- What is an Arc Flash?

- What is the principle of Arc Flash?

- What are the primary causes of Arc Flash?

- 5 Ways to Avoid an Arc Flash

- Arc-Flash Relay

- Energy Formula for Arc Flash

- What is the Arc Flash Duration?

- What is an Arc Blast?

- Difference between Arc Flash and Arc Blast

- Arc Flash vs Arc Blast

- Types of Arc Flash

- What is the minimum voltage for Arc Flash?

- What is Arc Flash Testing?

- Comparison of Arc Flash Standard

- Arc Flash Boundary

- Arc Flash Analysis

What is an Arc Flash?

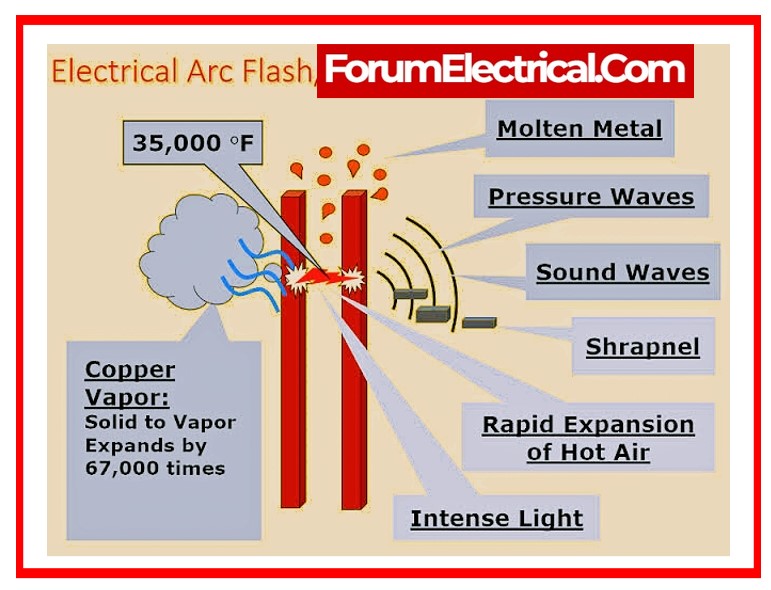

An arc fault is a type of electrical fault caused by the breakdown of an insulating medium between two conductors, where the energy is sufficient to sustain an arc across the insulator (usually air), resulting in extreme amounts of light (arc flash), immense heat (up to 19,000 degrees Celsius), and an explosive pressure wave (arc blast).

The terms “arc flash” and “arc fault” are often used concurrently, the earlier one refers to the light generated during an arc fault.

These pressures combine to generate a hazardous state capable of

- Vaporizing metal,

- Destroying equipment, and

- Endangering anyone in close proximity.

The term “arc flash” refers to low impedance connections in a power system that allow unwanted electric discharge to pass from a specific voltage phase to another or ground.

This causes a rapid rise in temperature & pressure in the air between the electrical conductors, resulting in an arc burst. Arc bursts & the resulting heat may cause

- Fires,

- Pressure waves, and

- Flying shrapnel,

causing significant damage to people and property. These explosions generally strike without notice, completely damage electrical equipment, and cause severe injury (or) death to personnel present inside the border of the arc flash.

What is the principle of Arc Flash?

The principle of arc flash is based on the quick release of energy caused by an electrical arc between conductors (or) between a conductor & ground. This happens when the insulation fails or an unintended connection is created between two electrical wires.

When an arc flash occurs, it results in a burst of high heat, light, & pressure.

The arc can reach temperatures of several thousand degrees Celsius, forcing adjacent materials to evaporate and form plasma.

The rapid expansion of air & evaporated materials produces an explosion-like effect, propelling molten metal and debris at tremendous speeds.

This energy discharge causes considerable risks to those around, including serious burns, blast injuries, & equipment damage.

Understanding arc flash principles supports in the

- Development of safety rules,

- Risk assessments, &

- Protective measures designed to reduce the probability and

- Impact of arc flash occurrences.

What are the primary causes of Arc Flash?

Poor Maintenance

Several arc flashes are a direct consequence of inadequate maintenance. Over a period of time, electrical equipment can corrode and wear down, resulting in insulation failure and an increased chance of an arc flash.

Loose connections can potentially induce arcing or overheating, resulting in an arc flash incident.

