Preventive maintenance for electric motors

Electric motor dependability and long life are ensured by a well-planned preventative maintenance procedure.

Essentially all electrical equipment has to have routine inspections and maintenance performed. By doing this, it ensures that electrical equipment is always in perfect operating condition.

In terms of electric motors, this is important. Throughout the motor’s longevity, regular motor checks should be performed at predetermined intervals.

By finding potential problems, routine inspections can avoid severe damage to equipment.

Regular Inspections

Motor rewinding and other maintenance plans for supply electric motors are focused on preventing major breakdowns rather than fixing them when they occur.

In order to get the best possible outcomes from their operation, motors need regular inspections.

In order for preventative maintenance programmes to be effective, complete inspections need to be performed on a regular basis. Additionally, a unique identification number and a record log should be kept for each motor located onsite. The records for the motor should include

- The name of the motor,

- The brand,

- The dates of any inspections, and

- The description of any repairs.

It is possible to determine the source of any malfunctions and cut down on ongoing issues if records are kept of what caused them.

Before carrying out any tests, each and every maintenance plan should first consult the technical documentation provided by the manufacturer.

There are basic procedures and maintenance tests that, when performed on three-phase motors, may provide a long life for the motor and contribute to its overall reliability.

Examining the service history, as well as inspecting for noise and vibration, are examples of simple tests. In addition to this, there would be

- Visual inspections,

- Testing of the windings,

- Maintenance on the brushes and commutator, as well as

- Bearings and lubrication.

The process of inspection and maintenance need to be methodical.

The significance of the motor, how it is put to use, and the environment in which the motor operates are all aspects that might influence how often inspections are performed and how thoroughly they are carried out.

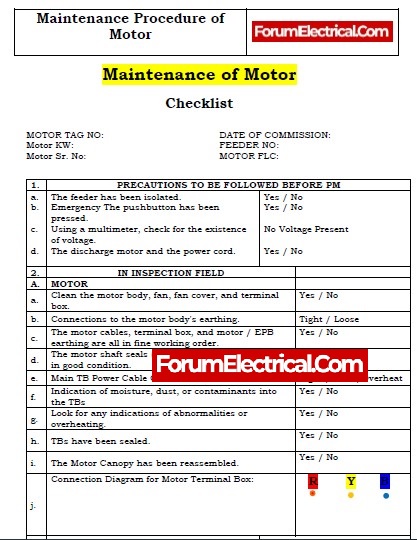

Therefore, a checklist or record schedule for inspections has to be adaptable and flexible enough to accommodate the requirements of each facility.

Maintenance of Motor Checklist