- What is a Circuit Breaker?

- Working Principle of Circuit Breaker

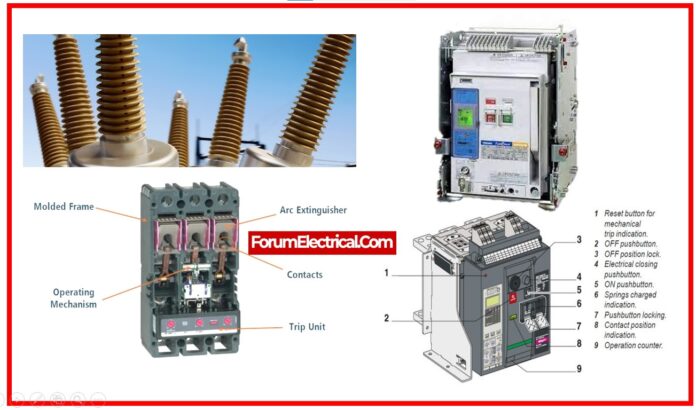

- 5 Fundamental Components of a Circuit Breaker

- How does Circuit Breakers Work?

- Circuit Breaker Operation

- Difference Between Fuses and Circuit Breakers

- Fuses vs Circuit Breakers

- Circuit Breakers in Substation

- Circuit Breakers in Power System

- Types of Circuit Breaker

- Advantages of Circuit Breaker

- Disadvantages of Circuit Breaker

- Applications of Circuit Breaker

- Frequently Asked Questions (FAQs)

What is a Circuit Breaker?

A circuit breaker is a type of electrical switch that protects an electrical circuit from damage due to overcurrent/overload (or) short circuit. Its primary function is to stop current flow when protective relays identify a fault.

A circuit breaker is a switching mechanism used to control and protect an electrical power system that can be managed manually or automatically. It is made up of two major contacts: one fixed and one movable.

Because the contacts are generally closed, current can pass through the circuit. When a defect occurs, including a short circuit (or) an overload, a device separates the contacts, releasing stored potential energy. This mechanism can be spring-powered, pneumatic, hydraulic, (or) magnetic in function.

The separation of contacts results in the formation of an arc, that is a highly ionized & conducting plasma. If not extinguished soon, the arc can cause damage to the contacts & the surrounding equipment.

As a result, circuit breakers use a wide range of techniques to cool down the arc, including cooling, compressing, and replacing the ionized medium with the fresh gas. The arc quenching medium selected is determined by the circuit breakers voltage and current rating.

Overcurrent, short circuits, and overload destroy electrical circuits; therefore, circuit breakers protect them. After a fault occurs, they prevent the flow of current and restore it after the fault is cleared.

Compared to a fuse, which must be replaced after each operation, a circuit breaker can be reset & utilized several times.

While the current is immediately cut off, engineers must still design electrical systems that are capable of withstanding the maximum available fault current that happens during a failure condition.

Circuit breakers have an importance for electrical system safety and dependability. Circuit breakers may protect individuals from electrical shocks if a failure emerges.

Working Principle of Circuit Breaker

A circuit breaker is composed of electrodes that serve as both

- Fixed contacts &

- Moveable contacts.

Under normal functioning settings, these contacts remain closed & will not open autonomously (automatically) unless the system malfunctions. These contacts can be opened manually or remotely.

When a failure occurs in any component of the system, the trip coils of the circuit breaker get energized, drawing the moveable contacts apart & opening the circuit.

When the contacts of the circuit breaker get separated owing to a failure, an arc is created. Arc formation causes current interruptions to be delayed & generates a lot of heat, that might damage the system (or) the circuit breaker.

As a result, the primary responsibility in a circuit breaker is to extinguish the arc as soon as feasible so that the heat emitted by it does not reach a dangerous level.

5 Fundamental Components of a Circuit Breaker

Tripping (or) Protective Mechanism

Tripping (or) Protective Mechanism also referred to as the trip unit, this activates the working mechanism in the event of an electrical malfunction.

