Table of Contents

- Purpose

- Scope

- Personal Protective Equipment (PPE)

- Responsibility

- Work Activity & Descriptions

- Test Procedure

- Step-1: Visual & Mechanical Inspection

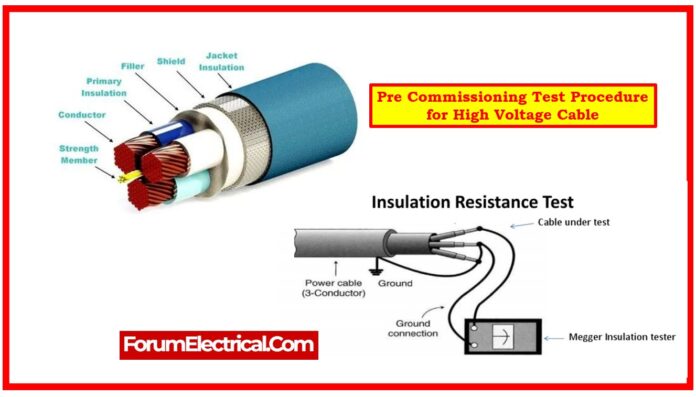

- Step-2: Insulation Resistance (IR) Test for EHV Cables

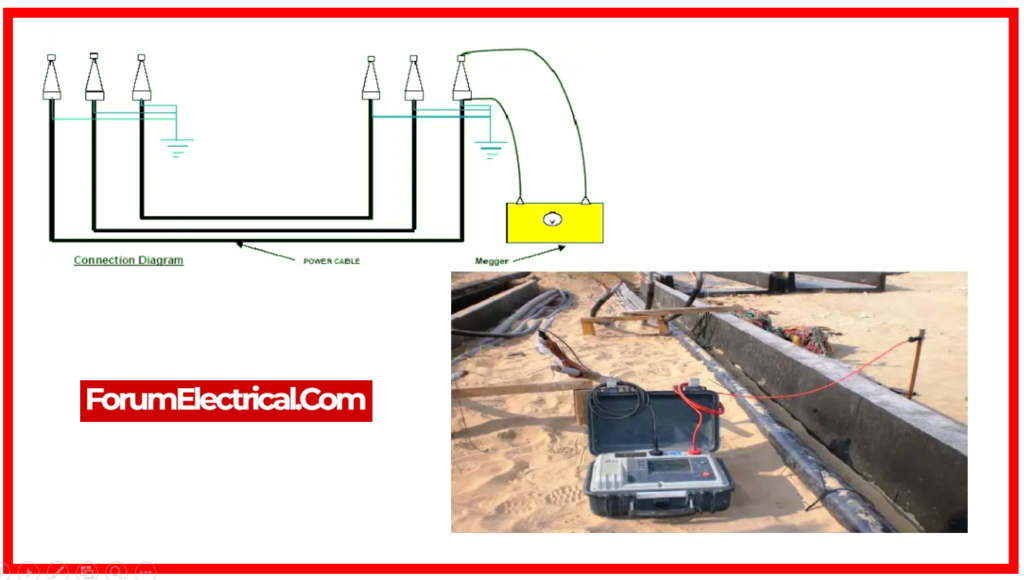

- Step-3: IR between Phase to Phase

- Step-4: IR between Phase to Earth

- Step-5: High Voltage (Hi-Pot) Test: HV Cable

- Control Measures

- Final Inspections & Area Restoration after Work Completion

- Communication & Sign-off Register

Purpose

This method statement is designed to carry out numerous pre-commissioning tests for switchgears in a systematic manner to assure the healthiness & performance of the HV cable.

Scope

This procedure covers the pre-commissioning test for HV cables, including

- High Voltage (Hi-Pot) test,

- Insulation Resistance test.

Personal Protective Equipment (PPE)

- Safety Helmet

- PPE Kit

- Hand Gloves

- Safety Shoes

- Safety Glass

Responsibility

Unit Heads/Regional Managers

Unit Heads/Regional Managers are responsible for health & safety management,

- Including planning and scheduling activities,

- Identifying and minimizing hazards,

- Adhering to legal and statutory requirements,

- Assisting the safety team with training and audits, and

- Ensuring compliance with safety rules and regulations.

Site Engineers

Site engineers are responsible for all areas of on-site health and safety and report to the Unit head / Regional Manager.

Their responsibilities include:

- Report any health and safety issues at work sites to the regional manager, unit head, or safety team.

- Coordinate with clients to obtain and return work permits.

- Communicate work content and hazards to working groups through meetings before each day’s start.

- Implement proactive measures to reduce accidents.

- Report incidents in detail.

- Use “Stop Work” in case of major safety violations.

Safety Engineers

Safety managers and regional safety engineers are in charge of giving health & safety advice & direction to their unit head, regional manager, and site engineers.

