Electrical current provides a major and widespread occupational threat to workers. Many workers are unaware of the possible electrical hazards in their work environment, which renders them more vulnerable to electrocution. There are 4 major types of electrical injuries:

- Electrocution (death),

- Electric shock,

- Burns, and

- Falls induced by contact with electrical energy.

The Occupational Safety and Health Administration (OSHA) establishes electrical safety standards for general industry in 29 CFR 1910.302 through 1910.399. NFPA 70, National Electrical Code (NEC), 2014 Edition, and NFPA 70E.

The National Fire Protection Association’s (NFPA) Standard for Electrical Safety in the Workplace, 2015 Edition, specifies safety rules for electrical installations and working with electrical equipment.

This checklist can assist in identifying common electrical hazards & best practices, but it should not be utilized as a substitute for OSHA or NFPA code and standard compliance.

Any question marked “No” should be properly investigated & corrective action taken.

An appropriate electrical self-inspection will:

- Identify electrical wiring & components that can have deteriorated over time.

- Determine whether the electrical circuits are overloaded.

- Determine if there is a lack of earthing.

- Identify any faulty wiring or other errors done by uncertified electricians.

- Identify large fuses or breakers that could cause an electrical fire.

- Identify any potential electric shock hazards.

What are the activities involved in an inspection of an electric circuit?

In the process of inspecting an electric circuit, it includes an evaluation of the integrity of the earthing and bonding, as well as a visual inspection to look for breaks, fractures, or symptoms of overheating.

Additionally, it includes a dead test of specific circuits. Until the next inspection, the primary objective of this is to make sure that the electrical installations are secure enough to be used.

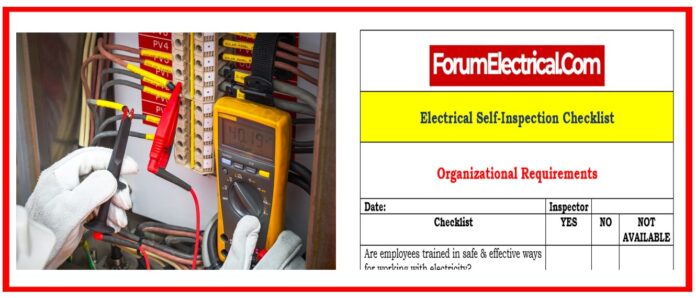

Electrical Self-Inspection Checklist

1). General Safety Measures

- Look for physical indications of damage to electrical outlets, switches, & wiring.

- Make sure the electrical panels are conveniently accessible and not obscured.

- Check ground fault circuit interrupters (GFCIs) & arc fault circuit interrupters (AFCIs) for correct operation.

2). Electrical Panels & Circuit Breakers

- Check electrical panels for symptoms of overheating, corrosion, and loose connections.

- Inspect circuit breakers for tripping and ensure they are properly labeled.

- Check sure circuit breakers are not overloaded & are the correct size for the circuits they protect.

3). Outlet and Switches

- Check all outlets & switches for appropriate operation.

- Check for symptoms of overheating, dis-coloration, or damage near outlets and switches.

- Make sure outlets are correctly grounded & have covers in place.

4). Wires and Cables

- Inspect visible wire and cables for evidence of wear, breakage, or incorrect installation.

- Verify for exposed wires, frayed insulation, and cable pinch spots.

- Ensure that the wiring is securely fastened and not subjected to severe bending or tension.

5). Light Fixtures

- Check lighting fixtures for the loose connections, damaged components, and symptoms of overheating.

- Check that the bulbs are the appropriate wattage & type for each fixture.

- Check for adequate grounding & insulation in the light fixtures.

6). Appliances & Equipment

- Check appliances & electrical equipment to ensure good operation & safety features.

- Inspect wires & plugs for damage (or) wear & tear.

- Check that appliances are not overloaded & are utilized in accordance with the manufacturer’s recommendations.

7). Outdoor Electrical Systems

- Examine outdoor outlets, lighting, & electrical equipment for evidence of weather damage (or) corrosion.

- Outdoor electrical systems should be adequately grounded & protected from the elements.

- Check that exterior wiring and cables are properly installed and maintained.

Purpose of Electrical Self-Inspection Checklists

The key objectives of performing regular electrical self-inspection checklists include:

- Identify potential safety dangers: Self-inspections help you to detect problems with wiring, outlets, appliances, and other components before they become serious safety issues that might result in electric shock, fires, (or) equipment damage.

- Prevent electrical fires: Faulty electrical equipment (or) wiring is the major cause of residential fires. Early detection of electrical problems can help to avoid a disastrous and dangerous fire.

- Fix problems prior to cause damage: Minor electrical issues, such as a defective outlet or old wiring, can eventually lead to larger problems, such as power surges that harm electronics and appliances.

- Improve electrical safety & compliance: Schedule regular inspections to ensure that your home’s electrical systems satisfy local safety codes and standards for outlet spacing, GFCI outlets near water sources, wire gauges, tamper-resistant outlets, and so on. This increases the residence’s safety.

- Increase the longevity of electrical system: Regularly maintaining the electrical system via checks & repairs extends the life of the infrastructure & delays the need for major upgrades or complete rewiring projects.

- Establish maintenance routines: Similar to how with other maintenance work, getting into the practice of inspecting the electrical systems on a regular basis helps you develop solid procedures for caring of this major investment.

In general, electrical inspection checklists are a proactive method to maintain safety, decrease fire risk, correct faults on time, and ultimately get the maximum efficiency out of the electrical system.

What are the advantages of electrical self-inspection?

Regular electrical inspections by experienced electricians provide several major benefits to consumers. Here are 5 key advantages:

- Enhanced safety

- Preventing electrical dangers and fire circumstances

- Early problem detection

- Adherence to national & local electrical safety codes

- Avoid fires and cut down on potential dangers.

- Take precautions to avoid electric shocks & electrocution.

- Locate and correct errors as soon as possible.

- This can cut down on the costs of repairs in the future.

- Enhance the quality of safety for the organization.

- Enhance the lifespan of the electrical supply system