Operating Mechanism

Operating mechanism that opens or closes the breaker to perform its protective function.

Molded Frame

Most breakers’ outer protective & supportive case. It provides insulation for the additional component of the breaker.

Arc Chutes

Arc Chutes located near the contacts, chutes minimize damage and, in most cases, heat from interfering with the performance of the circuit breaker and move apart when a fault occurs.

Contacts

There are 3 types of contacts that are employed to ensure efficient airflow inside the breaker:

- Arcing contacts,

- Auxiliary contacts, and

- Main contacts.

How does Circuit Breakers Work?

A circuit breaker works on a high level like following steps:

Step-1: The circuit breaker identifies a fault condition in the electrical system, which includes an overload (or) a short circuit.

Step-2: When a fault is identified, the circuit breaker initiates a device that causes the discharge of stored potential energy.

Step-3: This energy then separates the circuit breakers two major contacts: a fixed contact & a moving contact.

Step-4: When contacts separate, a highly conductive & ionized plasma referred to as an arc is formed.

Step-5: The circuit breaker extinguishes or quenches the arc by cooling, compressing, (or) replacing the ionization medium with fresh gas.

Step-6: This technique stops the flow of current, preventing any harm caused by the fault state.

Step-7: Once the fault has been cleared, the circuit breaker can be reset manually or automatically, allowing current to flow once more.

Step-8: Resetting the breaker reconnects the fixed and movable contacts, restoring current flow across the circuit.

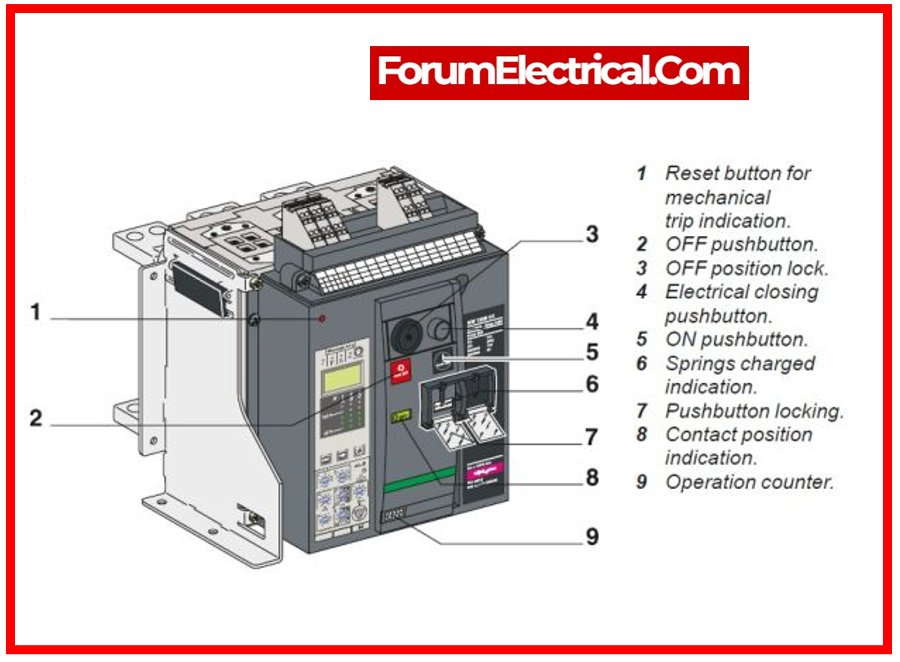

Circuit Breaker Operation

A circuit breaker operates by interrupting an electric current in a circuit. A circuit breaker contains both fixed and moveable contacts.

These two contacts are physically linked to each other in the ordinary “ON” position on the circuit breaker due to mechanical pressure put on the moving contacts.

The potential energy stored in the operating mechanism is released when the circuit breaker gets a switching signal. This potential energy can be kept in a variety of ways, including metal spring deformation, compressed air, & hydraulic pressure.

During operation, potential energy, irrespective of its source, needs to be released. This energy release allows the moving contact to proceed swiftly.