Environmental Factors

Environmental elements such as moisture, dust, dirt, or condensation can all cause problems with electrical insulation, increasing the chance of an arc flash.

Human Errors

Improper work (or) equipment failure has also been linked to an increased risk of arc flash.

When personnel fail to follow standard lockout tagout protocols or fail to wear appropriate personal protection equipment while working with electrical systems, they increase the danger of an arc flash.

Other human errors, such as accidentally touching electrified circuit components or wrongly installing (or) wiring equipment, might also result in an arc flash occurrence.

Employees should also be mindful of warning indications, such as excessive heat (or) noise, that indicate equipment breakdown is addressing.

Other Causes

Arc flash happens when numerous electrical wires are positioned near together and substantial fault currents flow through them.

Ionization of air can occur due to several reasons.

Potential differences create a low resistance channel between conductors, allowing current to flow via the air gap.

It is understood that low voltage equipment is safe against arc flash, although arc flash hazards might be higher at low voltages due to large fault currents.

Most occurrences in low voltage systems occurred by human error, such as a tool slipping when a worker is working on electrical equipment.

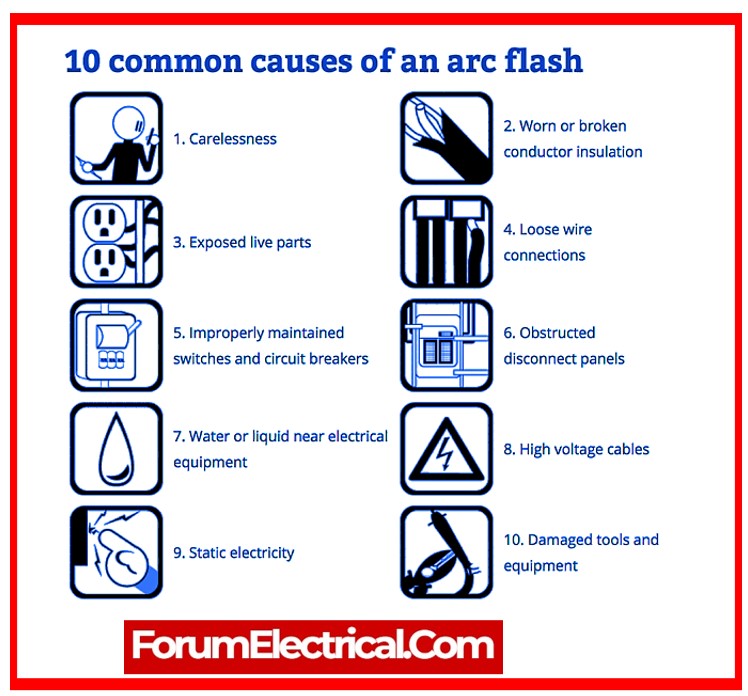

Arc flash can also occur due to:

- Carelessness or mishaps include touching inappropriate surface with the test probe.

- Improper tools, installation, and labor practices.

- Not enough electrical safety awareness & training.

- Use of defective electrical materials or equipment.

- Obstruction in disconnect panels.

- Insulation deterioration, gaps, or wear and tear.

- Dust, dirt, & corrosion on electrical conductors.

- Improper preventative maintenance of circuit breakers and switches

- Exposed live components, loose connections, or corrosion

- Static electricity and high voltage cables.

- Expose of electrical equipment to water (or) other liquid.

5 Ways to Avoid an Arc Flash

Proper training, safety practices, and equipment can reduce the risk of arc flash. Here are five important precautions measures to take:

- De-energize the Equipment and Remove Personnel

- Evaluate the Hazard & Use Low-Risk Technology

- Optimize Electrical Systems & Controls

- Increase Safety Training & Risk Awareness

- Develop & Implement a Strict Safety Program

De-energize the Equipment and Remove Personnel

It is essential to reduce the potential hazard as much as feasible. Avoid working on electrified electrical equipment and exercise caution when testing or re-energizing it.

Utilize remote racking technology to operate circuit breakers remotely from the arc flash boundary rather than putting personnel in danger of injury or death.

Evaluate the Hazard & Use Low-Risk Technology

Collect data on the facility’s power distribution system and conduct short circuit & protective device coordination assessments to identify and mitigate arc flash hazards in electrical equipment.

Consider solutions such as

- Remote racking equipment &

- Arc limiting fuses,

which can help keep both personnel and property safe.

