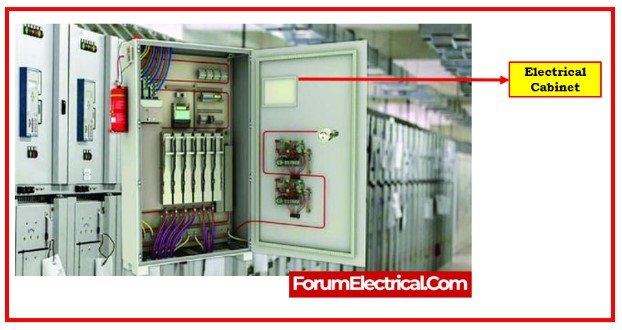

What is an Electrical Cabinet?

An electrical cabinet is a type of protective housing that is utilized for the purpose of maintaining an array of electrical components and equipment. This type of housing is also referred to as an electrical enclosure (or) electrical control enclosure. These cabinets are often constructed out of metal or non-conductive materials like plastic. They are designed to offer a secure & safe environment for electrical & electronic equipment, as well as to protect these electronics from environmental variables such as dust, moisture, heat, and physical damage.

Characteristics of Electrical Cabinet

The following are important characteristics of electrical cabinets:

Protection

The purpose of electrical cabinets is to shield potentially damaging elements of the environment, such as moisture, dust, and even direct human contact, from sensitive electrical equipment. They frequently make use of seals and gaskets in order to produce an airtight and secure enclosure.

Safety

Electrical cabinets offer an additional layer of protection against anyone coming into contact with active electrical components. They frequently have doors that lock and may have been constructed in a way that prevents unwanted entry.

Cooling & Ventilation

Several electrical cabinets are equipped with ventilation systems (or) fans to help remove the heat that is produced by the enclosed equipment. This helps to maintain a temperature within the cabinet that is adequate for working at all times.

Cable Management

In order to better manage & organize electrical wiring, electrical cabinets frequently include plugs or cable glands in addition to cable entry and exit holes for cables.

Mounting

They offer a wide range of mounting alternatives for electrical components, including DIN rails, backplates, and brackets, which are utilized to safely retain the apparatus in place.

Labeling and Documentation

Correct labeling of components and detailed documentation within the cabinet are both helpful in identifying & troubleshooting problems with electrical systems.

Electrical cabinets are frequently utilized in a wide variety of industrial and commercial contexts, including power distribution centers, manufacturing facilities, telecommunications facilities, data centers, as well as control rooms, among other places. The application and the electrical components that are housed within an electrical cabinet both have the potential to influence the specific design & features of the cabinet.

Controlling Electrical Cabinet Problems

When control & power circuits are housed in the same cabinet, be careful of interference.

In simple terms, interactions between the control and power wiring inside within the limits of one electrical cabinet might result in performance abnormalities.

There is a simple step technique for troubleshooting those problems.

Before identifying cabinet wiring, users must be familiar with the current wiring color codes.

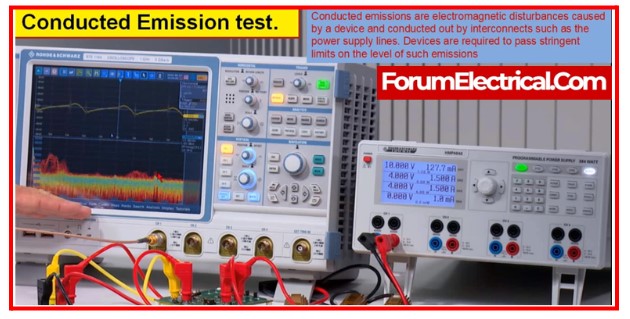

EMI – Electromagnetic Interference

Problem: Internal electromagnetic interference (EMI) from adjacent machinery (or) radio frequency interference can cause sensitive electronic components to malfunction.

Troubleshoot: Separate conduits are used to bring in the low-voltage control wiring and the 480-volt power conductors. In the outdoors, separating these conductors into distinct conduits reduces the possibility of electromagnetic interference (EMI).

Power conductors must be positioned as far from communication and control cables as feasible in order to minimize electromagnetic interference.

