- What is an Air Circuit Breaker?

- Components of ACB

- Construction of Air Circuit Breaker

- Air Circuit Breaker Working Principle

- Air Circuit Breaker Working

- Types of Air Break Circuit Breakers

- Maintenance of Air Circuit Breaker

- What is the operating principle of ACB?

- Advantages of Air Circuit Breaker

- Disadvantages of Air Circuit Breaker

- Application of Air Circuit Breakers

- Which air is used in ACB?

- What are the 3 coils of ACB?

- Relevant Codes & Standards of ACB

A circuit breaker is a type of electric equipment used to manually or remotely interrupt any circuit under normal conditions. A circuit breaker, often known as a CB, is designed to break a circuit in the case of a short circuit, overcurrent, or other fault conditions.

A circuit breaker is typically used to switch or protect a system.

- Relays,

- Switches, and

- Fuses

are examples of devices that are linked with circuit breakers.

Circuit breakers are primarily used in power systems and industry to protect and control various circuit components such as

- Transformers,

- Motors,

- Switch gears,

- Alternators, &

- Generators.

In industries, various types of circuit breakers are employed, one of which is the air circuit breaker.

This post provides an overview of air circuit breakers (ACB).

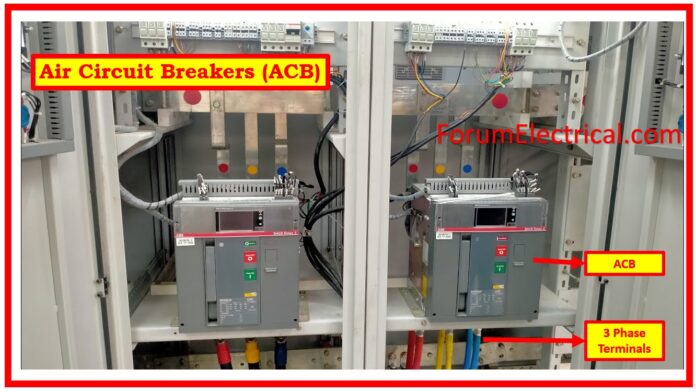

What is an Air Circuit Breaker?

An electrical component known as an air circuit breaker (ACB) provides

- Overcurrent protection &

- Short-circuit protection

for electric circuits ranging from 800 amps to 10,000 amps.

These are typically utilized in low voltage applications below 450 volts. These systems can be found in distribution panels (with voltages below 450V). In this post, we will look at how an air circuit breaker works.

An air circuit breaker is a circuit operation breaker that uses air as an arc extinguishing medium at a specific atmospheric pressure.

There are various kinds of air circuit breakers & switching gears available on the market nowadays that are long-lasting, high-performing, and simple to install and maintain. The air circuit breakers have totally replaced the oil circuit breakers.

An air circuit breaker:

- Operates at atmospheric pressure in air (using air-blast as an arc quenching medium).

- It has been entirely replaced with an oil circuit breaker.

- There is no risk of oil fire, as in an oil circuit breaker.

- With a rating of current up to 10,000 A.

- Trip thresholds & delays are customizable.

- Electronic and microprocessor-controlled.

- It is utilized in large industrial plants for primary power distribution.

Components of ACB

Main & Auxiliary Contacts

The ACB has two pairs of contacts: the main contacts, constructed of copper, carry the current, whereas the auxiliary (or) arcing contacts, made of copper alloy, protect the main contacts from arcing.

Arc Chute

The arc chute is a chamber that surrounds the contacts. It is composed of refractory material and is intended to cool & extinguish the arc. The inner walls of the arc chute are designed to drive the arc into close contact, allowing for effective quenching.

Trip Units

The trip unit detects problems and initiates contact opening. It consists of safety relays and sensors that measure the circuit’s current and voltage levels.

Closing and Opening Mechanisms

The ACB’s operation is controlled by its shutting and opening mechanisms. It incorporates springs, solenoids, & mechanical connections to provide smooth and dependable switching.

Construction of Air Circuit Breaker

An air circuit breaker could be constructed utilizing a variety of internal and exterior components.

