- Purpose of Cable Trays

- Cable Tray norms as per National Electrical Code (NEC)

- Number of multicore cables in cable tray that are under 2000 volts

- Number of single-conductor cables in the cable tray that are not greater than 2000 volts (NEC-392.12)

- Number of Cables in the Cable Tray that are greater than 2.1 KV

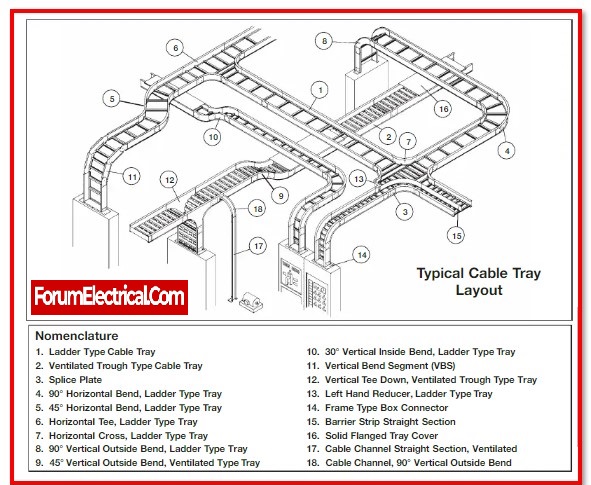

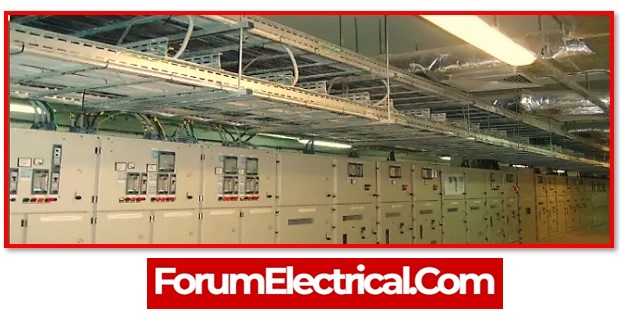

Cable tray systems are an alternative to wire ways & electrical conduit, which entirely protect wires.

Many different types of wire can be accommodated in cable trays, including

- High-voltage power lines.

- Power Distribution Cables

- Control cables

- Telecommunications cables

- Fiber Optical Cables

Purpose of Cable Trays

Cable trays are components of the systems that support the cables and wires that supply electricity and communications.

A cable tray system makes it easier to upgrade, expand, reconfigure, or move networks by supporting and protecting both power & signal wires.

Since most cable tray systems are open, efficient heat dissipation is possible as well as simple replacement and maintenance access. Some cable tray systems are appropriate for under floor use, despite the fact that they are normally suspended from ceilings (or) attached to walls.

Cable Tray norms as per National Electrical Code (NEC)

National Electrical Code (NEC) specifies the capacities of cables rated at 2000 volts or less in cable trays. Single Conductor Cables enable cables of equivalent construction & conductor material to be functioned at varying maximum ampacities based on how the cables are physically placed in ladder (or) ventilated through cable trays.

Number of multicore cables in cable tray that are under 2000 volts

1). 4/0 AWG/Kcmil (120 Sq.mm) Cable (or) Larger Cables

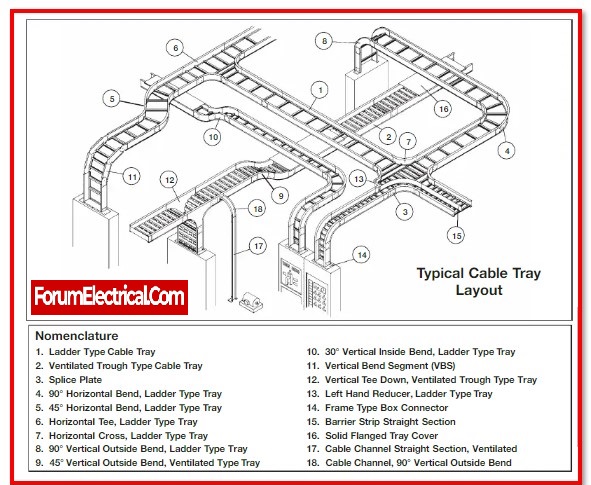

Ladder cable tray: The interior usable width of the tray must be at least as wide as the total of the cables’ individual layer-installed diameters.

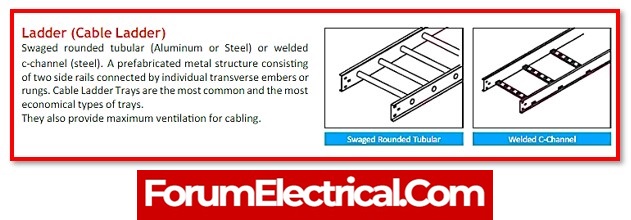

Solid bottom cable tray: The sum of cable diameters must not be greater than 90% of the allotted cable tray width.

2). Cables Smaller than 4/0 AWG/Kcmil (120 Sq.mm)

Ladder cable tray: All cables inserted in the cable tray must possess cross-sectional areas equal to or less than the tray width’s permissible cable area, as shown in the accompanying table.

