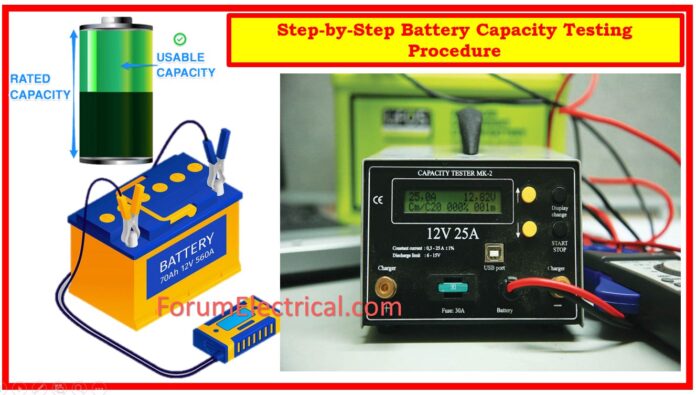

This post demonstrates the procedure to test the capacity of a battery. The test will determine and compare the battery’s real capacity to its rated capacity.

A load bank, voltmeters, and an amp meter will be utilized to discharge the battery at a specific current till a minimum voltage is achieved.

The findings will be recorded across time intervals to determine whether the battery matches the required amp-hour rating according to discharge current & duration.

There are unique discharge processes for each battery model to verify their capacity in accordance with manufacturer norms and specifications.

Scope

Test the capacity of batteries.

Test Purpose

The purpose of this test is to compare the battery’s real capacity to its rated capacity.

Reference

Refer to applicable manufacturing standards, contract specifications, and construction drawings.

Battery Preparation

- To prepare the battery, measure and record the open circuit voltage of each cell or unit to ensure a minimum permissible voltage before interconnecting.

- Connect individual cells/units using the application-specific cables or busbars that are rated for the battery’s performance.

- To ensure full charge, equalize the battery for 24 hrs at the appropriate voltage.

- After equalization, float charge the battery at the appropriate voltage for 3-7 days before acceptance testing.

- Before starting the acceptance capacity test, measure & record individual cell/unit float voltages.

Equipment Requirements

- Load bank capability of delivering the required discharge current.

- Use digital voltmeters to check entire battery discharge voltage.

- Use an amp meter to check battery discharge current.

- Use a digital voltmeter to check individual cell/unit voltages undergoing discharge.

- Use a stopwatch to check discharge time.

Test Conditions

Brand:

Manufacturer:

Model:

Rated Capacity:

Voltage per cell:

Design Life:

Quantity per Bank:

Discharge Current:

End Voltage:

Time:

Temperature: ____°C.

Test Procedure

Step-1: Ensure instrumentation is operational & properly connected to the battery for continuous monitoring of discharge voltage and current.

Step-2: Measure the float voltage of the each cell/unit to ensure appropriate flotation.

Step-3: Disconnect the charging current from battery.

Step-4: Connect the load bank to the battery when it is powered off.

Step-5: Start the timer and activate the Load Bank, adjusting and maintaining the optimum discharge rate.

Step-6: Record battery discharge voltage, current, & time at the start & the end of the test, as well as at regular intervals throughout the test.

Step-7: End the capacity test when the battery reaches the predetermined end point voltage (1.8V), a cell (or) unit reverses, or a safety issue is identified.

Calculation Requirements

- The ampere-hour rating is calculated by multiplying the number of amperes of current that the battery can supply by the number of hours it takes to reach a specific end point voltage.

- For an accurate current determined during the test, the time of the test should match the calculation.

Test Record

| 30 seconds | 1h | 2h | 3h | 4h | 4.5h | 5h | ||

| Battery Voltage (V) | 108 |

| Tested by | Verified by | Supervised by | ||

Signature | ||||

| Name | ||||

| Date | ||||

Battery Capacity Calculation Methods

With the test above, you can calculate your demonstrated capacity. It can be calculated in two ways:

- Rate Adjusted Method

- Time Adjusted Method

Rate Adjusted Method

When testing for less than an hour, always utilize the rate-adjusted approach. For durations of one hour or more, either the rate adjusted or time adjusted technique can be applied. IEEE 450 and IEEE 1188 provide a full explanation of the rate adjusted approach, with examples.

Time Adjusted Method

The time-adjusted technique is recommended since it is easier to calculate while remaining accurate.

See the time-adjusted approach that follows:

Battery Temperature as 25°C

To compute % capacity using the time adjusted technique, divide actual discharge time by the rated time, then multiply by 100. This assuming the battery is at 25°C.

Formula: % Capacity = Ta/Ts x 100

Where

Ta – Actual Test Time

Ts – Rated Test Time

Battery Temperature is not as 25°C

When the battery temperature is not as 25°C, use a barely modified formula utilizing a temperature correction factor (K) from the corresponding IEEE standard.

Formula: % Capacity at 25°C = [Ta/ (Ts x Kt)] x 100

Where

Ta – Actual Test Time

Ts – Rated Test Time

Kt – temperature correction factor based on the applicable IEEE standard.