ACB’s internal components primarily include a steel sheet-supported structure, a current transformer used to protect the trip unit, a pole group insulating box, horizontal terminals, an arcing chamber, protective trip unit, terminal box, closing springs, control for opening & closing the CB, movable plates for both arcing & main contacts, & stationary plates for both arcing & main contacts.

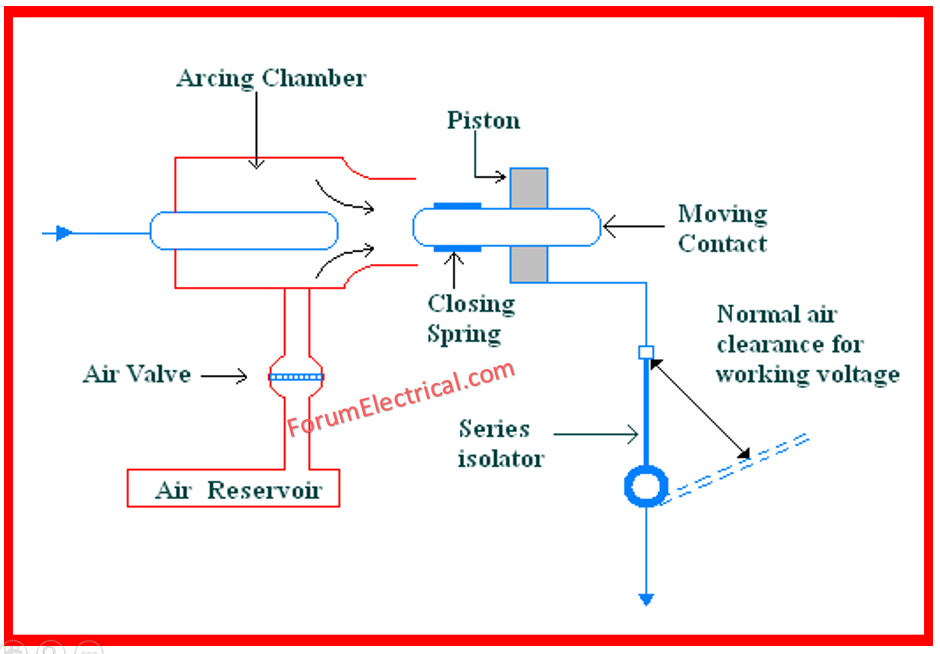

Air Circuit Breaker Working Principle

The working principle of an air circuit breaker differs from that of other types of circuit breakers. We know that the primary function of a CB is to prevent the restoration of arcing whenever the distance between contacts resists the system’s recovery voltage.

The air circuit breaker functions similarly, but in a different way. While interrupting an arc, an arc voltage is generated in place of the voltage supply. This voltage may be defined as the minimum voltage required to maintain the arc. A circuit breaker has three options for increasing the voltage supply.

The arc voltage might be increased by cooling the arc plasma.

When the temperature of the arc plasma & particle velocity are lowered, an extra voltage gradient is required to maintain the arc. The arc voltage may be enhanced by breaking the arc into multiple series.

When the arc path is expanded, the arc voltage can likewise increase. As arc path length increases, the path of resistance increases, as does the arc voltage used over the arc route, allowing arc voltage to be raised.

The operational voltage is up to 1KV. It has two sets of contacts, with the principal pair using current and the other built of copper. Another pair of contacts can be formed using carbon. The first primary contact unlocks when the circuit breaker is opened.

While opening the primary contact, the arc contact remains attached. When arc contacts are split, arcing begins. The circuit breaker is out of date for the average voltage.

Air Circuit Breaker Working

- Air circuit breakers work with contacts exposed to free air and use a different method of arc quenching than oil circuit breakers.

- Air circuit breakers, which are typically used for low-voltage interruptions, are gradually replacing high-voltage oil breakers.

- They have two pairs of connections: primary contacts of copper& arcing contacts of carbon.

- During the opening process, the main contacts separate initially, but the arcing contacts remain in touch, giving a low-resistive channel for current.

- Arcing happens only when the arcing contacts gradually separate.

