Power Cable Loss

When current flows, conductor resistance heats up, causing cable power losses (or) power drops. The cable losses are frequently referred to as KW losses or I2R losses. “Insertion Loss” is another term for cable loss. When designing a system, cable loss should be considered.

Power losses are mainly in two forms, they are

- Resistive loss and

- Reactive loss

Resistive Loss

Resistive losses are directly proportional to square of the current, they can be reduced by utilizing high voltages and low current.

Reactive Loss

Capacitance between conductors is the cause of reactive losses. Both of these are proportional to the real capacitance and frequency. By keeping the conductors as far apart as feasible and isolating them from one another with a low permittivity medium (air), the capacitance is reduced. These factors lead to pylons.

Ohmic Conductor Losses

The losses brought on by the ohmic characteristic of the material are known as ohmic losses. The circuit’s voltage drop is represented by ohmic losses. The voltage drop along a circuit is proportional to the amount of current flowing through it, per Ohm’s law. Ohmic conductor losses are impacted by the material.

The following formula expressed for three phases as follows:

Power losses = (3 x I²R) /1000

Where,

kW- Power,

I – Current (in amps) and

R – Average Conductor Resistance (in ohms).

The following equation can be used for single phase & DC

Power losses =( 2x I²R x L)

Where,

kW- Power,

I – Current (in amps) and

R – Average Conductor Resistance (in ohms).

L – Length of the Cable

Power Losses due to skin effect

The skin effect refers to the concentration of AC current close to the surface conductor. The effective of a cross-sectional area for current flow is decreased by the skin effect.

Skin effects can increase power losses and conductor heating, reducing transmission line efficiency and reliability. Transmission line impedance and voltage loss increase, affecting signal quality & power transmission.

Compared to solid conductors, the skin effect is less prominent with stranded conductors.It can be decreased by reducing the wire’s diameter.

Special conductor designs (segmental conductors) can be used to reduce them. For cross sections between 500 mm2 and 2000 mm2, the losses may account for up to 8% to 17% of the conductor’s ohmic losses.

Power Losses arising from the proximity effect

These are turned on by magnetic fields, which in turn force parallel conductors to be placed closely together. Even for large conductor cross-sections, the effect can be minimized to 10% of ohmic conductor losses if the cables are spaced out widely apart.

Sheath Losses

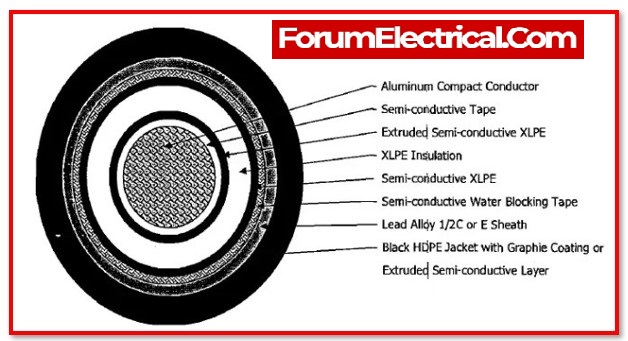

As a result of the induced e.m.f generated by the flux linkage with lead sheath, a cable experiences sheath loss, which is a power loss in the lead sheath.

Eddy currents and generated sheath currents are responsible for power loss in the sheath or screen.

The electrical properties and current rating of single-core paper-insulated lead-covered and serviced power cables used on AC systems are affected by the lead sheath surrounding each insulated conductor.

If the lead sheaths are bonded together or earthed, transformer act between the conductors and the sheaths induces a voltage in the open circuited sheaths, which depends on the flux interlinked with the sheaths and increases with cable interaxial spacing.

The bonding short circuits the induced sheath voltages, causing current to flow along the sheath and heat the cable serving & surrounding ground or air.

Due to the lead sheath circuit’s non-symmetrical magnetic field, eddy currents are generated.

Thus, lead sheath heating losses are

(a). Sheath circuit loss for bonded sheaths and

(b).Sheath eddy loss.

Sheath eddy loss is usually much smaller than sheath circuit loss & can be ignored.

Dielectric Losses

The term “dielectric loss” refers to a power loss that happens in paper insulation (dielectric) of a cable as an outcome of the electric field created by leakage current and, in the case of an AC supply, current reversal. The temperature causes this loss to rise.

It directly affects how a cable functions. At its operational temperature, a given cable has a specified capacity to dissipate heat.

As a result, any increase in the dielectric loss will cause a reduction in the capacity to carry loads. Dielectric losses for cables working up to 33 kV are often insignificant.

All cables experience losses, & these losses eventually decrease a system’s performance. The cable specifications and quality have an impact on how much of a loss occurs.

Losses that occur, and they include:

- Losses due to skin-effects, which predominate at low frequencies

- High frequencies are dominated by dielectric losses

- Return path losses, which are usually insignificant & can be ignored

- Losses resulting from connections to the output nodes (or) the DUT established via connectors, relays, or other devices

How may the cable’s resistance be lowered?

The amount of power lost in the cable depends on the cable’s size, length, and current flow.

As a result, there are three methods to reduce cable resistance:

- Reduce the cable’s total length.

- The conductor size should be increased,

- Reduce the flow of current that flows through the cable.

Minimize cable length

The KW losses in the electrical stability control (ESP) system can be reduced in the long term if the cable length is kept to a minimum.

This has a substantial impact on the cost component involved in the purchase of the cable.

Determine the size of the conductor

The original capital cost of cable will be greater the larger the conductor size that it possesses. Therefore, there are a lot of various factors to take into consideration while buying the cable, including the following:

- What is the current load (in amps) that is expected ?

- When the need increases up to +90%, the present load will be comprising in the future?

Increasing the conductor size helps lower the resistance in the cable, which in turn minimizes the amount of power that is lost. On the other end, as was noted previously, the initial expense cost of the cable will increase proportionally with the conductor size.

Voltage Drop

The size & the conductor length at the bottom hole temperature are the two factors that are used to calculate the voltage drop. In order to determine the correct surface voltage, the voltage drop across the cable needs to be added to the voltage that is listed on the nameplate of the motor.