Optimize Electrical Systems & Controls

Determine the appropriate degree of personal protective equipment (PPE) for the flash hazard category and ensure personnel are adequately outfitted. Redesign the equipment & processes to maximize engineering controls that avoid and mitigate risk.

Adjust the settings for circuit breakers & energy distribution systems as needed, and replace high-risk electrical components with devices that reduce incident energy.

Increase Safety Training & Risk Awareness

In addition to being regulated by regulatory agencies such as OSHA, proper safety training assures that employees understand the consequences of being negligent and always follow proper safety protocols.

Not only will this allow them to remain safe in the case of an arc flash, but it will also help them learn how to reduce the danger.

OSHA is one of several national agencies that enforce workplace safety rules, including arc flash protection. These standards protect workers from the electrical hazards and outline workplace safety measures.

Some of these regulations protect workers against fires and electrical arcs. Employers must examine a workplace for flame & electric-arc dangers, estimate arc heat energy, and guarantee personnel wear non-melting protective equipment under 29 CFR 1910.269.

29 CFR 1910.333 prioritizes electrical safety in the workplace. Structures should be de-energized before employees use them. The NFPA 70E Standard, which establishes a facility’s minimum arc flash safety criteria, enforces this OSHA standard.

Develop & Implement a Strict Safety Program

Arc flash hazard studies help to identify the risks, boundaries, and appropriate PPE for electrical safety. Ensure that suitable electrical regulations

Work processes are documented, communicated to all essential staff, and rigidly enforced.

Also, develop a preventative maintenance schedule for electrical materials/equipment, and ensure that only competent and properly trained individuals with the necessary tools and PPE are permitted to work on electric systems.

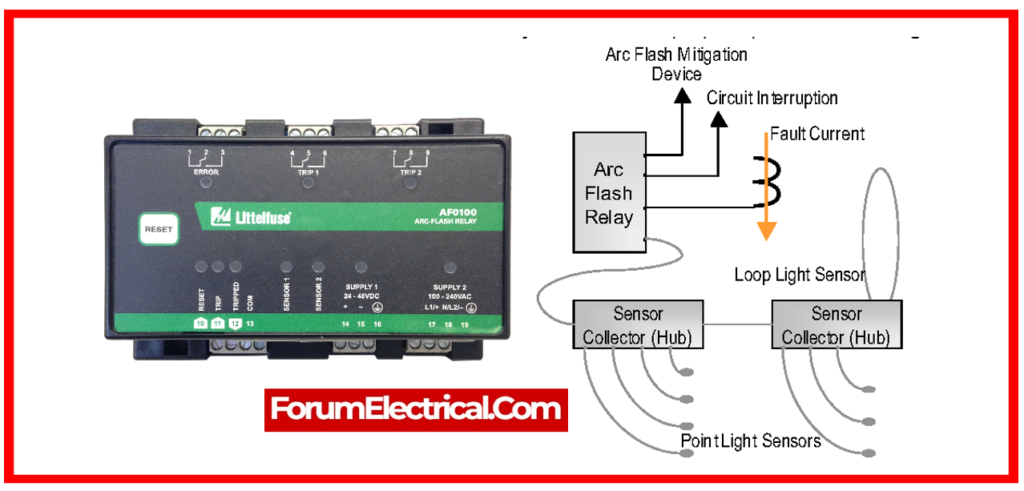

Arc-Flash Relay

Arc-flash relays are microprocessor-based devices which utilize optical sensors to detect the initiation of a flash.

The sensors have been carefully positioned in various cubicles and drawers within the switchboard. Installing an arc flash relay to detect developing arc flashes quickly minimizes total clearing time & the amount of energy released by an arcing fault, resulting in less equipment damage and fewer and less serious injuries to adjacent individuals.

Importance of Arc-Flash Relay

- Arc-flash relays are an essential component in any electrical cabinet because they limit the amount of incident energy in system.

- An arc flash relay can reduce the severity of an arc flash and protect important assets and workers, but cannot avoid it entirely.

- An arc flash relay is a critical component of an arc flash protection system that can reduce damage & save money, as well as lives.

Energy Release in Arc Flash

A phase-to-phase fault in a 480-volt system having 20,000 amps of fault current generates 9,600,000 (W) watts of power.

If there is no arc protection & the fault lasts 200 milliseconds(ms) before the overcurrent protection clears it, 2 megajoules of energy are released, which is about equivalent to a stick of dynamite.

