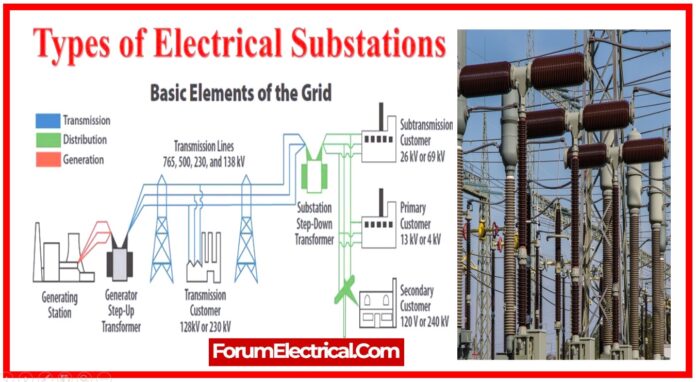

The need for electrical power is rapidly increasing, which can be met by power generation substations.

There are several types of power generation substations, including thermal, atomic, and hydroelectric.

Substations are being constructed in various areas based on the availability of different resources, however these locations can’t be closer to load centers.

The load center can determine the real power utilization. Power must be transmitted from the substation to the load centers.

As a result, this function necessitates the use of large transmission networks.

Power is generated very efficiently at low voltage levels; but, supplying power at high voltage levels is relatively affordable.

To maintain high & low voltage levels, a number of switching and transformation stations must be constructed between the generating facility and the consumer’s ends.

In general, these two stations are referred to as electrical substations. This post describes many types of substations.

What is a Substation?

A substation is a high-voltage electrical system that can be utilized for controlling equipment, generators, and electrical circuits. Substations are mostly utilized for converting alternating current (AC) to direct current (DC). Some types of substations are small in size, with an integrated transformer and associated switches. Other substations are massive, with a wide range of

- Transformers,

- Circuit breakers,

- Equipment, &

- Switches.

Importance of Substation

- An electrical substation is an important part of the electrical system since it functions as a bridge in moving electricity from the power producing unit to the end users by working to speed up (or) slow down the current as needed.

- Transformers, insulators, and circuit breakers are used in substations to regulate power issues such as frequency, voltage, AC to DC conversion, and P.F.

- Substations serve a significant function in generating, transmitting, and distributing safe and dependable energy to residences.

Types of Substations

There are different types of electrical substations based on their nature and power handling capabilities. Substations are classified generally into the following four categories depending on numerous aspects:

- Types of Substations according to Application

- Types of Substations according to Services

- Types of Substations according to Operating Voltage Levels

- Types of Substations according to Location and Design

Types of Substations according to Application

The following is a classification of the substations depending on application.

1). Step-up Substation

2). Step-Down Substation

3). Primary Substation

4). Secondary Substation

5). Distribution Substation

6). Mobile Substation

7). Industrial Substation

8). Mining Substation

1). Step-up Substation

Because generation occurs at lower voltages, the step-up substations are directly connected to producing stations.

As a result, these voltages must be increased in order to transmit electrical energy across longer distances more efficiently. The step-up substation can include circuit breakers, which are used to shut down transmission & generation circuits when necessary.

The required voltages leaving the step-up transmission must be analyzed in light of the customer’s requirements.

2). Step-Down Substation

Step-down substations are linked to load centers because different voltage levels are required for different loads. Step-down substations can adjust transmission voltage levels to 33kV. The lines from the substation then serve as a source for the distribution substation. Furthermore, some of the electricity is drawn from the substation line and used for industrial reasons.

3). Primary Substation

Primary grid substations are connected to bulk load centers via primary transmission lines. Voltages are stepped down in several voltage ranges for secondary transmission.

4). Secondary Substation

Secondary substations are located along secondary transmission lines close to loads. The voltages are further step down for distribution purposes.

5). Distribution Substation

The distribution substations are positioned where primary distribution voltages are stepped down. These voltages are for consumers to utilize with their actual loads. These substations are equipped with high-voltage bearable wires & conductors that include one neutral to ground and four live wires. The three-phase voltage is 440 volts between conductors and wires, while the single-phase value is around 230 volts between neutral to ground & conductor.

Substations can be classified based on the type of equipment utilized and the configuration:

- Conventional – Outdoor with air-insulated equipment.

- Indoor, with air-insulated equipment.

- SF6 Gas Insulated Substation

- Outdoor Type – With gas-insulated equipment.

