- What is an OCP-operational control procedure?

- Electrical Operational Control Procedure

- Purpose and Scope

- Responsibility

- Overview of the Process

- Pre-Operation (Pre-Op) Inspections

- Initial (Start-Up) Procedures

- Typical Function

- Abnormal Conditions

- Closing Procedures

- Maintenance Methodologies

- Emergency Reaction

- Record-keeping and Documentation

- Training Knowledge

- Analysis and Correction

- Attachment

What is an OCP-operational control procedure?

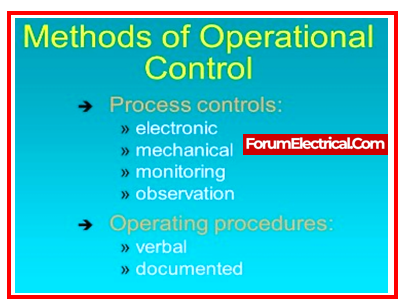

It is the process to ensure that specific operations are executed successfully and efficiently via operational or task control. The management of individual tasks or operations is the focus of operational control. It focuses on the scheduling & control of specific works within the manufacturing facility rather than the overall efficiency of the firm.

Electrical Operational Control Procedure

Electrical systems must operate safely and effectively, and this is ensured by sets of rules and procedures known as electrical operational control procedures. Aspects of electrical operations such as

- Startup,

- Shutdown,

- Maintenance, and

- Emergency response

are typically addressed by these processes.

They essentially provide a methodical strategy to electrical system management that helps prevent accidents, ensure adherence to safety rules, and preserve equipment dependability. Instructions for testing, isolating, labeling, and other safety precautions to shield people and equipment from electrical risks may be included in these protocols.

The industry, type of facility, and complexity of the electrical systems involved can all affect the specifics of electrical OCP (operational control procedures). They are essential in settings like industrial complexes, power plants, and sizable commercial buildings where power supply is a vital component of operations.

Fundamental components which integrate into an electrical operational control procedure:

Purpose and Scope

Establish in simple terms the procedure’s primary objective, which is often to ensure the effective and safe operation of the electrical systems.

Describe the range of electrical systems and equipment that the procedure covers in order to define its scope.

Responsibility

Determine and specify each person’s position and responsibility in relation to the electrical activities. Operators, technicians, managers, and safety staff may fall under this category.

Indicate the credentials and education needed for employees doing electrical operations.

Overview of the Process

Give a high-level summary of all the stages and important processes involved in the electrical operational control process.

Pre-Operation (Pre-Op) Inspections

Summarize the checks and tests that must be carried out prior to starting any electrical operations. This could involve eye examinations, equipment status checks, and safety measure verification.

Initial (Start-Up) Procedures

Provide the procedure that must be followed in order to safely turn on electrical systems. This covers the order of operations, the equipment that needs to be powered on, and any particular factors for various parts.

Typical Function

Describe the electrical systems’ typical conditions of operation. When operating normally, provide any operational parameters, requirements for monitoring, and continuing maintenance tasks.

Abnormal Conditions

Indicate the actions that should be taken in the case of abnormal circumstances, such as equipment failures, voltage fluctuations (or) other unanticipated factors.

Give assistance on troubleshooting and remedial measures.

Closing Procedures

Provide the secure methods for turning off electrical systems. This could involve certain procedures for isolating machinery, safety inspections, and de-energizing it.

Maintenance Methodologies

In order to assure the continued dependability of electrical equipment, include instructions for regular maintenance tasks, planned inspections, & any preventive measures.

Emergency Reaction

Describe the emergency protocols that must be adhered to in the event of fires, electrical accidents, or other severe conditions. Provide communication guidelines, emergency shutdown procedures, & evacuation strategies.

Record-keeping and Documentation

The importance that it is to keep complete documentation of all electrical operations, particularly test results, maintenance tasks, and any errors that occurred. Indicate the type of documentation is needed.

Training Knowledge

Emphasize the necessity of continuous training and competency evaluations for employees engaged in electrical operations. Make sure that everyone is aware of the protocols and knows their responsibilities.

Analysis and Correction

Provide an interface for the electrical operational control procedure’s routine evaluation and, if required, amendment to make sure it stays up-to-date and helpful.

Keep in consideration that the specifics of these steps will differ based on the industry, legal regulations, and the level of complicated the electrical systems in problem.