Generator

Electrical generators, which are also known as dynamos, are machines that convert mechanical energy into electrical energy.

Electrical generators are also known as dynamos.

Typically,

- Steam Turbines,

- Gas Turbines, (or)

- Wind Turbines

are the systems that are responsible for supplying this mechanical energy. The majority of the electricity that is required for electric power grids is supplied by electric generators, making them an extremely important component.

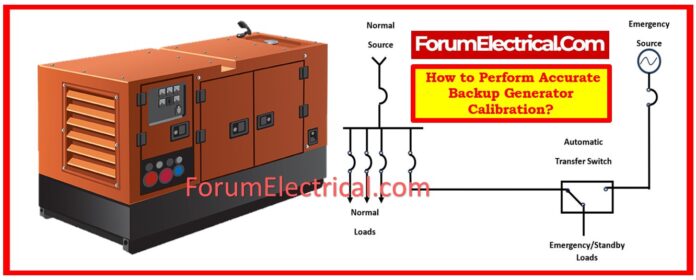

In case there is a disruption in the supply of electricity, a backup generator can be utilized as an alternative power source that is made to automatically activate and supply electrical power.

In case of an emergency, it is an instrument that is absolutely necessary for guaranteeing that key systems and equipment continue to function normally.

Calculation of the Backup Generator

Step 1: Initially, you will need to make a list of all of the loads that require power in order to proceed.

The total wattage will give you how much power your equipment needs, so you can calculate the base generator input.

Wattage information is on the equipment’s silver nameplate or manufacturer’s handbook.

NOTE: Certain electrical equipment has various starting & running wattages. Starting equipment with an electric motor uses more energy than keeping it running. It’s useless to have a generator that meets your running needs but can’t start the load.

Step 2: In the second step, you will find out the starting wattage (the amount of energy required to turn it on) and the running wattage (the amount of energy required to operate it) for each individual piece of machinery.

Step 3: Complete the third step by adding up all of the connected loads in kilowatts.

Step 4: The fourth step is to use the formula to convert the connected load from kilowatts to kilo amperes (kVA). Power Factor equals Kilowatt-Volts, or kVA. (kVA= kilowatt / Power Factor).

Generators are rated in kilovolt-amperes (kVA). kVA is a measure of perceived power, which indicates the total amount of power in utilization within a system. For a system that is completely efficient, kW must equals kVA.

However, electrical systems are never completely efficient, consequently not all of the system’s apparent power will be employed to produce useful work output.

Step 5: Check that the loads continue to be less than seventy percent (70%) of the generator’s capacity for industrial-strength units & between eighty and ninety percent (80-90%) for portable home models throughout the fifth step.

Step 6: The sixth step is to look at the product’s instructions in order to determine the suitable size of the generator.

Once you’ve evaluated the load size & factored in your power needs, you’ll have a fair sense of how much electrical input a generator requires. The next step is to ensure that your power requirements are realistic given the conditions & location of your site.

Solved Example

For the purpose of determining the suitable size for a diesel standby generator that operates around the clock, every day of the year, and supports loads that total 360 kilowatts, it is necessary to calculate the size of the generator that is required to maintain these loads in the event that there is a power outage.

To guarantee that the generator is capable of handling a load voltage of 415V while maintaining a power factor (PF) of 0.8, the calculation should be performed.

Step 1: List of the load.

Step 2: A total connected load of 360 kW is being utilized.

Step 3: Kilowatt-hour (KVA): 450 KVA

Step 4: Formula for Generator Capacity

Generator Capacity Formula

Generator Capacity (Large-Industrial) = KVA/0.7 = 450/0.7 =643kVA

G.C (large size-industrial) – kVA/0.7

G.C (Residential) – KVA/0.9 (or) KVA/0.8

Step 5: Choose the appropriate DG set size that is closest to the market rating of 660 kVA.