- Indoor Type – With gas-insulated equipment.

- Composite substation (or) hybrid substation is a combination of the above two.

6). Mobile Substation

Mobile substations provide a specific purpose and are transitory in nature, primarily for large construction projects. A mobile substation is designed to meet the power requirements of under-construction structures. These substations provide temporary electrical power and are easy to maintain. It provides outstanding safety against blackouts, fires, weather disturbances, and sabotage, among other things.

7). Industrial Substation

Industrial substations, also known as bulk substations, are usually referred to as distributive substations; however, these are merely for dedicated customers, such as industries that require bulk power supply.

8). Mining Substation

The mining substation is unique in that it must be properly built to ensure that its electrical energy is operated safely. This substation is dedicated to controlling the electrical power supply from surface to the underground mine power station.

Types of Substations according to Services

Substations are classed according to a wide range of factors, one of which is based on the services they deliver and it include different types:

1). Converter Substation

2). Switching Substation

3). Collector Substation

1). Converter Substation

Converter substations include technology that adjusts the frequency of electricity from higher to lower, as well as the ability to convert AC to DC or reverse.

2). Switching Substation

One important function of these switching stations is to switch the power line without changing the voltages because they are located between the transmission lines. It also isolates and de-energizes failed equipment, allowing the grid to run more reliably.

3). Collector Substation

These substations are generally utilized in distributed power generating projects such as wind farms and hydroelectric projects, where electricity flow from different sources is collected and delivered to the grid by increasing the transmission voltage.

Types of Substations according to Operating Voltage Levels

The classification of substations below depends on the voltage levels that operate, and it may vary by area.

1). High Voltage Substations (HV Substations) (11–66 KV)

2). Extra High Voltage (EHV) substations (132-400 kV)

3). Ultra-High Voltage (UHV) Substations (Operating >400 KV)

4). Direct-Current High Voltage (HVDC) Substations (±250, 400 or 500 kV)

1). High Voltage Substations (HV Substations) (11–66 KV)

High voltage substations, particularly those running at 11 kV to 66 kV, perform a significant part in the electrical power system.

They operate as intermediaries, converting high voltage electricity from transmission lines into a lower voltage appropriate for distribution to consumers and companies.

HV substations are vital infrastructure that operate at high voltages, raising safety concerns.

They frequently remain in fenced areas with limited access and are provided with a wide range of safety features such as

- Grounding systems,

- Warning signs, &

- Personal protective equipment for employees

2). Extra High Voltage (EHV) Substations (132-400 KV)

EHV substations are essential parts of electric power transmission networks.

They convert ultra-high voltage electricity from power plants into levels appropriate for effective long-distance transmission via overhead wires. They also reduce extra-high voltages to distribution levels.

EHV substations use heavy-duty equipment such as

- High-capacity transformers,

- Circuit breakers,

- Switches, and

- Instrument transformers

that are specifically designed to handle extremely high voltages ranging from 132,000 to 400,000 volts.

Insulation, lighting protection, clearances, and safe, reliable operations all require strict design considerations.

Given the volume, price and essential relevance, EHV substations require enormous land tracts, rigorous physical protection, monitoring, and skilled maintenance.

They are critical for bulk power transfer and constitute the foundation of transmission grid infrastructure.

3). Ultra-High Voltage (UHV) Substations (Operating >400 KV)

UHV substations operate at record transmission voltages beyond 400kV, with some reaching 1,100kV.

They use cutting-edge technology to boost voltages from mega-capacity generators to levels appropriate for long-distance bulk power transfer via high voltage overhead lines across states.

UHV enables the effective transfer of large blocks of electricity across long distances to load centers while lowering transmission losses.

- Specialized UHV transformers,

- Reactors,

- High-voltage circuit breakers,

- Instrument transformers, and

- Switchgear employing technologies such as gas or air insulation

are important parts of equipment.

To ensure safe, dependable, and efficient operations at ultra-high voltage levels, sophisticated control systems and automation are used, as well as careful design considerations for the insulation coordination, clearances, electric field management, audible noise control, and environmental concerns.

4). Direct-Current High Voltage (HVDC) Substations (±250, 400 or 500 KV)

HVDC transmission systems use power electronics to convert alternating current electricity to high voltage direct current, with the purpose of delivering bulk power over large distances.

HVDC provides the effective transfer of big blocks of power over very long distances using land or subsea cables.