Within the cabinet, keep the control and power wires in different wiring trays. If power conductors or control wires must cross for any reason, make sure they do so at a straight angle to lessen the effects of electromagnetic interference (EMI).

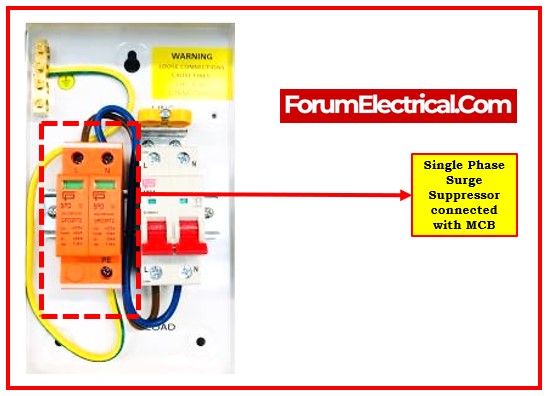

Power Surges and Voltage Spikes

Problem: Sudden power surges (or) voltage spikes can cause components to become damaged, which can ultimately result in the failure of the system.

Troubleshoot: High-quality surge protectors, which are often referred to as suppressors, are the most effective protection against the harm caused by power surges. Ensure that all programmable devices & equipment are protected by a surge suppressor by connecting them to it. This includes different types of machinery, as well as digital electronic equipment and other devices.

Inadequate Monitoring &Control

Problem: Delays in responding to potential concerns brought on by a lack of real-time monitoring & control might ultimately result in the escalation of the problem’s severity.

Troubleshoot: Every field device’s input and output voltage should be measured. If there is any noticeable voltage where it is not required, proceed with further caution. This could be a sign of low control circuit voltages caused by induction from power wires.

The field routing of semiconductors is frequently the root of this problem, and identifying it may take extensive troubleshooting. Generally, power conductor current influences the voltage generated into the control circuit wiring. To find these variations, a recording digital multimeter might be required.

A digital multimeter with the appropriate rating to measure and monitor voltage level can be utilized to measure the standard specification for the input voltage of electronic devices, like PLCs and VFDs, is + (or) – 10% of the rated voltage.

Control Wiring Terminations

Problem: Check the tightness of the terminations on control wiring. Electronic inputs are impacted, and at a loose termination point, any impacts of electromagnetic induction that the controls would typically have been able to withstand will be amplified. Sometimes, due to incorrect installation, wires fall away from pressure connectors.

Troubleshoot: Check that each wire is secure in its connection or terminal screw at its termination point. Tighten terminal screws.Power and control wire inspection and maintenance reduce electronically controlled equipment failures.

Overheating

Problem: Components can be damaged by excessive heat within the cabinet, which can also shorten their lifespan and raise the risk of electrical fires.

Troubleshoot: Execute an extensive inspection of the cabinet for any indications of overheating such as discoloration (or) burn marks, as well as any loose connections or damaged components.

Maintain constant surveillance on the temperature within the cabinet as well as the ventilation. Check to see that the fans & cooling systems are operating as they intended.

General Checklist of Electrical Cabinet Troubleshooting

A 10-point checklist for inspecting electrical cabinets that contain power and control circuits

1. Before opening the cabinet door, determine the voltage levels inside.

2. Follow electrical safe work procedures, which include setting approach boundaries and wearing PPE.

3. If at all feasible, stand to the side while opening cabinet doors.

4. Examine the components and wiring visually for any noticeable faults.

5. Pay attention to color-coding systems and distinguish between power and control wires.

6. Check that the power and control cables are sufficiently separated.

7. Examine the right angles at which the power and control cables cross.

8. Check if the voltages to the power sources of electronic devices are within the OEM (original equipment manufacturer) ratings by measuring them.

9. Check that the voltage at the field input & output devices is within specification by measuring it.

10. Tighten the terminal screws and inspect the integrity of the control terminations.

Conclusion

Incorrect grounding, and power & electronic conductor routing too near together & loose control wire & terminal screws, are typical but hard to identify reasons of equipment failure. Electrical cabinets inspecting properly, and frequent measurement of control voltage measurements can solve many unidentified technical problems.