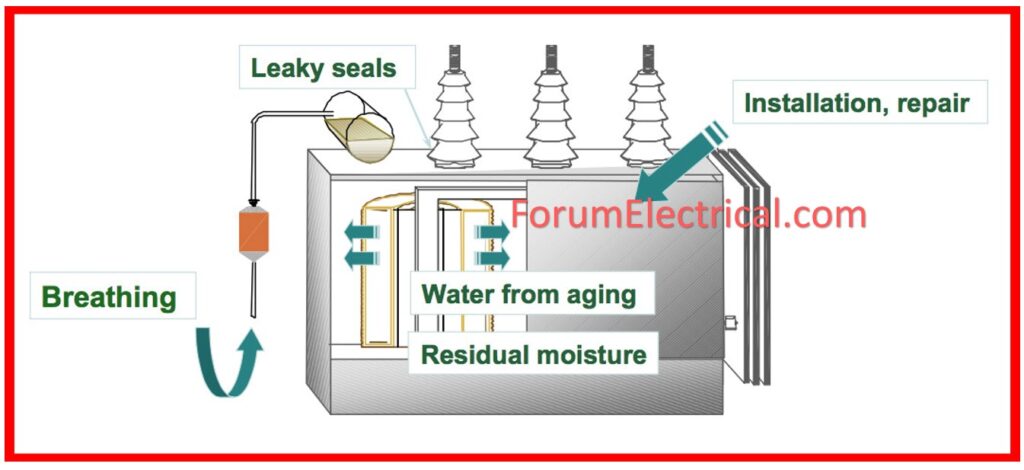

The transformer body is influenced by moisture; this will cause the insulation to have lower electrical resistance and age at a higher rate, and therefore it needs to be dehumidified.

- Drying Out of Transformer

- Purpose of Transformer Drying Treatment

- Drying of Transformer Insulation: When is it Applicable?

- 1). Hot Oil Circulation with High Vacuum Filter Machine

- 2). Vacuum and Nitrogen Cycle with Extra MSE Heater

- 3). Induction Heating Method

- 4). Short Circuit Method

- 5). Hot Oil under a Vacuum

- Drying Standard of Transformer Insulation and Drying Treatment

With the development of production, more and more thorough drying equipment and drying technologies will appear to enhance the drying process.

Drying Out of Transformer

Since transformer winding is very much sensitive to moisture and tends to absorb moisture from the humidity of the atmosphere whenever exposed for a long period during construction or repair as the case may be, the drying out of the transformer for the purpose of removing moisture before putting it to use is very much recommended.

The process of drying out of a transformer is one that is very delicate and deserves a lot of consideration. If the dry out process is done wrongly, lots of damage could occur to the transformer insulation/oil through overheating etc.

Dry out is a very sensitive process in that no transformer should be left alone during any stage of the dry out process.

During the dry out period for the transformer, it should be closely monitored, and all the observations done should be documented.

It should also not be exposed to rain or high atmospheric humidity, if so the drying out of the transformer windings will take considerable time to complete.

The post highlights procedures for drying of transformers before they are used.

Purpose of Transformer Drying Treatment

- Transformer drying is therefore meant for elimination of moisture in the transformer insulating material in order to increase insulation resistance and flash over voltage.

- Transformers containing voltage more than 3kV are required to be dried.

- Transformer body is mainly consisting of iron core and coil and insulation assembly, assembly before transformer oil application, have to go through with the drying process in other to get rid of the moisture content in the insulation material and the formation of the gas, so that, it will regulate the water content within the set limit as it postulates in the product quality standard, as this will ensure the transformer has adequate power strength as well as operating life.

- In the case of high voltage transformers, it is desirable to have the insulation materials to be having a water content of not more than 0. 5%.

Drying of Transformer Insulation: When is it Applicable?

Transformer insulation has to be dried in order to fully conform to the presently used norms and standards.

The following conditions require transformer drying:

- The presence of moisture was revealed on the active part or in the tank.

- A transformer was stored without oil for a period that was more than one year.

- Self-indicating silica gel that is indicated by the change of its blue color to white when it is packaging moisture.

- An outside air was in contact with an active part of a transformer for more than the set time.

- It was also seen that the transformers did not get to the possibility of their insulation to the necessary standard values even when dehydrated.

