing dates does not exceed the limits listed below:

| Frequency | Duration between 2 tests | Tolerance |

| Annual | 1 year | 2 Months |

| 6 Month | 6 Month | 1 Month |

| Quarterly | 4 Month | + 15 days |

Installation keys must be kept with the testing team.

The planned testing visit should astonish the consumer.

Instrumentation

Testing equipment should be accurate, calibrated from a laboratory, and well maintained.

On-site testing requires the minimal equipment and accessories listed below:

- Electronic reference standard meter with clamp (class 0.2 or above)

- Use a clamp-on ammeter of Class 1 (or) above

- Multimeter Class 1 (or) higher

- MRI/laptop with wires

- Toolkit

- Scientific calculator

- Metering Installation Testing Formats

- Seals

Verifying Metering System Accuracy

- Perform seal verification of kiosk & meter before testing.

- If the seals are tampered with, testing should only start with an O&M official and customer representative present.

- Consider connecting the ERS meter to an auxiliary power supply to reduce the load on the PT circuit.

- Connect PT circuits by connecting the neutral first, then all phases.

- CT must be clamped to the current circuit after connecting to ERS. CT direction should be checked when connecting clamps.

- The clamp CT jaws must be clean (ideally once a month with anti-corrosion solutions) and closed tightly to avoid recording errors.

- ERS meters should be set to match their CT and PT ratios. So ERS and meters have the same voltage and current units.

- The vector diagram must confirm MTC classification. ERS memory should hold the same.

- Record meter and ERS current and voltages simultaneously for confirmation. Record voltage and current THD %. Record the supply phase sequence.

- If instantaneous PF is high, consumers should be instructed to turn off capacitor units to lower it.

- Testing starts when load current exceeds 5% of Ib & PF is within 0.5 lag to Unity. Consumers should raise load for test duration if load is low, or testing should be delayed.

- Record mistakes of the meter under test in scanner mode. Record at least 5 errors. The number of scanner test pulses depends on load current, but one error should take at least 40 seconds.

- Note cumulative & zone-wise energy readings and confirm total zone energies with cumulative reading.

- The registration test should last 30 minutes. Initial and final readings should be taken from high-resolution display or MRI calibration mode.

- Start the test by recording the initial RD & record periodic values over time.

- Record sample readings of HT & LT current & voltage during the test.

- A sufficient number of samples must account for load changes.

- KVA apparent power on ERS must also be recorded.

- Calculate registration error using ERS standard energy and meter units.

- Calculate PF for test duration using KVARH and KWH differences.

- Calculate average KVA from HT & LT current & voltage samples, and confirm with MD for test time.

- After the test, get all meter data by MRI or laptop.

Test Interpretation

The IS 15707 error limits are as follows:

| Accuracy Class | Test points | PF | Overall uncertainty of Meter Test | Maximum Permissible |

| Equipment | Error | |||

| % | % | |||

| 1 | 10% Ib to Imax | 1.0 & 0.5 Lag | ±0.4 | ±2.5 |

| 1.0 S | 5% Ib to Imax | 1.0 & 0.5 Lag | ±0.3 | ±2.0 |

| 0.5 S | 5% Ib to Imax | 1.0 & 0.5 Lag | ±0.2 | ±1.0 |

- If meter errors (scanner and registration) surpass the above limits, the meter may be replaced. The same meter must be checked in a laboratory in front of the consumer to confirm the inaccuracy. If the inaccuracy is significant, the necessary assessment must be communicated.

- If meter errors are within limits, but there is a significant discrepancy in HT/LT KVA and units, it may be necessary to test CT and PT to determine if the CT is saturated or if the errors are out of accuracy class.

- If the RTC of a meter drifts by more than 5 minutes for 0.5s or 2 minutes for 0.2S class meters, it must be changed using an MRI or laptop.

- Analyze meter data for tamper occurrences.

- Preserve copies of meter tamper data, instantaneous values, and vector diagram from ERS in the test report for future reference.

Installation Checkup

- Inspect the complete metering installation to ensure its health.

- Provide a dedicated access route from the public road for testing and vigilance teams to reach the installation quickly.

- To avoid illegal access, there should be no switches or disconnectors before the metering kiosk.

- Incoming cable should be routed through a trench with a grill. Cable must be visible up to the metering kiosk.

- Ensure good maintenance of the metering shed and kiosk to prevent exposure to rain, dust, and moisture.

- The metering room should have appropriate ventilation, cleanliness, and space from all sides of the kiosk.

- The metering room should include an auxiliary supply for the testing equipment, lights, and fans.

- Restrict access to the metering room to authorized individuals only.

- Ensure earthing strips are correctly attached and free of corrosion. The earthing strips must not overlap one another.

- Ensure the secondary wire from CT/PT to meter is free of joints and has adequate ferrules.

- Transformer capacity must be the same as a CD.

- Provide LT metering for 0.5S class, ideally with a multifunction meter.

- Ensure supply voltage level matches CD as per SOP. If there is a deviation, the bill should be reviewed to ensure that the voltage surcharge is applied correctly.

- Check the energy bill for accurate use patterns, tariffs, and additional costs such as express feeder charges.