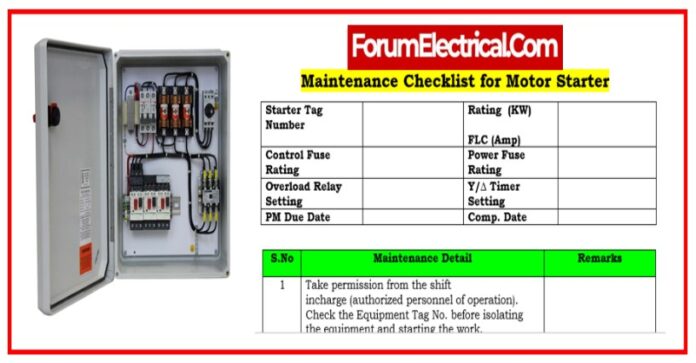

A motor starter is an important electrical equipment that is used to start and stop motors. Preventive maintenance is an essential necessity for maintaining the motor starter in beneficial condition. Many types of maintenance activities are performed on a monthly, quarterly, half-yearly, and yearly basis.

All of these operations are carried out in accordance with the maintenance checklist, which is a defined step-by-step maintenance process.

Motor Starter Safety Guidelines

During the Planned preventative maintenance (PPM) activity, we must pay attention to the safety guidelines in order to prevent any mishaping from occurrence. There are various safety-related points that are discussed below:

- Separate the source of the electrical energy from the electrical service panel.

- The electrical panel should be secured using lock out and tag out.

- Make use of tools that are insulated.

- Utilize personal protective equipment such as safety shoes, helmets, and other equivalent equipment.

- Dispose of the tools and tackles once the work has been finished.

- Once the work is finished, remove the safety lock and any signboards or tags.

Checkpoints for Motor Starter Maintenance

- Ensure that there is no power supply before starting any maintenance work.

- Examine the connections for the thimbles, neutral, earth, and input/output.

- Examine the selector switch, push button, and indicator.

- Verify the pushing function & terminal heating of each contactor.

- Verify that the protective relay is set for the motor capacity.

- Use an air blower to clean, then properly dress.

- Verify the panel body’s earth connection.

- Check for any strange sounds when the load is applied.

Parameters Status

- After doing maintenance, we should verify parameters to ensure that the equipment is in good working condition.

- Input Voltage

- Check the load in comparison to the capacity.

- Check the parameters with respect to the default limit.

- Examine any odd sounds.

Why is Maintenance for Starter Panels important?

The contacts on the panel become electrified each time the motor is turned on because electricity passes through them (high current passes through during starting). There is a little spark produced in the contacts when the switch is turned ON or OFF. This spark will harm poor connections, causing carbon deposits on contact surface and pitting or scoring marks in the contacts.