Their responsibilities include:

- Communicate all safety rules, regulations, and procedures to site engineers, regional managers, and unit heads.

- Follow up on audit non-conformances and assist regional managers/unit heads in taking remedial and preventive measures. Report and investigate any occurrences or near misses to high management.

- Create awareness among site engineers and regional managers, and plan a regular training program.

- Conduct daily toolbox discussion sessions to ensure workers are knowledgeable of workplace hazards.

- Ensure suitable PPE and safety equipment are available and used on-site.

- Report any problems affecting the health & safety at the work site to the unit head/regional management.

- Ensure that fundamental first aid facilities are provided on site.

- Ensure no harmful acts are undertaken on any site.

- Eliminating harmful conditions on-site promptly.

- Issuing safety challans for any violations.

Work Activity & Descriptions

Pre-Testing Checks

- Check the operating status of the ELCB (30 mA).

- Inspect power cable insulation for equipment.

- Ensure suitable earthing and rubber matting are accessible at the worksite.

- Use calibrated testing equipment and provide engineers with calibration results.

- Check the technician’s insulation hand tools.

- Check the test leads for insulation damage.

- Make sure proper PPE is provided at the site.

- Human supervision is required at both ends of the cable.

Resources: Tools and Equipment Required

For High Voltage Testing (Hi-pot test)

- High Voltage Test Kit

- Test Leads

- Insulation Tester (500 and 5000 V)

- Clamp meter and Insulated Hand Tools.

For Insulation Resistance Measurement Test (IR Test)

- Clamp meter

- Test Leads.

- Insulation tester (500-5000 V)

- Insulated hand tools

Test Procedure

Step-1: Visual & Mechanical Inspection

- Compare the cable data to the designs and requirements.

- Check exposed parts of cables for the physical damage.

- Inspect compression-applied connections for proper cable alignment and indentation.

- Inspect the shield grounding, cable supports, and terminations.

- Ensure that visible cable bends meet (or) exceed the ICEA and manufacturer’s minimum published bending radius.

- Inspect the fireproofing in the common cable places.

- If cables are terminated via window-type current transformers, inspect to ensure that neutral & ground conductors are correctly arranged and shields are correctly terminated for the operation of protective devices.

- Inspect for proper identification and organization.

- Check the cable jacket & insulation condition.

Step-2: Insulation Resistance (IR) Test for EHV Cables

- Obtain a work permission from the client.

- Ensure there is no energy in high voltage (HV) cable.

Step-3: IR between Phase to Phase

- Connect the first conductor for measuring cross insulation to the megger’s line terminal.

- Connect the remaining conductor to the earth.

- Connect the sheat to the earth terminal of the megger.

- Leave the conductor at the other end free.

- Turn on the megger and press the test button.

- Discharge the potential with a separate earth rod.

- Turn OFF the megger.

- Repeat for the other conductors.

Step-4: IR between Phase to Earth

- Attach the conductor to the megger’s line terminal.

- Attach the guard to the last remaining conductor.

- Loop the armor and shielded conductor to the soil at the closest place and in the megger.

- Repeat the previous steps for the additional conductors.

- Leave the other end free.

- Turn the megger ON & press the test button to record the reading.

- Discharge the potential using a separate earth rod.

- Turn the megger OFF.

Step-5: High Voltage (Hi-Pot) Test: HV Cable

- Obtain the client’s work permit.

- Ensure the bus bar terminal has no voltage and is earthed.

- During high voltage testing, earth all equipment associated to cable installation, including switches, instrument transformers, and busbars, and maintain clearance from other equipment and framework to minimize flashovers.

- Attach the Hi-Pot kit with the ELCB 30mA.

- Connect the test lead to the conductor and cable armor.

- Connect the other conductors (other phase) to the ground. Then, turn on the test kit, apply voltage to the cable, and take the reading. Finally, use a discharge rod to discharge the cable potential.

- Connect the clamp meter to the discharge rod, touching the cable points, to ensure zero voltage.

- Perform the preceding methods to measure the other phases.

Control Measures

- Testing engineers provide OCP for IR and Hi-Pot tests for HV cables.

- Make sure PTW system in setup for the specific bay.

- Ensure equipment supply is dead.

- Prevent unauthorized access to the testing area.

- Barricade the area with warning tape.

- Conduct job-specific toolbox meetings and supervise the area.

- Use calibrated equipment and insulated hand tools.

- Avoid power cable joints and supply via ELCB.

- Avoid working alone.

- Wear arc flash suits and avoid high-potential tests.

- Use proper insulated hand gloves.

Final Inspections & Area Restoration after Work Completion

- Remove the barricading tapes and disconnect the temporary supply.

- Make sure that the space is free of any loose materials or tools.

- As you depart, make sure the area is neat and clean.

Communication & Sign-off Register

Communicate to all staff in meetings, and ensure that all personnel sign it.