An electromagnetic static device called a transformer is used to change electrical power from one voltage level to another. The transformer’s winding and core both lose some energy during this operation.

Heat is produced as a result of the energy wasted in a transformer. Compared to the quantity of energy exchanged, minimal energy is wasted inside a transformer. But when the kVA rating increases, it grows significantly. Heat dissipation is a challenging problem for transformers with high kVA ratings. If the heat dissipation is improper, the transformer temperature will increase and might harm the insulation. In order to prevent the thermal deterioration of insulation, temperature must be kept within an allowed range.

Different Electrical Transformer Cooling Methods

The size, type and acceptable conditions at the location where the transformer is located all affect the cooling method employed. There are two types of transformers: dry and oil-immersed. The transformer uses two different types of coolants;

- Air

- Oil (such as transformer oil or mineral oil)

Transformers that utilise oil as a coolant are referred to as oil-immersed transformers, whereas those that use air as a coolant are known as dry transformers.

The methods to use for a dry transformer are:

1). Air Natural (A.N) Cooling

2). Air Blast (A.B) Cooling

The methods that are applied to oil-immersed transformers are:

1). Oil Natural Cooling

2). Oil Natural Air Forced Cooling

3). Oil Natural Water Forced Cooling

4). Oil Forced Air Natural Cooling

5). Oil Forced Air Forced Cooling

6). Oil Forced Water Forced Cooling

Air Cooling

1). Air Natural (A.N) Cooling

For rating transformers with lower capacities (5 to 10 kVA), the exterior surface is adequate for heat dissipation. This kind of transformer makes use of enclosures to circulate air and dissipate heat from the case’s natural radiation. Instrument transformers are typically dry type and employ this technique for cooling, with the exception of higher voltages.

2). Air Blast (A.B )Cooling

Using this method, dry transformers are cooled. This technique involves using external fans (or) blowers to continuously push air across a transformer’s winding and core. This form of cooling is employed in locations where oil is regarded as a fire threat and up to ratings of less than 25 kVA.

Oil Cooling

1). Oil Natural Air Natural (ONAN) Cooling

The transformer’s winding and core are submerged in oil during this cooling process. The enclosure is an iron tank filled with oil. Conduction is the mechanism by which the heat generated by the core & winding is transmitted to the oil. As the oil comes into contact with hot components, its temperature rises. And cold oil replaces hot oil in that position. The heated oil radiates heat onto the tank surface, dissipating it into the environment.

The power transformer features a cooling radiator method with natural cooling and a 10 MVA maximum capacity. Due to the benefits listed below, this type of cooling is the one most frequently employed for oil-immersed transformers:

- Absence of dust

- Easily dissipates heat from the inside.

- No impact is had by moisture.

The volume expansion coefficient of the oil is large. So, natural convection effectively dissipates a lot of heat.

The transformer tank flat surface is insufficient for effective heat dissipation for a transformer with a high rating. Fins are utilised in this condition to expand the area where heat may dissipate. Radiators & tubes are frequently installed on the tank walls to further boost its ability to dissipate heat.

2). Oil Natural Air Forced (ONAF) Cooling

Transformers with medium to high capacities that are submerged in oil are cooled using this method. By pushing air towards the cooling surface, this method enhances cooling. With the support of fans, air is compelled to the outside surfaces (such as radiator, tank, tubes, etc.).

3). Oil Natural Water Forced (ANWF) Cooling

The winding & core are submerged in oil in this method. Additionally, copper cooling coils are flooded with water to promote heat dissipation. The coils are positioned inside oil surface and above the core. Heat is delivered to the water, which is then cooled in a cooling tower or spray pond. Where there is a natural water head, this approach works well.

4). Oil Forced Air Natural (OFAN) Cooling

Rarely is this approach applied. This method involves pumping the oil around. In a heat exchanger, heated oil is also cooled naturally by air flow. When the coolers on the transformer need to be removed, this method is helpful.