- Thermal and electromagnetic phenomena cause arcs to be directed upward, where they enter an arc chute containing splatters to cool & prolong the arc before extinguishing it at zero current.

- The arc chute, made of insulating & fireproof material, is split into parts by barriers, each of which has a conducting element to ensure electrical continuity.

- Electromagnetic forces inside each chute segment cause the arc to form a helix, increasing its length & resistance while decreasing the current.

- At current zero, ionized air produces a shunt resistance over the open contacts & self-capacitance, dampening oscillations and preventing restriking.

Types of Air Break Circuit Breakers

Air circuit breakers are classified into four types and are commonly used to maintain the indoor medium voltage & switch gears of a home.

- Plain Break Type ACB

- Magnetic Blowout Type ACB

- Air Chute Air Break Circuit Breaker

- Air Blast Circuit Breaker

Plain Break type Air Break Circuit Breaker

Plain brake air circuit breakers are the most basic type of air breakers. The major points of contact are shaped like two horns. The arc of the circuit breakers runs from one end to the other. This type of circuit breaker is often referred to as cross blast ACB. This can be accomplished by creating an arc chute (chamber) that surrounds the contact.

The chamber (or) arc chute aids in cooling and the assembly of refractory material. The arc chute has walls inside and is divided into small sections with iron separating plates. These plates are arc splitters, and each compartment functions as a mini-arc chute.

The first arc will be divided into a series of arcs, resulting in higher arc voltages than the system voltage. These are used for low-voltage applications.

Magnetic Blowout Air Break Circuit Breaker

Magnetic blowout air circuit breakers are utilized at voltages of up to 11KV. The magnetic field generated by the current in the blowout coils may assist to extend the arc.

This type of circuit breaker exerts magnetic control over the arc moment, causing arc extinction in the devices. As a result, its extinction can be regulated using a magnetic field generated by current flowing through blown coils. The blow-out coils may be connected in series when the circuit is disturbed.

As the name implies, these coils are known as ‘blow out the coil’. The magnetic field does not handle the arc created in the circuit breaker; instead, it moves the arc into arc chutes where it is cooled and extended appropriately. These kinds of CBs are used up to 11kV.

Air Chute Air Break Circuit Breaker

In the air chute air break circuit breaker, the main contacts are typically constructed of copper and conduct current when closed. Air chute air break circuit breakers have a low contact resistance and are silver-plated. The arcing contacts are solid, heat-resistant, and constructed of copper alloy.

This circuit breaker has two types of contacts: main and arcing or auxiliary. Main connections can be designed with copper or silver plates, which have lower resistance and conduct electricity within a confined location. Other varieties, such as arcing and auxiliary, are made of heat-resistant copper alloys.

These are utilized to protect the primary contacts from arcing and may be easily replaced when needed. When using this circuit breaker, both contacts are opened after and before closing the main connections.

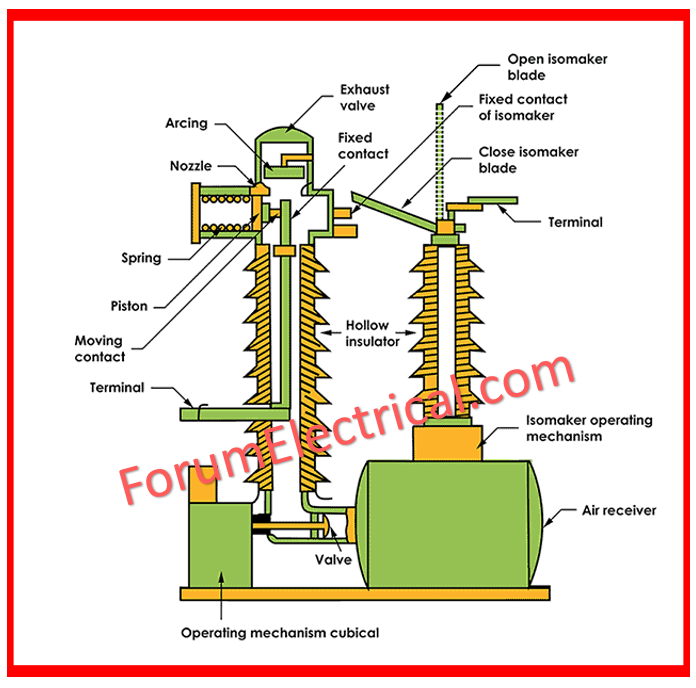

Air Blast Circuit Breaker

These circuit breakers are utilized for system voltages ranging from 245 KV to 420 KV, and even higher, especially when rapid breaker functioning is required.

