The safety of those who are conducting tests and those who are working on construction projects should always be the top concern.

- 1). Proper Safety Gear

- 2). Power Isolation Procedures

- 3). Check the Correct Panel/Equipment

- 4). Tagging and Padlocks

- 5). Delegation of Work

- 6). Clear & Precise Instructions

- 7). Restricted area for unauthorized Personnel

- 8). Test Plan & Circuit Diagram

- 9). Use of Testing Equipment

- 10). Voltage Application for Transformers

- 11). Handling CT Secondary Circuits

- 12). Discharge after Testing

- 13). Motor Work Precautions

- 14). Control of Switchgear

- 15). Use Proper Tools and Instruments

- 16). Temporary Jumpers

- 17). Working with Unfamiliar Equipment

- 18). First-Time Energizing of Equipment

- 19). Transformer Paralleling: Precautions

- 20). Voltage Applied to PT Secondary Circuit

- 21). Precautions for the Circuit Breaker Mechanism Box

- 22). Replacing Blown HRC Fuses

- Testing Procedure

- Checklist

In order to ensure everyone’s safety, the following are basic guidelines:

1). Proper Safety Gear

Use safety shoes, a helmet, safety gloves (rubber-electrical), a rubber mat, fire extinguishers, and other safety equipment.

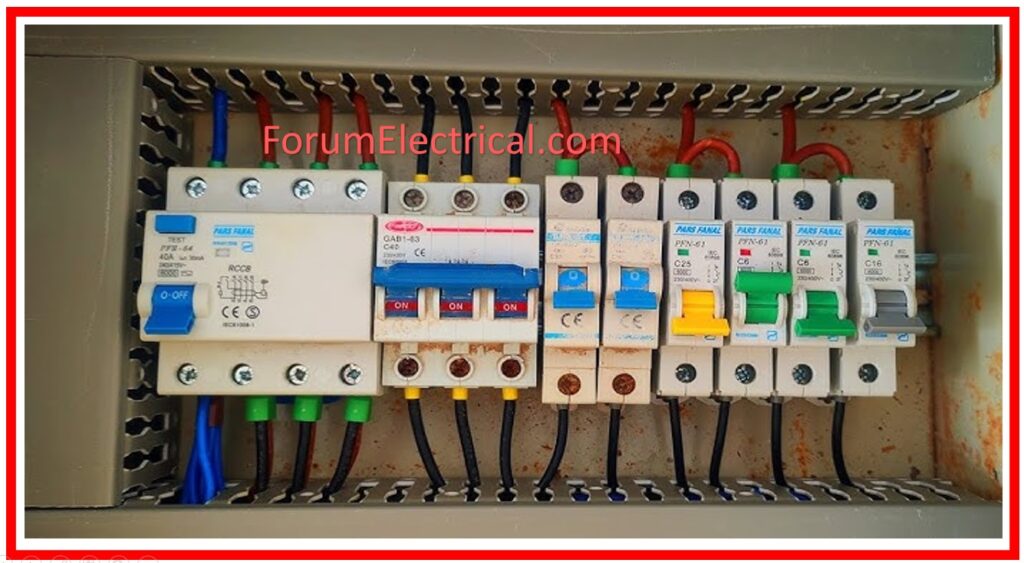

2). Power Isolation Procedures

Before working on power circuits (LT or HT), disconnect all power sources by opening and closing circuit breakers.

Close earthing switches or, if not available, do local earthing.

3). Check the Correct Panel/Equipment

To avoid accidents caused by opening the wrong panel or equipment, double-check that work is started on the correct panel or equipment.

4). Tagging and Padlocks

To prevent illegal access, tag all breaker boxes and switches and use padlocks wherever possible.

5). Delegation of Work

Delegate work exclusively to qualified individuals after validating their credentials and abilities.

6). Clear & Precise Instructions

To avoid misunderstandings, give clear and specific directions.

7). Restricted area for unauthorized Personnel

8). Test Plan & Circuit Diagram

Before beginning any test, make a detailed plan, including a circuit schematic for understanding.

9). Use of Testing Equipment

Carefully handle test equipment such as meggers, earth testers, multimeters, & high-voltage test sets.

Secure both ends of cables during testing & verify that responsible workers are properly stationed.

10). Voltage Application for Transformers

To avoid accidents, apply voltage to the transformer’s low-voltage side with caution.

