- Introduction to the three-phase induction motor’s soft starter

- Principle of soft starter for a three-phase induction motor utilising the PIC microcontroller

- Circuit diagram for a three-phase induction motor’s soft starter

- Components of soft starter for a three-phase induction motor utilising the PIC microcontroller

- Advantages of Soft starter for 3 phase induction motor using microcontroller

- Applications of Soft starter for 3 phase induction motor using microcontroller

- Conclusion

This post uses a PIC microcontroller to provide a soft starter for a three-phase induction motor. In this post, a microcontroller is used to construct a soft starter for a three-phase induction motor.

A three-phase induction motor can start smoothly using a soft starter, an electrical device. Every induction motor starts with a high current draw that exceeds the three-phase induction motor’s rated capability.

Inrush current is another term for the high current. The motor windings may potentially suffer long-term harm from this inrush current. Therefore, a device that can regulate the three-phase induction motor’s high starting current is required.

Typically, smooth starters (or) soft starters are used to manage the motor’s inrush current when it first starts to function.

So, let’s start by introducing the smooth starter and learn how it works.

Introduction to the three-phase induction motor’s soft starter

A huge amount of current, known as inrush current, is drawn when a three-phase induction motor is first turned on.

A three-phase induction motor likewise accomplishes its maximum speed quickly or instantaneously. Instantaneous acceleration to full speed creates mechanical vibrations in the motor as well as electrical stress on the motor windings, which might lead to winding damage.

Thus, it is necessary to use soft starters or three-phase smooth starters for induction motors to prevent this impact.

And also need to regulate the speed of the induction motor at the starting so that the motor speed should only develop gradually in order to prevent this instantaneously speed-increasing impact of three phase induction motors.

The three-phase induction motor’s gradually rise in speed likewise imposes a gradual increase in current.

Thus, the motor is protected against mechanical jerks and the possibility of burning motor windings by the progressive rise in speed and current.

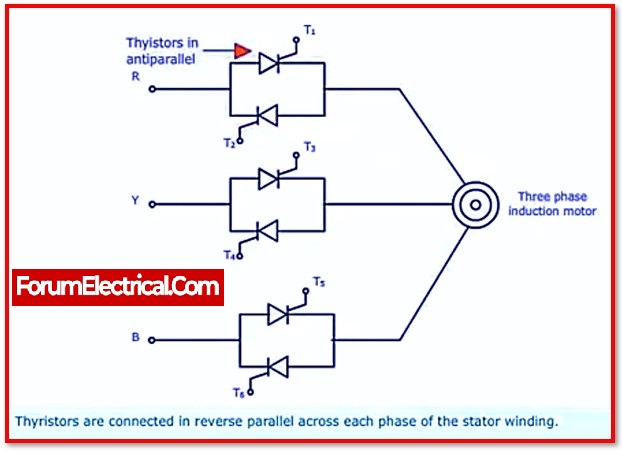

Principle of soft starter for a three-phase induction motor utilising the PIC microcontroller

Here PIC microcontroller is utilised to supply thyristor-controlled voltage to a three-phase induction motor.

Thyristors are fired with a complete delay at first, then their firing angles start to progressively decrease and will do so going forward. When the thyristor firing angle reaches zero, the induction motor’s three phases all experience full voltage.

In simple terms, a three-phase induction motor will get a low voltage at first, and then it will gradually increase. Full voltage will eventually be seen across the motor windings.

It will provide a smooth, inrush-current-free start for the three-phase induction motor. Therefore, the motor starts off slowly before gradually increasing to its maximum rated speed.

The implementation of a smooth starter for a three-phase induction motor is simple using pic microcontroller.

