It is the responsibility of this pre-commissioning document, together with other documentation pertaining to inverter commissioning, to ensure that the powerplant inverter and its accessories are able to successfully undergo the commissioning process and start operating.

Maintain these documentations in the appropriate manner.

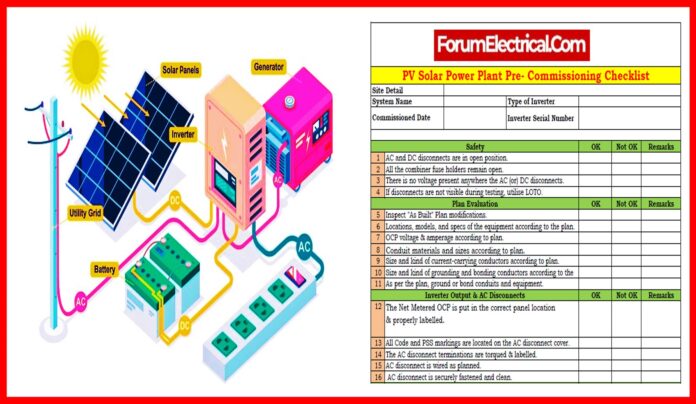

In the pre-commissioning report, all of the parameters that need to be checked during the commissioning process are included.

Before starting operation, the parameters in an inverter must be adjusted to reflect the local grid conditions. Inverters are the core of any solar power system. This is known as commissioning the inverter. If well-equipped, it’s as simple as setting up a new smartphone.

Every installer/solar developer’s major objective would be to generate high-quality power while requiring less maintenance. This can only be accomplished by conducting a pre-commissioning inspection of the plant.

Prior inspection includes

- Correct string sizing,

- Polarity,

- Earthing,

- Protection devices, and

- Grid parameter checks.

In a solar plant, the DC source is the DC power generated by PV arrays, which are created by connecting solar modules in series.

The PV array produces positive and negative cables, which are combined to form a string. The number of threads varies from one to several, depending on the plant capacity.

These strings are used as the DC input for an inverter.

Pre-Commissioning Checklist for Solar Inverter

This checklist is primarily for informational reasons and should not be used to replace the particular instructions provided by the solar inverter manufacturer & qualified installation. Before commencing any pre-commissioning procedures, always review the inverter handbook and take all necessary safety precautions.

General

- Read the inverter instructions and make sure you understand it. To ensure a secure and effective installation and operation, this is very necessary.

- Check that all necessary permits and approvals have been obtained. Make sure that your system doesn’t violate any of the local restrictions.

- It is recommended to avoid commissioning during inclement weather conditions like rain, snow, or strong winds.

- It is important to gather all of the appropriate tools and equipment, which may include a multimeter, an insulation tester, a grounding tester, & personal safety equipment (PPE).

Location and Installation

- Check to see that the mounting and the physical location are accurate. It is imperative that adequate ventilation, accessibility, and compliance with safety laws be maintained.

- Ensure that the inverter is free of any obvious damage. Be on the lookout for any indications of water damage or physical damage.

- Verify that all of the cables are connected and secured in the correct manner. Ensure that the cable diameters and connectors are adequate.

- Verify that the DC & AC disconnect switches are functioning properly. Make sure that they are labeled appropriately and that they perform faultlessly.

- Check that the earthing connections are safe and that they comply with the local standards in order to ensure safety, proper grounding is essential.

Electricity Inspections

- To ensure that the DC input voltage and current are in accordance with the inverter’s specifications & array arrangement, it is necessary to measure them.

- Determine the voltage and frequency of the AC output. Check to see that they meet the standards of the grid.

- Insulation resistance testing should be performed on both DC and AC wires. As a result, this addresses the possibility of insulation failure.

- Make sure there are no ground leakage currents. Check to see if they fall within the permitted range.

Ground Fault Check

Ground fault detection is essential in solar power plants for ensuring safety, preventing equipment damage, and keeping the system running efficiently.

Ground failures happen when an unexpected connection is created between a live conductor & the ground, which can lead to electrical risks and system downtime.

There are several methods for detecting ground faults in a solar power plant:

Ground Fault Detection Devices: Use ground fault detection devices, such as ground fault circuit interrupters (GFCIs) or ground fault protection relays (GFPRs), to monitor electrical circuits and immediately detect ground defects.

Conduct frequent insulation resistance tests to determine the insulation resistance between conductors & ground. A drop in insulation resistance could signify the presence of a ground fault.

Test all grounding conductors to ensure they are correctly connected and intact, reducing the possibility of ground faults.

Perform routine visual inspections of the solar array, inverters, combiner boxes, & other components to look for indicators of physical damage or deterioration that could lead to ground faults.

Implementing an extensive ground fault check method enables solar power plant operators to quickly identify and address possible faults, assuring the system’s safety, dependability, and efficiency.

According to IEC 60364-7-712, solar plant earthing is divided into two key categories:

- DC Side and

- AC Side.

DC Earthing

A system’s installation requires that a lightning arrestor is installed for the entire system, that it is properly linked to a separate earth pit, and that its resistance is less than 10 ohms, according to IEC 62305-3.

The installer must identify and visually verify each component involved, checking for damage or breakage on panels and cables.

The panel-to-panel and panel-to-structure earthing systems must be verified.

The structure earthing is interconnected with a flat earth strip rod and sent to the earth pit.

The design of the earth cable and earth strip is determined by the maximum short circuit current that might occur on the system.

The installation must verify the maximum short circuit current of the PV panels and the PV generator.

The number of earth pits delivered to the system will be determined by the power plant’s capacity and the total area covered by the components involved.

To ensure a properly earthed system, the earth pit resistance should be less than 2 ohms.

An installer should check resistance using an Ohmmeter to ensure that it is less than 2 ohms.

AC Earthing

The grid connection inverter will not output any power if it detects an isolation fault in the PV panels or an earthing problem on the grid side. It will separate from power generation.

The installer has to check the AC voltages across Phase to Phase, Phase to Neutral, and Neutral to Earth, and all of these values must fall within the standards of the respective country.

Cover the conductors with glands to protect them from insects and pests.

In a properly earthed system, the N-E value will be less than 5V.

The inverter body should be earthed to protect the person contacting it.

Check Insulation Resistance of Cables

Punctured wires are another cause of earth leakage. Visually check the AC and DC conductor cables. This may not always be noticeable visually.

Before commissioning, the installer must examine the insulation resistance of the wires with an Insulation Resistance Meter (Ohmmeter).

The pointer will display 0 if there is a short circuit inside the conductor, and infinity if there is an open circuit, i.e., if the cable is cut.

Each cable in the system, including AC & DC carrying conductors, must be tested before connecting to loads. If the system is not earthed & is connected to the loads, the leakage current will pass by the lowest resistance path possible (or) by touching it, causing significant damage to personal safety and the associated equipment. Therefore, earthing is essential.

Setting up the Inverter

- Commissioning of the inverter must follow national grid specifications.

- The manufacturers will determine how each inverter’s user interface is different. The installation handbook will also include instructions on how to initialize and set up the inverter.

- After verifying the input and output, the majority of installers leave the system un-commissioned.

- The inverter functions perfectly, but if it isn’t configured, it will cause a number of problems that will disrupt the production of electricity.

- Every cable and connector need to have a routine inspection.