Following an operation cycle, the entire stored energy released, & the potential energy remains in the operating mechanism through a spring charging motor, an air compressor, (or) any other method.

A circuit breaker’s operation, however, is not purely mechanical; electrical features need to be addressed.

High rated (or) fault power must be handled by the circuit breaker. As a result, there is always potentially excessive arcing among moving and immovable contacts during operation.

If the dielectric strength within the current-carrying contacts rapidly increases at every alternating current zero crossing, the arc can be safely extinguished.

Compressing the ionized arcing medium (which promotes deionization), cooling the arcing medium (which enhances arcing path resistance), & replacing the ionizing arcing medium with fresh gasses are all strategies for increasing dielectric strength. As an outcome, arc quenching is a vital component of circuit breaker operation.

Difference Between Fuses and Circuit Breakers

Fuses vs Circuit Breakers

| Fuses | Circuit Breakers |

| It must be restored after interrupting an overcurrent occurring. | After interrupt an overcurrent event, it may be reset. |

| Has a lower initial cost | Has a higher start-up cost |

| There is no need for maintenance. | It must be maintained |

| There is no provision for optional protective features. | Optional safety features (for example, ground fault) |

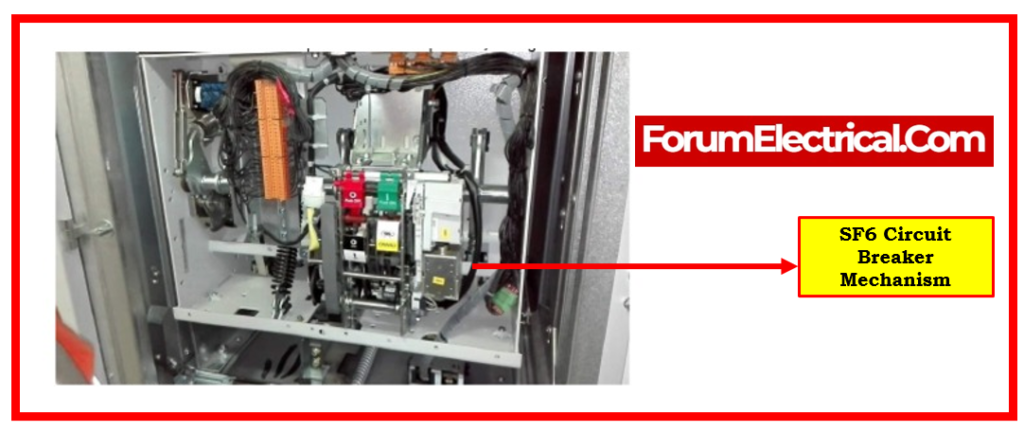

Circuit Breakers in Substation

Substations are essential components of the electrical system that carry out a number of essential functions, including converting voltage from high to low or the other way around.

In order to maintain safe and effective operation, circuit breakers are essential components of substations. They are in charge of

- Fault clearing,

- Overcurrent protection, and

- Maintenance equipment isolation.

Circuit breakers are usually arranged in a substation such that selective tripping is possible.

This implies that in the event of a fault, the remainder of the network will remain unaffected and only the circuit breakers linked to the problematic area of the network will open.

Substations frequently employ high-voltage circuit breakers, such as SF6 circuit breakers, because of their dependability, minimal maintenance needs, and superior arc extinguishing capabilities.

Circuit breakers comply with various standards established by various organizations. Here is a list of a few of the most regularly used circuit breaker standards:

UL 489: A standard developed by Underwriters Laboratories for molded-case circuit breakers and circuit breaker enclosures.

IEC 60947: IEC 60947 is a standard developed by the International Electrotechnical Commission for low-voltage switchgear and control gear and switchgear.

ANSI/IEEE C37: Standards for high-voltage circuit breakers developed by the American National Standards Institute (ANSI) and the Institute of Electrical and Electronics Engineers (IEEE).

NEMA AB 4: NEMA AB 4 is the National Electrical Manufacturers Association standard for molded-case circuit breakers and switches.