Solid bottom cable tray: Allowable cable area drops 22%.

| Inside Width of the Cable Tray | Allowable Cable Area square inches(square millimeter) |

| 6 inches(152.5millimeter) | 7 square inches(4516 square millimeter) |

| 9 inches (228.6millimeter) | 10 square inches(6451 square millimeter) |

| 12 inches (304.8millimeter) | 14 square inches(9032 square millimeter) |

| 18 inches(457.2millimeter) | 21 square inches(13548 square millimeter) |

| 24 inches (609.6millimeter) | 28square inches(18064 square millimeter) |

3). Installing cables larger than 4/0 AWG (120 Sq.mm) with cables smaller than 4/0 AWG (120 Sq.mm)

Ladder cable tray: The ladder cable tray must be divided into 2 zones (a barrier or separator is not required, but can be employed if desired) so that No. 4/0 and bigger cables have their own zone, as they will be arranged in a single layer.

Proper cable tray: A simple method for determining the correct cable tray width is to calculate the cable tray widths needed for each of the cable configurations per steps (2) and (3). Then sum the widths to determine the required cable tray width.

4). Multi conductor Control & Signal Cables Only

Ladder cable tray: 50% of the total cable area in a ladder cable tray that only contains control and signal cables can be taken up by cables.

Solid bottom cable tray: The permissible cable space decreased from 50% to 40% when employing a solid bottom cable tray.

Number of single-conductor cables in the cable tray that are not greater than 2000 volts (NEC-392.12)

Single conductor cables that are going to be inserted in the cable tray have to be larger than 1/0 AWG (53.5 Sq. mm), and solid able tray cannot be used for the installation process.

1). Cables with a cross sectional area of 500 square millimeters or larger

The total diameters (Sd) of all the single conductor cables that are going to be installed must not be greater than the width of the cable tray, as shown in the following table.

| Inside the Width of the Cable Tray | Allowable Cable Area square inches (square millimeter) |

| 6 inches (152.5 millimeter) | 6.5 square inches (4194 square millimeter) |

| 9 inches (228.6 millimeter) | 9.15 square inches (6129 square millimeter) |

| 12 inches (304.8 millimeter) | 13 square inches (8387 square millimeter) |

| 18 inches (457.2 millimeter) | 19 square inches (12258 square millimeter) |

| 24 inches (609.6 millimeter) | 26square inches (16774 square millimeter) |

| 30inches(762millimeter) | 32.5square inches (20968 square millimeter) |

| 36 inches (914.5millimeter) | 39square inches (25161square millimeter) |

2). Cables ranging from 250 kcmil (120 square millimeters) to 1000 kcmil (500 square millimeters)

The entire amount of the cross-sectional areas for all of the single conductor cables that are going to be positioned in the cable tray needs to be equal to or less than the permissible cable area for tray width, which may be found in the table that follows.

| Inside the Width of the Cable Tray | Allowable Cable Area square inches (square millimeter) |

| 6 inches (152.5 millimeter) | 6.5 square inches (4194 square millimeter) |

| 9 inches (228.6 millimeter) | 9.15 square inches (6129 square millimeter) |

| 12 inches (304.8 millimeter) | 13 square inches (8387 square millimeter) |

| 18 inches (457.2 millimeter) | 19 square inches (12258 square millimeter) |

| 24 inches (609.6 millimeter) | 26 square inches (16774 square millimeter) |

| 30 inches (762 millimeter) | 32.5 square inches (20968 square millimeter) |

| 36 inches (914.5 millimeter) | 39 square inches (25161 square millimeter) |

3). Cables larger than 1000 Kcmil (500 Sq.mm) installed with cables smaller than 1000 Kcmil (500 Sq.mm)

The entire sum of the cross-sectional areas for all of the single conductor cables that are going to be positioned in the cable tray needs to be equal to or less than the permitted cable area for tray width, which is indicated in the following table:

| Inside Width of the Cable Tray | Allowable Cable Area square inches (square millimeter) |

| 6 inches (152.5 millimeter) | 6.5 square inches (4194 square millimeter) |

| 9 inches (228.6 millimeter) | 9.15 square inches (6129 square millimeter) |

| 12 inches (304.8 millimeter) | 13 square inches (8387 square millimeter) |

| 18 inches (457.2 millimeter) | 19 square inches (12258 square millimeter) |

| 24 inches (609.6 millimeter) | 26 square inches (16774 square millimeter) |

| 30 inches (762 millimeter) | 32.5 square inches (20968 square millimeter) |

| 36 inches (914.5 millimeter) | 39 square inches (25161 square millimeter) |

4). Single-conductor cables ranging from 1/0 (50 sq. mm) to 4/0 (120 sq. mm)

Installing these single conductors requires only one layer.

Analysis: Certain consideration that this method could have complications with Individual conductors for this form of cable tray wiring system should be tied together to prevent those possible problems caused by uneven voltages. If used, the neutral conductor should also be included in the bundle together with all three phase conductors.

Tray width for single-conductor size cables:

- 1/0AWG (50 square millimeter)

- 101520312/0AWG (70square millimeter)

- 91419293/0AWG(9550square millimeter)

- 81317264/0AWG (120square millimeter)

- 8121625/0kcmill (120square millimeter)

- 11182435/0kcmill (185square millimeter)

- 9141950/0kcmill (240square millimeter)

- 7111475/0kcmill(400square millimeter)

- 5810100/0kcmill (500square millimeter)

Number of Cables in the Cable Tray that are greater than 2.1 KV

The total diameter of all cables with a voltage rating of 2001 volts or higher cannot be greater than the width of the cable tray.

1). Minimum Requirements for Barriers (NEC 392.6)

- A barrier is placed between the single-core cables of above and below 600 volts when they are installed in same cable tray. This maintains the cable systems different.

- However, if multi-Core type cables with voltages greater than 600 volts are placed in same cable tray as cables with voltages of 600 volts or less, there is no need for barriers.

- The barriers need to be fabricated from the identical substance as the cable tray, and their height needs to be comparable to that of cable tray.