Abstract

In today’s environment, power saving systems provide a wide range of objectives. We are using a remote control to operate an electronic D.C. motor speed regulator.

This regulator maintains the motor’s programmed speed constant. This “Wireless Dc Motor Speed Control” allows you to regulate the speed variation caused by overload, line voltage variations, overvoltage, surge difficulties, and other factors, and keep the speed constant.

This particular model can be utilized up to a 1 HP D.C. motor.

Existing System

Nowadays, there are numerous high-quality motor speed controls on available for purchase.

However, the costs are relatively significant. A low-cost, high-performance speed control will be very marketable, particularly for small mobility applications.

Wireless networking, on the other end, has the advantage of being less expensive and having less environmental restrictions.

Proposed System

The wireless remote controller is easy to understand: start, stop, accelerate, and decelerate.

The speed control uses a 12 V battery to control currents ranging from 0 to 50 A.

The controller is highly efficient for motor loads ranging from 50 to 150 watts.

It should produce the nominal power continuously & be able to withstand minor overloads for a limited length of time.

For severe overloading, it should safeguard the motor from harm for a few seconds before shutting down and requesting a reset from the user.

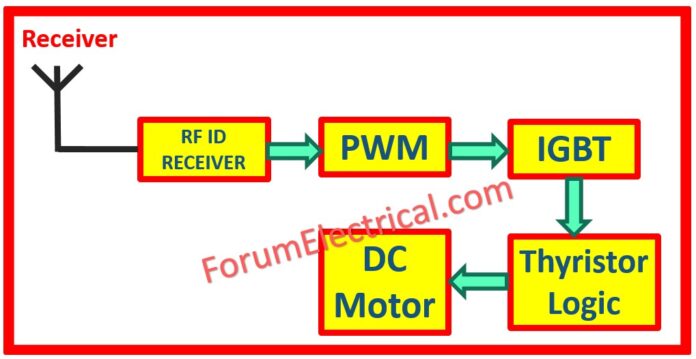

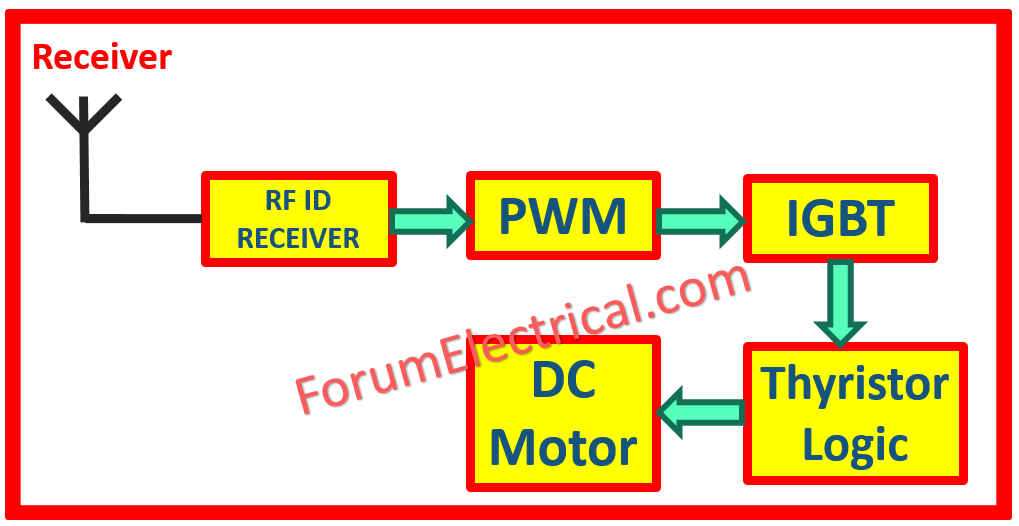

Block Diagram Detail

Rf Module

A radio frequency module (RF module) is a very small electrical circuit that transmits and/or receives radio signals using one of several carrier frequencies.

RF modules are commonly utilized in electronic design due to the difficulties of developing radio circuits.

Good electronic radio design is extremely difficult due to the sensitivity of radio circuits & the accuracy of components & layouts necessary for operation at a certain frequency.

Design engineers will create a circuit for an application that requires radio communication & then “drop in” a radio module rather than attempting a discrete design, which saves time and money on development.

IGBT

The insulated-gate bipolar transistor (IGBT) is a 3-terminal power semiconductor device that is largely employed as an electronic switch in modern systems. It is known for its high efficiency and quick switching.

It is used to switch electricity in a variety of modern equipment, including

- Variable Frequency Drives (VFDs),

- Electric Automobiles,

- Trains,

- Variable Speed Refrigerators,

- Air Conditioners, and

- Stereo Systems equipped with switching amplifiers.

Because it is meant to turn on and off quickly, amplifiers that employ it frequently generate complicated waveforms using

- Pulse width modulation &

- Low-pass filters.

In switching applications, current devices have pulse repetition rates well into the ultrasonic range frequencies that are at least ten times the device’s maximum audio frequency when employed as an analog audio amplifier.

Thyristor

The thyristor is a 4-layered, three-terminal semiconductor device in which each layer alternates between N-type and P-type material, such as P-N-P-N.

The principal terminals, called anode & cathode, are located on all four layers. The control terminal, or gate, is linked to p-type material near the cathode.

A variation known as a SCS (Silicon Controlled Switch) connects all four levels to terminals.

A thyristor operates as a pair of tightly connected bipolar junction transistors configured to generate a self-latching action.

Pulse Width Modulation

Pulse-width modulation (PWM), sometimes known as pulse-duration modulation (PDM), is a type of modulation that adapts the width of a pulse, or its duration, to modulator signal information.

Despite of this modulation technique can be utilized to encode information for transmission, its primary application is to modulate the power sent to electrical devices, particularly inertial loads like motors.

The average voltage (and current) provided to the load is adjusted by rapidly turning the supply-load switch on and off. The power provided to the load increases as the switch is on for a longer amount of time than it is off.

The PWM switching frequency must be far faster than what would effect the load, which is the equipment that consumes power.

Typically, switching occurs many times per minute in an electric stove, 120 Hz in a lamp dimmer, a few kilohertz (kHz) to tens of kHz for a motor drive, and far into the 10 or 100 of kHz in audio amplifiers & computer power supplies.

DC Motor

A DC motor is a mechanically coupled electric motor that runs on direct current (DC). The stator is motionless, thus the commentator switches the current in rotor to be stationary as well.

This is way the relative angle across the stator & rotor magnetic flux is kept near 90 degrees, resulting in the highest torque.

DC motors contain a spinning armature winding (which induces a voltage) but no rotating armature magnetic field, as well as a static field winding (which generates the main magnetic flux) (or) permanent magnet.

Different connections between the field & armature winding provide varying intrinsic speed/torque regulation properties. A DC motor’s speed can be changed by adjusting the voltage provided to the armature or the field current.

The use of variable resistance in the armature or field circuit enabled speed control. Modern DC motors are often controlled by power electronics systems known as DC drives.

The use of direct current (DC) motors to power machinery reduced the requirement for local steam (or) internal combustion engines and line shaft drive systems.

DC motors may run directly on rechargeable batteries, providing motive power for the initial electric cars.

DC motors are still used today in a variety of applications, ranging from toys and disk drives to steel rolling mills & paper presses.

Advantages

Advantages include

- Low time consumption,

- High level of accuracy, and

- Quick switchover.

Applications

- For industrial use

- Turn agricultural motor ON/OFF.