Energy Formula for Arc Flash

The energy formula for arc flashes is:

Energy = Voltage X Current X Time

It is measured in Joules.

For a specific system’s voltage, two factors may be modified to lower arc flash energy:

- Time and

- Current

To quickly detect an electric arc flash, use an arc flash relay such as the PGR-8800 or AF0500.

An arc flash relay causes the linked circuit breaker used to trip at its rapid speed, bypassing any inverse-time delays.

Current can be decreased by utilizing current-limiting fuses or, for phase-to-ground faults, high-resistance grounding.

What is the Arc Flash Duration?

IEEE 1584 defines arc duration, also known as clearing time, as the entire time from the start of a given overcurrent and the last interruption of the circuit at the rated voltage.

What is an Arc Blast?

The arc blast is a pressure wave that occurs following an arc fault. These can be strong enough to knock a technician to the ground (or) cause more equipment damage. Arc blasts might impair your hearing and mental processes. The blast may additionally cause loose equipment, tools, machinery, and debris to propagate around, causing additional damage or injuries.

Difference between Arc Flash and Arc Blast

Arc Flash vs Arc Blast

| Arc Flash | Arc Blast |

| “Arc flash” is a term that describes the energy emitted by an electrical arc. The energy emits high heat & light, which may result in burns. | Arc blast is the pressure wave generated by an arc flash, which can cause a wide range of damage to structures, equipment, and adjacent workers. |

Types of Arc Flash

There are 4 types of arc flash:

- Open air arc flash

- Arc-in-a-box flash

- Ejected arc flash

- Tracking arc flash

1). Open Air Arc Flash

An open-air arc flash, commonly referred to as an arc flash incident, is a potentially hazardous electrical phenomena that happens when an electric current passes through the air between conductors (or) from a conductor to ground. This can occur owing to a multitude of reasons, including

- Equipment failure,

- Insulation breakdown, or

- Inadvertent contact.

During an arc flash, electrical energy ionizes the air, resulting in a conductive path with extremely high temperatures, intense light, pressure waves, and sound.

These incidents have the potential to seriously injure or kill surrounding individuals, as well as destroy equipment and infrastructure.

2). Arc-in-a-box Flash

The term “arc-in-a-box” refers to a situation in which an arc flash happens inside a limited space or enclosure, such as a switchgear cabinet or electrical panel.

When an arc flash occurs in such a restricted place, the consequences can be especially dangerous since the restricted environment magnifies the arc’s pressure and heat impacts.

3). Ejected Arc Flash

An “ejected arc flash” is an arc flash incidence in which material (or) debris is forcefully ejected from the equipment during the occurrence.

An arc flash is a quick release of energy induced by an electrical failure, which usually results in an explosion of light & heat.

When this occurs within an enclosure or near electrical equipment, the extreme heat can melt the surrounding materials, causing them to expand quickly and potentially eject them from the apparatus.

Molten metal, insulation, & other debris from the equipment may be ejected. This material release can represent a major risk to nearby personnel, resulting in burns, injuries, and equipment damage.

To reduce the risks connected with ejected arc flashes, suitable safety precautions should be taken, such as wearing personal protective equipment (PPE), maintaining equipment properly, and adhering to safety standards and regulations. Furthermore, technical measures such as equipment enclosures & barriers can help limit arc flash accidents and reduce the risk of ejected material causing harm.

4). Tracking Arc Flash

Tracking arc flash, additionally referred to as arc tracking (or) carbon tracking, is a phenomenon in electrical systems in which an unintentional electrical arc creates a conductive route down the surface of an insulating substance. This conductive route, which is frequently made of carbonized material, can result in electrical failures, equipment damage, and potentially hazardous scenarios such as electrical fires (or) explosions.

Carbonization: As the arc moves across the surface, it may leave a trace of carbonized material, increasing the path’s conductivity. This carbonization process may compound the situation and result in more severe electrical problems.

Causes: Causes of tracking arc flash include ambient pollutants including dust, moisture, and conducting particles, in addition to mechanical damage to insulating materials.

Risk: Arc flash detection poses major dangers to electrical systems & worker safety. It can cause equipment damage, power outages, and, in severe situations, electrical fires or explosions.

Furthermore, the existence of tracking arcs suggests fundamental flaws with the electrical system that must be rectified to avoid future difficulties.