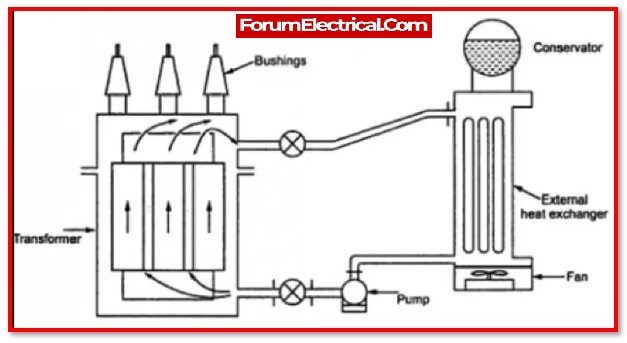

5). Oil Forced Air Forced (OFAF) Cooling

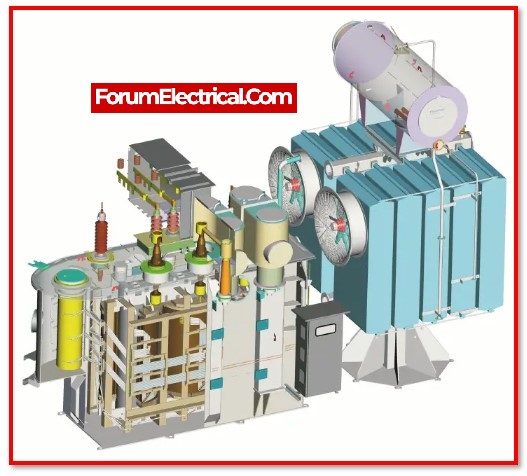

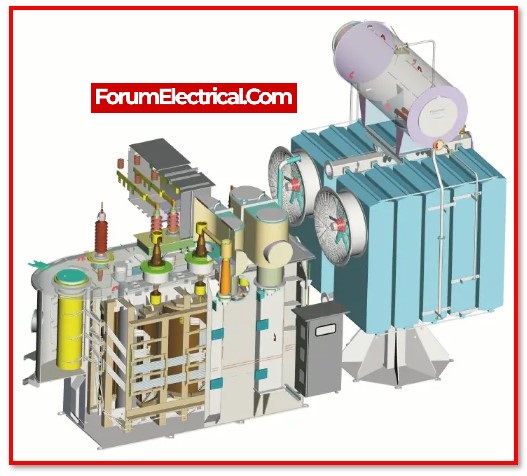

With this cooling method, a pump is used to circulate oil inside the transformer. An external heat exchanger cools the hot oil. With the aid of a fan, the air is blasted for additional cooling. Temperature sensors are often employed in the above way.

The transformer losses that occur under light load conditions are minimal, and minimal heat is produced. If the temperature rises, the pump and fan may be turned on. Otherwise, the fan (or) pump may be turned off. This method, which is utilised for power transformers with a rating of 30 MVA or more, increases the efficiency of the entire system.

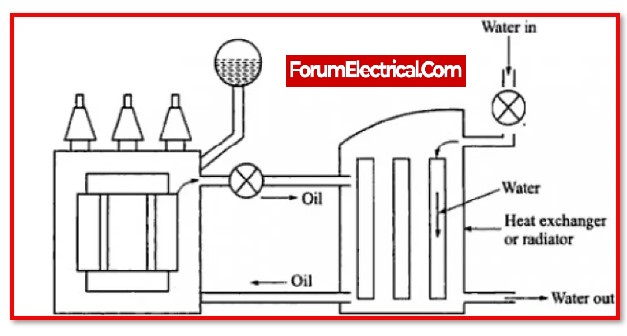

6). Oil Forced Water Forced (OFWF) Cooling

With this method, a pump is used to remove the heated oil from the main tank & move it to the heat exchanger. In a heat exchanger, the water flowing through copper tubes cools the oil. To prevent any oil-to-water leaks, the oil pressure remains higher than the water pressure. The hydroelectric power plant is appropriate for this type of cooling system.