There are many methods of dry out being adopted by different agencies; some of them are as under:

1). Hot Oil Circulation with High Vacuum Filter Machine

2). Vacuum and Nitrogen Cycle with Extra MSE Heater

3). Induction Heating Method

4). Short Circuit Method

5). Hot Oil under a Vacuum

1). Hot Oil Circulation with High Vacuum Filter Machine

The best way of drying out is by circulating hot oil in a high vacuum filter machine.

- To start with, oil is pumped from the bottom and supplied to the top of the transformer tank.

- This will help to flush out any of the settled moisture /impurities.

- After 12 to 24 hours of circulation in this way, the circulation is reversed;

i.e., the oil is pulled from the top of the tank and is supplied at the bottom for normal circulation during the dry out period.

- The oil temperature of the tank, filter machine outlet temperature, vacuum in filter machine and IR.

- Temperature difference between oil outlet and inlet should be recorded on a regular basis and there should be a log book for the same to be prepared.

- During the dry out period it is required to cover / lag the transformer tank adequately to regulate the temperature of the oil and avoid heat loss.

- The primary requirement needed to be taken during dry out is that the temperature of the main tank oil should not go above 600C and that of the filter machine should not go above 650C.

- After oil circulation at constant temperature for 4-5 days and attaining the oil parameters to the limits such as BDV 70 KV & PPM 10 the dry out may come to be regarded as complete.

The cooler bank and the OLTC oil compartment should also have their own hot oil circulation before energization.

2). Vacuum and Nitrogen Cycle with Extra MSE Heater

This dry out procedure is employed in many transformers with high exposure.

In order to remove the moisture more quickly when winding it is necessary to increase the temperature of the core and winding to 60 – 650C.

- The method of gradual heating at 650C and vacuum 0. 3 torr shall be applied initially and constant observation of extraction of moisture.

- If the extraction rate is less than 50 ml per hour, for at least 3 hours then this process is prevented. After that dry N2 with the dew point of -500C is then pumped into the transformer tank and left for 24 hours.

- Pressure of N2 shall be between 0. 15 and 0. 2 kg/cm2.

- Following 24 hours dew point of N2 is measured and if it is -300C or so then drying is said to be over.

- In any case, heating and vacuum shall be repeated.

- N2Temperature has a linear relationship with Dew point measurement.

- For heating generally it is recommended to install concealed heaters of minimum 2 KW.

- Following the heating of the tank (which contains N2 gas) up to a temperature of 650C and maintaining the temperature for one day, it is required to evacuate the tank through vacuum pump and take more than one day.

- During vacuum pulling the water is collected: If extraction of water is higher, then N2 and vacuum cycle may be repeated for 2-3 cycles.

- The N2 in the tank is acting as a heat transfer media to the core and coil in the tank. In order to control heat loss, the tank should be adequately covered all through the process of dry out.

- In the filling of this cylinder, the determination of the dew point of the N2 gas was also done (-500C).

- The temperature of the dry air after compressor and of tank after filling for 24 hours may be taken and if the value of tank dew point is close to the cylinder dew point (approx-300C the dry out process is regarded as complete.

- Similarly the water from the tank outlet is collected during the drying process.

- At the time of termination of dry out, the water collection from the transformer tank may have to be monitored continuously and this value should be constant of the last three readings taken hourly and should be less than 50 ml. per hour.

- Following the dry out, other activities that may be done include the oil filling and may be closed up.

Another recommendation before charging of the transformer was the separate hot oil circulation for cooler and OLTC oil compartment.

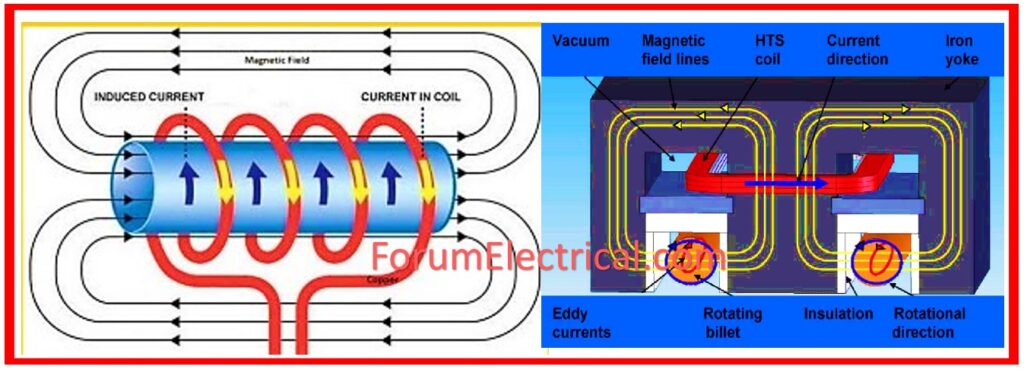

3). Induction Heating Method

This method of heating is usually used to increase the transformer temperature during the drying out process so as to hasten the process of evaporation of moisture.