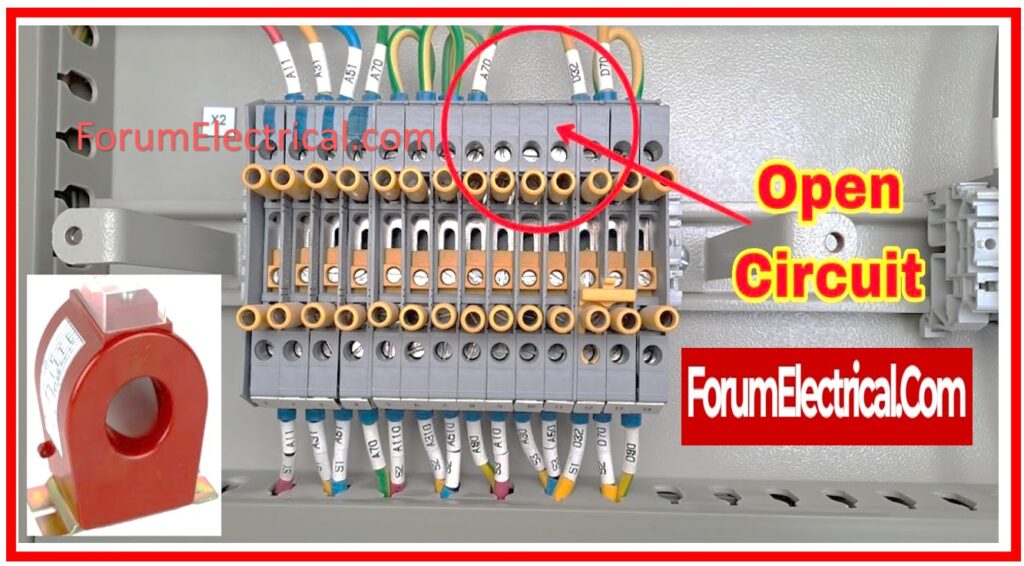

11). Handling CT Secondary Circuits

When there is current flowing through the primary circuit, do not open the CT secondary.

During a primary injection test, start with 10% of the rated current & verify all secondary circuits before escalating to the full rated current.

12). Discharge after Testing

After performing megger or high-voltage testing, connect the equipment to earth with an insulated wire.

13). Motor Work Precautions

Before working on a motor, make sure the controller is disconnected & tagged out.

14). Control of Switchgear

When working on equipment, make sure the switchgear is controlled locally. Control should only be returned after the work is completed.

15). Use Proper Tools and Instruments

Always utilize suitable tools and devices, and avoid line testers. Use a multimeter, making sure it’s set to the proper parameter and range.

16). Temporary Jumpers

Use long jumpers during testing to draw attention if not removed.

17). Working with Unfamiliar Equipment

Before you start working on unknown equipment, carefully read the operating handbook.

18). First-Time Energizing of Equipment

When turning on equipment for the first time, remove all staff from the area and make sure fire extinguishers are in place.

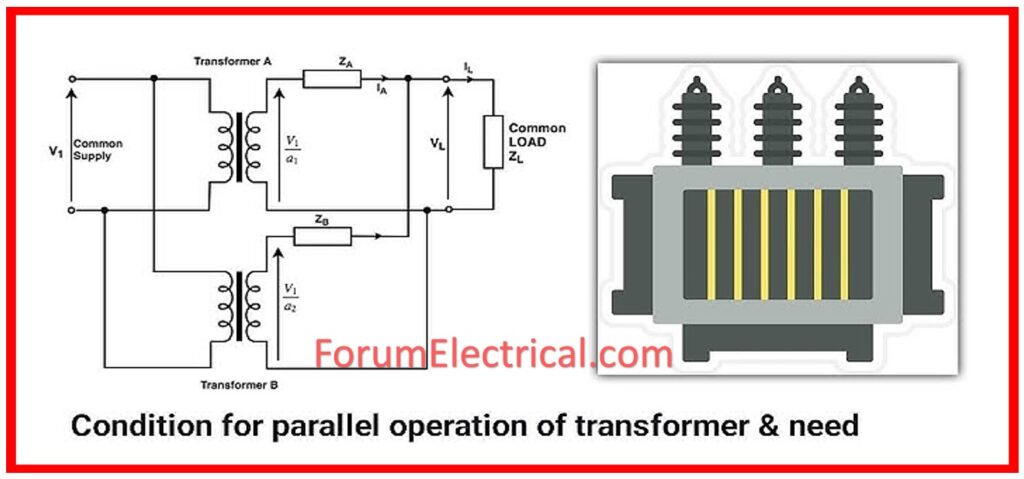

19). Transformer Paralleling: Precautions

Before paralleling transformers, do a low-voltage phasing check to ensure that there is no voltage across the bus coupler breaker once both transformers are turned on.

20). Voltage Applied to PT Secondary Circuit

Isolate PTs by removing the control plug (or) secondary fuses prior to providing electricity to the PT secondary circuit.

21). Precautions for the Circuit Breaker Mechanism Box

Always discharge the closing & tripping springs in the circuit breaker mechanism box by turning off the control power, tripping and closing the breaker, and then tripping again.

22). Replacing Blown HRC Fuses

Do not replace a blown HRC fuse with bare wire; instead, install a new HRC fuse with the appropriate rating.

Testing Procedure

Energizing Reliability: Testing and Commissioning Guidelines for Power Systems