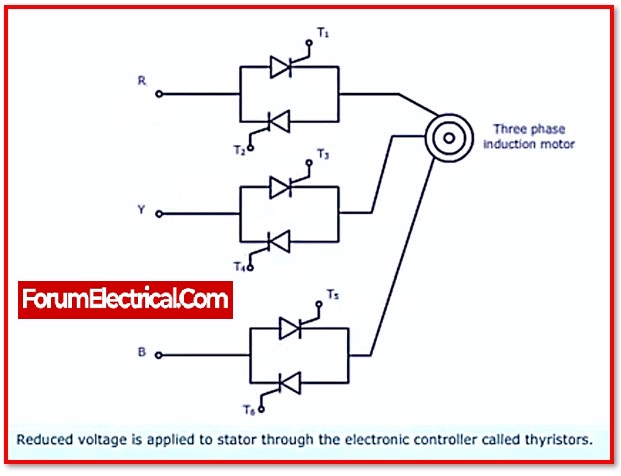

Circuit diagram for a three-phase induction motor’s soft starter

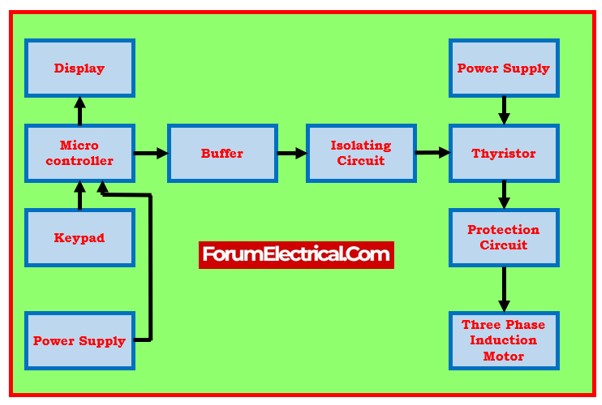

The circuit schematic for a three-phase induction motor’s smoother start utilising a PIC microcontroller is presented below. It is made up of three zero crossing detection circuits, one for each phase of the three-phase power supply, and a PIC microcontroller that controls the firing angle of the thyristors via an optical isolator.

Components of soft starter for a three-phase induction motor utilising the PIC microcontroller

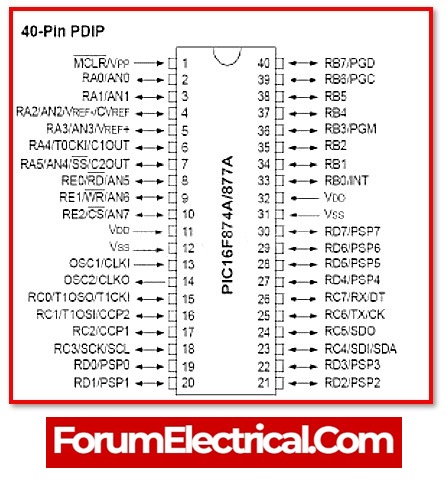

a). PIC Microcontroller

Link :

1).https://microcontrollerslab.com/soft-starter-induction-motor-using-microcontroller/

The PIC (Peripheral Interface Controller) microcontroller, which is always in communication with all of the monitoring equipment in the system, is a key component of the system. There are many different kinds of microcontrollers available on the market, and they are simple to find with 40 pins. This controller is also simpler to programme and code.

b). Buffer and Isolating Circuit

The isolation between two circuits is provided by an opto isolator. In other words, the PIC circuit and the thyristor circuit are not electrically connected. Without requiring an electrical connection, it joins two circuits.

A buffer is an integrated circuit that has a unity gain amplifier. Its purpose is to provide enough drive capacity to transfer signals (or) data bits to a following step. In either condition, the buffer provides a suitably strong signal to the next step while safeguarding the output of the supplying device. Some data buffers enable data to flow in both directions and are bi-directional.

c). Power Supply

In this circuit, two power supply are used. one for the motor and one for the PIC circuit.PIC circuit needs a 5V power source to function, and the motor is powered by 230 volts through a thyristor driver.

d). Keypad

- numerals,

- symbols, and

- a full set of alphabetical letters.

e). Display

In situations where LEDs are utilised, LCDs are also used. These applications include the segmental and dot matrix displays of numeric and alphabetic characters. As the display is attached to the controller, it will display the

- Voltage,

- Current,

- Speed, and other information.

f). Protection Circuit

Thyristor drivers are equipped with simple protective circuitry for overload protection, voltage fluctuations, etc. in the form of resistors.

g) .Three Phase Induction Motor

A form of asynchronous AC motor known as an induction motor (IM) power the spinning equipment using electromagnetic induction. Due to the rotor bars with short circuit rings resembling a squirrel cage (hamster wheel), another term that is often used for this kind of motor is squirrel cage motor. In its rotor (spinning component), an electric motor transforms electrical power to mechanical power. Power may be delivered to the rotor in a variety of ways. Unlike an induction motor, which induces this power into the spinning unit, a DC motor supplies this power to the armature directly from a DC source. Because the rotor, which rotates, is the secondary side of the transformer and the stator, which is fixed, is the primary side, an induction motor can be referred to as a spinning transformer. Induction motors are often employed in industrial drives, particularly polyphase induction motors.

Advantages of Soft starter for 3 phase induction motor using microcontroller

- The mechanical stresses on the motor and shaft will be lessened.

- It will increase equipment longevity.

- Motor will use less inrush and starting current.

- It will be a versatile application with many uses.

Applications of Soft starter for 3 phase induction motor using microcontroller

- In milling machines with the dynamic brakes, it will be helpful.

- It will be helpful for pumping in the agricultural sector.

- It is practical for lifts.

- It is beneficial for conveyor systems.

Conclusion

Therefore, the desired outcome of a smooth and dependable motor starting will be accomplished based on all the results. It will regulate starting current and reduce starting current from the motor due to torque. Therefore, it can demonstrate that a motor starts softly by using formulae to compute starting current and torque.