Advantages of Air Blast Circuit Breaker:

- Fire hazards cannot be caused.

- Throughout its operation, this circuit breaker has a fast breaking speed.

- Arc quenching is faster during the operation of this breaker.

- The arc duration is consistent across all values of current disturbances.

- When the arc duration is reduced, less heat is transferred from the arc to the contacts, resulting in a longer service life.

- The system stability is well maintained as it is determined by the circuit breaker’s working speed.

- It requires less maintenance than oil-type circuit breakers.

- There are three types of air blast circuit breakers:

- Axial blasts,

- Axial blasts with sliding moving contacts, and

- Cross blasts.

Maintenance of Air Circuit Breaker

ACBs function as circuit protection devices for a wide range of applications that require low voltage up to 600V AC, such as UPS, generators, micro power stations, MCCB distribution boards, and so on, with sizes ranging from 400A to 6300A or more.

In this circuit breaker, roughly 20% of power distribution system failures are caused by a lack of maintenance, difficult grease, dust, corrosion, and frozen parts. As a result, circuit breaker maintenance is the best way to assure constant operation while also extending its lifespan.

Air circuit breaker maintenance is essential. It should be switched off first, then disconnected from both sides by opening the appropriate electrical isolator.

Every year, the circuit breaker should be tested in this no-isolation situation for restricted & distant areas. The circuit breaker must be manipulated electrically from restricted to isolated, then mechanically from restricted. This operation will improve the consistency of the breaker by detaching any outer layer formed between sliding edges.

What is the operating principle of ACB?

A magnetic field is used by a magnetic blowout type ACB to help remove the arc. The arc is not extinguished by the magnetic field. The blowout coils produce a magnetic field when the arc forms. The pressured air in the chutes causes the arc to expand and finally disappear, while the magnetic field assists in moving it along.

Advantages of Air Circuit Breaker

- Air blast circuit breaker is an ideal choice to employ where frequent operation is necessary because of the decreased arc energy.

- The use of an ACB eliminates the possibility of fire.

- Because of the rapid increase in dielectric strength, the ACB is compact in size.

- During the functioning of the air blast, the circuit breaker’s speed increases significantly.

- Arc quenching is far faster.

- The arc lasts the same amount of time regardless of current.

- The stability of operation may be maintained & is determined by the speed with which circuit breakers are operated.

- It requires minimal maintenance.

Disadvantages of Air Circuit Breaker

- The air-supply plant requires extra repair.

- It has a high-capacity air compressor.

- There is a potential of air pressure leaking at the air pipe connector.

- There is a potential of a rapid increase in re-striking voltage & current chopping.

- The air has relatively modest arc extinguishing properties.

Application of Air Circuit Breakers

- It is used to protect plants.

- It is widely used to protect electrical machines.

- It protects transformers, capacitors, and generators.

- ACB is also utilized in electricity sharing systems, while NGD is around 15kV.

- Also utilized in low-voltage and high-current applications.

Which air is used in ACB?

Electronic devices known as air circuit breakers (ACBs) are used to safeguard electrical circuits against overcurrent or short circuits. In air, the ACB functions at atmospheric pressure. ACB is utilized in the electrical system’s protection and switching mechanism.

What are the 3 coils of ACB?

- Under Voltage Coil (UV Coil),

- Shunt Trip Coil, and

- Closing Coil

are three of the parts of an ACB that cooperate to provide dependable and safe functioning.

Relevant Codes & Standards of ACB

- IEC 62271-100: Alternating current circuit-breakers; High-voltage switchgear and control gear.

- IEEE C37.04: The IEEE Standard Rating Structure for AC High-Voltage Circuit Breakers.