- What is Electrical Busbar?

- Selection or Purpose of Electrical Busbars

- Uses of Busbars

- What effect do busbars have on energy efficiency?

- Why is busbar utilised rather than wire in applications?

- Type of Busbars

- Single Busbar System

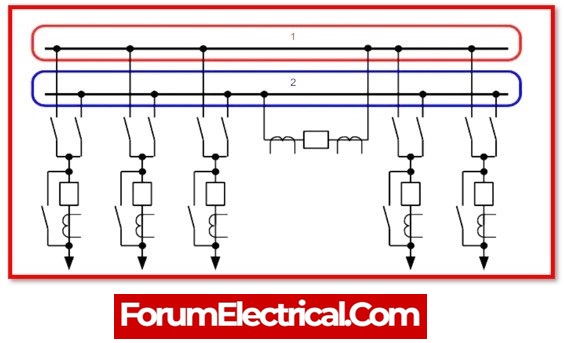

- Double Busbar System

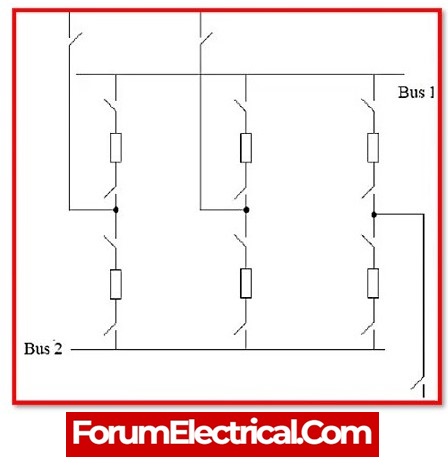

- Sectionalized Double Busbar Arrangement

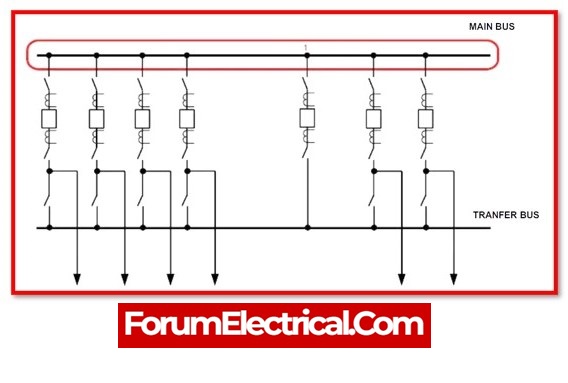

- Main and Transfer Bus Arrangement

- Ring Busbar System

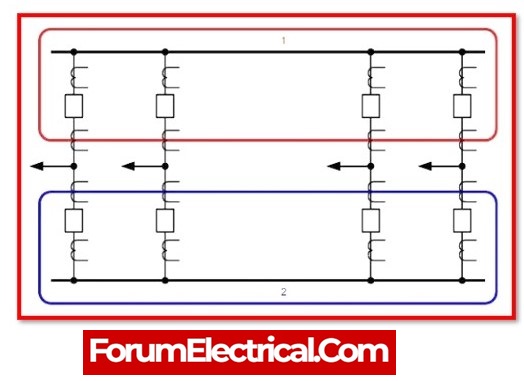

- One and Half Busbar Arrangement

- Mesh Arrangement

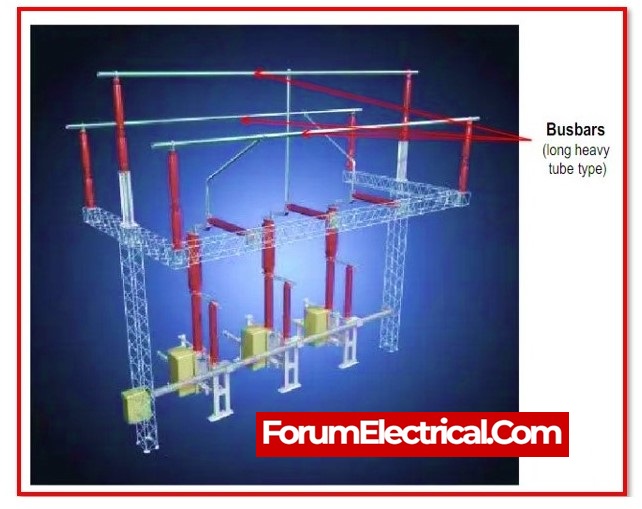

What is Electrical Busbar?

Electrical busbar is basically a type of conductor that collects power from the incoming feeder and transfers to the output feeder. In other words, it is a type of electrical power junction where currents that come and go together connect.

As a result, the electric bus bar absorbs electricity in one location. Electrical busbars employ

- Isolators and

- Circuit breakers

to protect substation equipment during fault conditions.

When a problem occurs, the circuit breaker trips, and the malfunctioning portion of the busbar is easily removed from the circuit. Busbars come in a variety of shapes, including

- Rectangular,

- Cross-sectional,

- Round, and

- Many others.