Prevention: Preventive strategies for reducing tracking arc flash include regular examination and repair of electrical components to identify & address probable sources of insulation failure. Furthermore, good electrical system design and installation, as well as the use of suitable insulation materials, may assist in limit the risk of tracking arc flash.

What is the minimum voltage for Arc Flash?

Arc flash occurrences that ignite clothing are extremely unlikely in systems operating at a minimum of 208 volts phase to phase (120V to ground) and powered by less than a 125 kVA transformer, as 120V (volts) doesn’t provide enough potential to cause an arc flash hazard.

What is Arc Flash Testing?

Arc flash testing assists in identifying the specific hazards and risks connected with electrical equipment. Testing may assist identify the likelihood & severity of an arc flash incident, as well as establish suitable safety measures to limit the danger.

Comparison of Arc Flash Standard

| NFPA 70E-2000 | IEEE 1584-2002 | |

| Voltage Range | 208 V-600 V | 208-15 kV (Empirical) 15 kV+ (Lee Method) |

| Current Range | 0.7 kA-106 KA | 16 kA-50 kA |

| Arc Duration Range | No limit | No limit |

| Installations | Open Air & Cubic Box | Open Air & Cubic Box & Cable Bus |

| Working Distance | 18 inches + | 18 inches + |

| Measurement Unit | Cal/cm2 (or) J/cm2 | Cal/cm2 (or) J/cm2 |

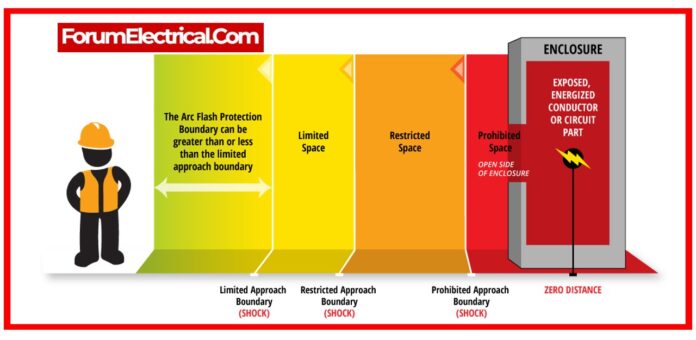

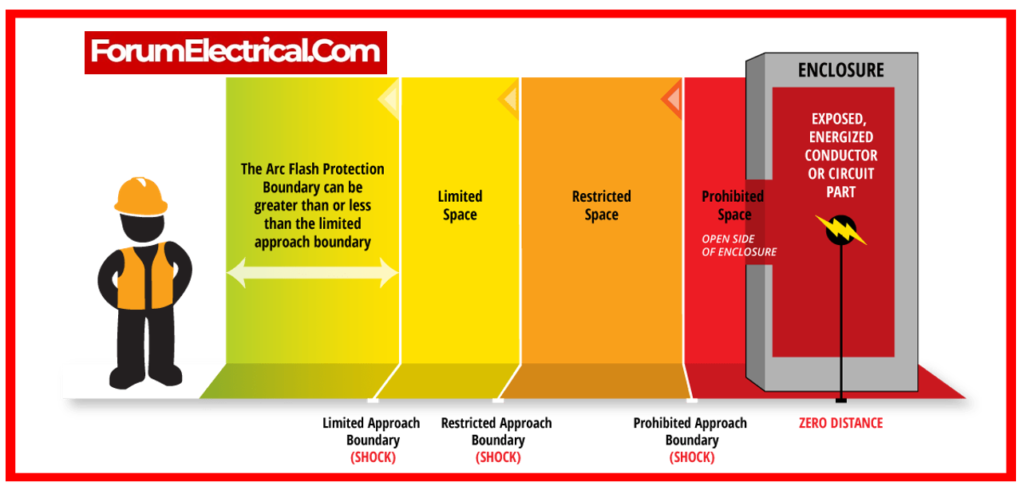

Arc Flash Boundary

The potential arc flash hazard determines the arc flash boundary, which is estimated as 1.2 calories/cm2 of incident energy. That is the distance at which a worker without the proper amount of personal protective equipment (PPE) could receive second-degree burns.

Arc Flash Analysis

Arc flash analysis or research is useful for identifying potential electrical dangers in the facility that can cause fires, explosions that leads to injuries, fatalities, & considerable downtime.