- In this method the transformer tank is wounded with cable (preferably welding cable) by using wooden separators.

- Three phase (or) single phase supply source is provided to the coil and permits current to flow in coiled form or in the form of coil current.

- Induction effect causes the tank wall to heat and this heat transfer will go to the core and coil through the oil.

- The above stated methods opted for in the manufacturing process will cause the evaporation to start very fast because of the high temperature of the winding.

- To monitor the temperature of the tank wall a physical method known as thermometers on the tank walls can be used.

- Moisture removal will here be through oil which will be under circulation.

- The remaining procedure of dry out will be the same to the one explained in method I & 2.

4). Short Circuit Method

- In this method the LV winding of the transformer is connected with copper bar/cable suitable to take full load current and kept shorted.

- This limited voltage is connected to the HV winding to let through the amount of current required and does not exceed the full load current.

- This will help in raising the temperature of core and coil to speed up the evaporation of moisture.

- The monitoring of the temperature of the oil as well as winding needs to be done appropriately with the help of OTI as well as WTI.

- In no case should the WTI temperature exceed a figure that is more than 750C and OTI 650C.

- This method should however not be used for large transformers with directed oil flow having no ONAN rating since it is prone to local overheating.

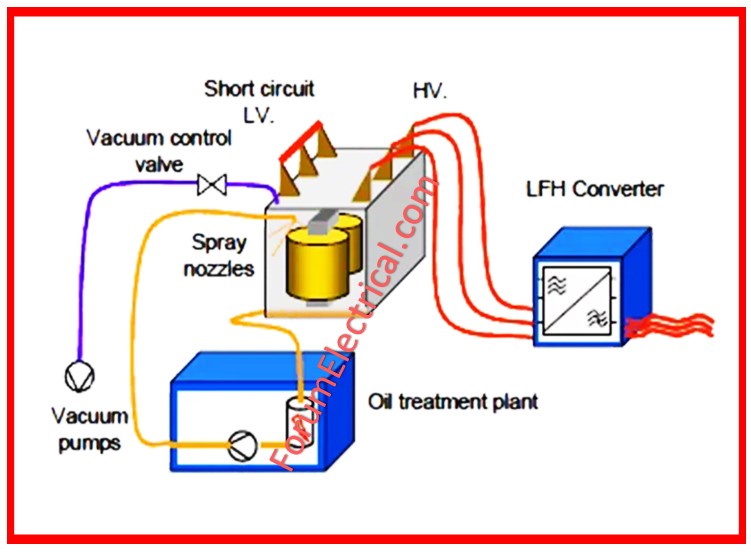

5). Hot Oil under a Vacuum

- In this method the hot oil is directly applied on the core and the coil with the help of partial vacuum.

- Heat of oil is absorbed by core and winding and it enhances the rate of evaporation at vacuum.

- With the reduction of the vacuum in the tank, there is also less loss of heat.

- The hot oil mist should be continued by connecting a filter machine to draw oil from the bottom and fed at the top.

- This is done by providing an appropriate pipe having a bus pipe connected with numbers of branch pipes of the required diameter with holes in it at certain intervals all along the length for oil to drip onto the coil.

- For the fitting of this pipe with a filter machine Different openings used on the tank can be applied.

- The measurement of temperature of core & coil could be done with the help of thermocouple.

- The depressing effect of core and winding by hot oil under partial vacuum is to be continued for spraying hot oil on core & winding for moisture extraction through vacuum pump.

- Upon completion of this drying out process, oil will be put in the tanks under vacuum up to the top yoke.

- The circulation of oil in OLTC and cooler should be conducted independently before charging.

Drying Standard of Transformer Insulation and Drying Treatment

Drying Standard

Transformer insulation oil is free from moisture. The minimum breakdown voltage of the oil shall not be less than seventy five per cent of the delivery data.

It is mandatory that the value of insulation resistance should not be below 70% of that which has been obtained from the factory.

The tangent of medium loss Angle shall not be more than 130% of the manufacturer’s specification.

Transformer Drying Conditions

If the body is being repaired or is in the process of being installed, the body is exposed to the air for more than the time specified herein.

The insulation resistance and absorption ratio are used for measurement of moisture exposure of the transformer winding.