Rectangular busbar strips are commonly used in power systems.

Electrical Busbar is made up of a number of lines that all operate at the same voltage and frequency. Busbars are often made of

- Copper or

- Aluminium conducting material.

a) What is Copper Busbar?

Copper has minimal electrical and thermal resistance and is durable. Copper’s impact (higher) resistance makes it an essential component in electrical busbars. Switchgear, panel boards, and busway enclosures distribute high current efficiently. It can be employed for almost any requirements application.

b) What is Aluminium Busbar?

Aluminium busbars are lighter than copper, making mass production inexpensive. It’s ideal for firms in concern budget, weight, and installation. Aluminium’s 70% lower density than copper makes it ideal for situations where busbar sizing is not a requirement.

The most common busbar sizes are

- 40 × 4 mm (160 mm2),

- 40 × 5 mm (200 mm2),

- 50 × 6 mm (300 mm2),

- 60 × 8 mm (480 mm2),

- 80 × 8 (640 mm2) and

- 100 × 10 mm (1000 mm2)

They are often used in the form of pipe or tubes with thin wall thickness.

FOR ELECTRICAL SYMBOLS CLICK HERE

Selection or Purpose of Electrical Busbars

The electrical power system employs a variety of busbar designs. The selection of a busbar is influenced by a variety of elements such as

- Dependability,

- Flexibility,

- Cost, and so on.

It’s been selected because of the characteristics listed below:

- Electrical Busbars design is simplistic and requires minimal maintenance.

- The system’s maintenance has no effect on electrical busbars durability.

- Installing a bus bar is less expensive than other systems.

A single busbar system is employed in small substations when there is no constant need for the power. In the large substation, however, more than one busbar is employed when opposed to the smaller substation. As a result, the problem of power failure trip outages is avoided.

Uses of Busbars

Busbars are the go-to solution for many sectors when space is limited or alternate electrical distribution is required.

There are two varieties of busbars: laminated and flexible, and both serve a wide range of industries.

Laminated busbars are extensively used in the following applications (systems):

- Mobile communications systems

- Telephone (Phone) exchange systems

- Power and hybrid traction networks

- Area network stations

- Power converter switch systems

- Large network equipment systems

- Military (hardware & technology) equipment systems

- Power (Electricity) generation systems

- Electric power conversion modules

Flexible bus-bars are used in:

- Electric, hybrid, and fuel cell automobiles

- Electrical connections in switching (tap-changing) cabinets

- Generator power link

- Transformers & charging stations points.

Busbars have numerous advantages and are essential in electrical distribution systems. Busbars are also simply adjustable for renewable energy integration, with extreme versatility allowing easy adaptation for a variety of applications.

What effect do busbars have on energy efficiency?

Energy efficiency depending on the impact that busbars have on:

- Improves conductivity

- Power efficiency increases

- Flexibility without affecting strength or vibration absorption

- System costs reduced

- Improve dependability

- Increase capacitance

- Eliminate electrical wiring errors and

- Lower electrical inductance.

Why is busbar utilised rather than wire in applications?

Busbars are more resistant to damage than cables are, particularly in the event of a short circuit, because the design parts of busbars are rigid. Busbars ensure that the conductors are kept at a consistent distance from one another, which in turn lowers the amount of resistance that can be induced.

Type of Busbars

Busbars are classified into the following types based on their construction:

- Single busbar system.

- Double busbar system.

- Ring busbar system.

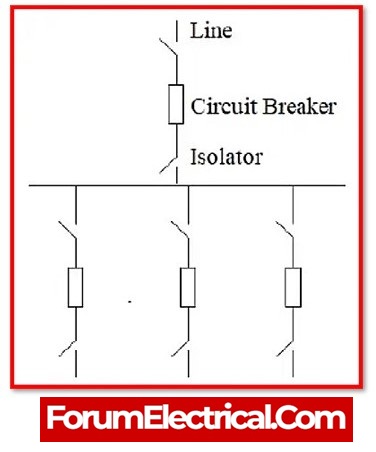

Single Busbar System

The single busbar system is incredibly basic and simple to establish. Along with the switch, the system contains only one bus bar. All substation equipment, such as the

- Transformer,

- Generator, and

- Feeder,

is only connected to this busbar.

Advantages of Single Busbar System

- Single busbar has a modest initial cost.

- Single busbar requires minimal maintenance

- Single busbar is simple to use in operation.

Disadvantages of Single Busbar System

- The disadvantage of this type of single busbar system is that when a breakdown occurs, the entire supply is interrupted.

- The configuration gives less flexibility and is hence employed in small substations where supply continuity is not essential.