- Converter transformers,

- Thyristor (or) Voltage source converter valves,

- Smoothing reactors,

- Harmonic filters, and

- Specialist switchgear

- Are all vital components of equipment.

HVDC operates at transmission voltages ranging from ±250-500kV DC via overhead lines or mass impregnated undersea cables with solid (or) liquid insulation.

Converter stations employ air (or) gas insulated switchgear that is designed to resist large DC currents.

Advanced automation and control technologies provide a consistent operation. Stringent clearances, insulation coordination, and electric field management are required for dependable and safe performance.

HVDC technology reduces transmission losses over large distances.

Types of Substations according to Location and Design

The following substation types, along with brief descriptions based on location and design:

1). Outdoor Substation

2). Indoor Substation

3). Pole-mounted Substation

4). Underground Substation

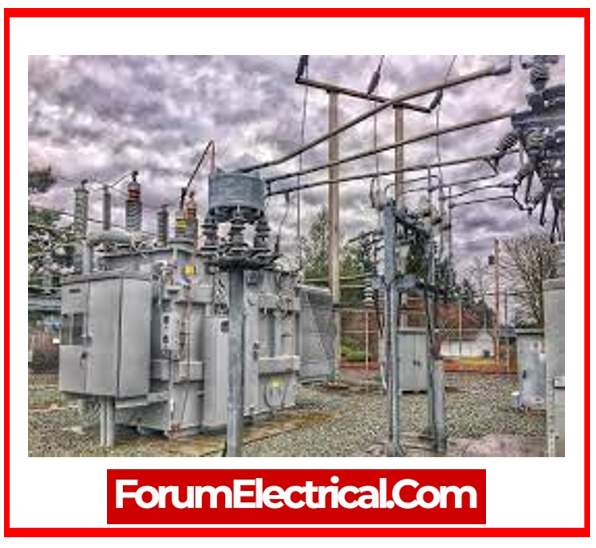

1). Outdoor Substation

The outdoor substations are built in the open air.

These are also referred to as 400KV, 132KV, 220KV, and 66KV substations, among other names. Gas-insulated substations are now constructed for high-voltage systems.

2). Indoor Substation

Indoor substations are often constructed beneath a covered area or roof and operate at lower voltages.

There are several names for these substations, such as 33KV and 11KV substations.

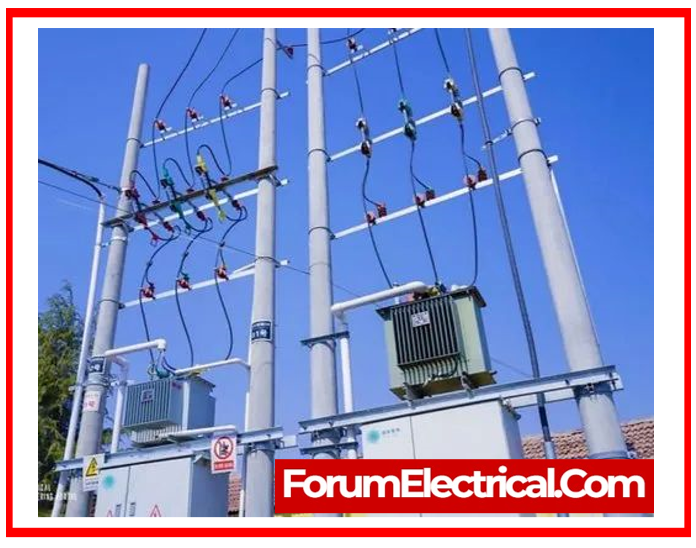

3). Pole-mounted Substation

Pole mounted substations are mostly distribution substations built on a structure of two, four, or even six or more poles.

In such substations, distribution transformers must be mounted over poles, along with isolator switches.

The single pole is also called as the H pole, while the four pole structures are more relevant, running at 25KVA, 125KVA, and 225KVA.

4). Underground Substation

The underground substations are embedded (or) subversive. These substations are constructed in crowded areas where it is not feasible to construct open-air or outdoor substations.

However, some substations have extremely complex designs. Such substations typically have voltage levels between 34500/19920 and around 4160/2400 volts.

Within this post, we have discussed in extensive detail the classification of substations according to the application, design, location, service, operational voltage levels, and other factors. Although there are an immense number of additional terms, such as Grid Substations, Town Substations, Traction Substations, and so on, these are more or less classified according to the categorization that was already described.