IEC 60898: International standard for overcurrent protection circuit breakers for residential and similar applications.

The scope of these standards varies, specifying requirements for performance, safety, testing processes, construction, and several other characteristics of circuit breakers for various voltage levels and applications. Depending on their legislative requirements and industrial norms, different regions & countries may adopt unique standards or a combination of various standards.

Circuit Breakers in Power System

Circuit breakers play a vital role in power systems by executing essential protective operations.

They safeguard the power system against faults and prevent damage to

- Transformers,

- Transmission lines,

- Solar cells,

- PLC, and

- Other electrical equipment

by interrupting the flow of abnormal currents.

Circuit breakers perform a complicated function in power systems, involving consumer end utility areas, transmission & distribution networks, & power generation plants.

Circuit breakers secure generators & transformers against faults in power facilities. Faulty segments are isolated in transmission & distribution networks to impede the propagation of the fault throughout the entire system.

In power systems, the priority for circuit breakers is determined by the voltage level, current rating, anticipated fault type and frequency, environmental conditions, & maintenance requirements.

Types of Circuit Breaker

Circuit breakers can be broadly categorized into 2 categories:

- AC Circuit Breaker

- DC Circuit Breaker

AC Circuit Breaker

Types of AC circuit breakers vary according to their respective categories:

Based on Voltage

- Ultra-High Circuit Breaker,

- High Circuit Breaker.

- Medium Circuit Breaker, and

- Low Circuit Breaker.

Based on Location

- Indoor Circuit Breaker,

- Outdoor Circuit Breaker.

- Based on External Design:

- Dead Tank Circuit Breaker,

- Live Tank Circuit Breaker.

Based on Interrupting Medium

- Air Blast Circuit Breaker,

- Oil Circuit Breaker,

- Air Circuit Breaker,

- Vacuum Circuit Breaker,

- SF6 Circuit Breaker.

DC Circuit Breaker

The HVDC (High Voltage Direct Current) circuit breaker is one kind of DC circuit breaker that is similar to the AC circuit breaker.

Advantages of Circuit Breaker

- It protects against damage resulting from a high flow of current.

- It is more reliable.

- A greater increase in dielectric strength results in a reduced contact gap.

- Due to its switch-controlled nature, it is resetting-capable.

- It is appropriate for frequent operations due to its low arcing time and energy.

- It is extremely sensitive during operation.

- It serves as a protection monitor for both HT & LT line systems.

- An entirely eradicated hazard is fire.

Disadvantages of Circuit Breaker

- They are more complex and costly than fuses.

- Consistent testing and maintenance are necessary for ensuring their optimal operation.

- They might malfunction as a result of mechanical or electrical flaws.

- It exhibits sensitivity to voltage fluctuations.

- In comparison, arc extinguishers possess inferior properties.

- Switching operations may result in voltage surges (or) transients being induced.

Applications of Circuit Breaker

- Circuit breakers are utilized in residential, commercial, and industrial settings to transfer various types of loads.

- In order to protect electrical equipment in residential and commercial spaces against fault current, overcurrent, short-circuit, & fire, circuit breakers function as switchgear.

- Circuit breakers identify applications in motors and auxiliary circuits.

Frequently Asked Questions (FAQs)

1). What is the working principle of a circuit breaker?

In electrical distribution systems, the circuit breaker is an electromechanical device and its function is to protect electrical installations. It functions by disrupting the flow of electricity when it surpasses its intended thresholds, thereby preventing the need for energy to reach the loads and preventing circuit damage.

2). What is the main principle circuit breaker?

The two primary wires that lead to the hot busbars are controlled by the primary circuit breaker. The branch breakers are protected from 240 volts of energy until the primary circuit breaker trips. The house’s electrical systems will go shut off as soon as the primary breaker trips.

3). What is the purpose of circuit breakers?

Circuit breakers serve two different purposes:

- Performing maintenance by turning the equipment on and off while it is normally operating.

- Protecting equipment by switching in the event of unusual conditions like earthing or short circuits.