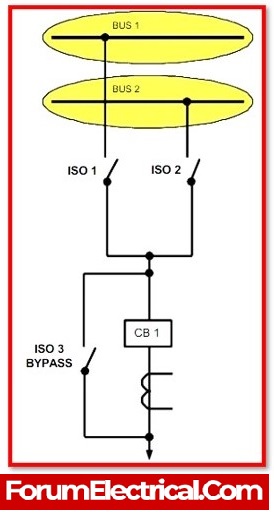

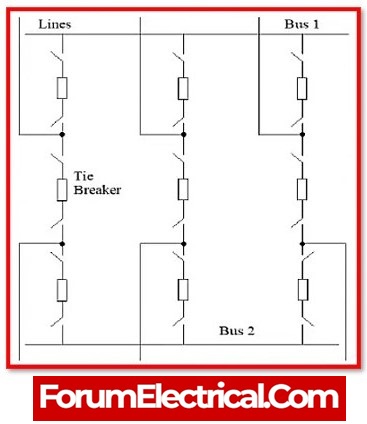

Double Busbar System

Low voltage and high voltage bus-bars are replicated in a double bus-bar arrangement. Any of the bus-bar parts from the two can be used as needed.

There is a bus-bar coupling switch configuration for shifting operation from one bus-bar to another.

By adding circuit breakers, a double bus-bar sectionalized system can be created as required. Double busbar system employs only two bus bar strips and two circuit breakers. It does not require a bus coupler or additional switches like

- Main Bus arrangement and

- Transfer Bus arrangement.

Sectionalized Double Busbar Arrangement

The sectionalized main bus busbar and the auxiliary bus bar are utilised in the sectionalized double bus bar arrangement. For maintenance, any portion of the busbar can be disconnected from the circuit and linked to any of the auxiliary bus bars. However, this form of configuration raises the system’s cost. The auxiliary bus bar does not need to be sectioned because it would raise the system’s cost.

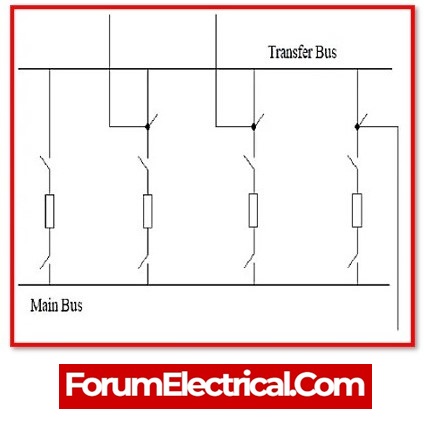

Main and Transfer Bus Arrangement

The main busbar and the transfer busbar are the types of busbars that are used in electrical panel power distribution system. Many switches that are used to connect the circuit breaker to the busbar are linked together by the bus coupler, which is part of the busbar system. In the event that there is a power overload, a bus coupler is used to transfer the load from one busbar crossing to another busbar crossing. The load can be transferred from one busbar to another busbar by carrying out the steps that are listed below:

- The closing of the bus coupler ensured that the probability of both bus strips would remain unchanged.

- The bus strip that is used to transfer the load is maintained at a close distance.

- Free up space in the main bus lane.

Advantages of Double Busbar System

- In the case of a double busbar system, one busbar can be “energised,” making it easier to carry out repairs on the other when necessary.

- Feeder circuit breakers can be tested on the spare bus bar while the main busbar remains untouchable.

- When a failure arises on the bus-bar, the circuit’s uninterrupted supply can be maintained by moving it to another busbar.

Disadvantages of Double Busbar System

- Two buses and two circuit breakers are utilised in this type of configuration, which raises the system’s cost.

- Their maintenance costs are expensive.

- Such bus-bars are rarely utilised in substations due to their increased cost.

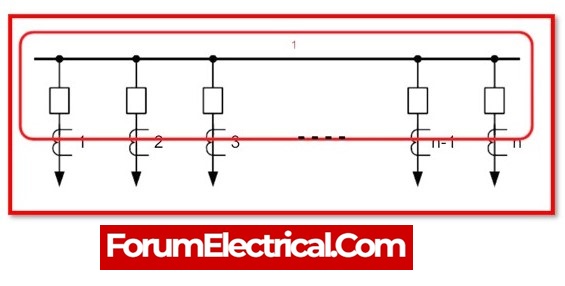

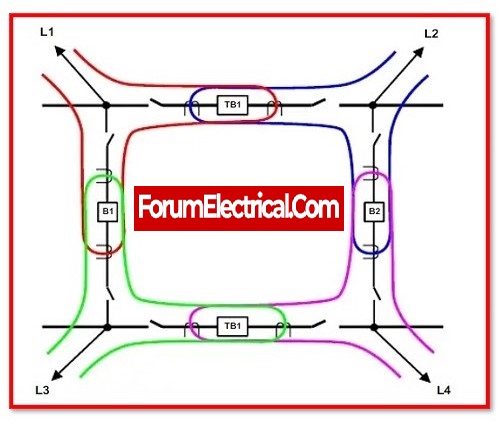

Ring Busbar System

The ring busbar system gives a double feed to each feeder circuit, opening one breaker for maintenance or otherwise having no effect on feeder supply. Two circuit breakers operate on a single line in this configuration.

This ring bus-bar system has the benefit of always having two parallel pathways to the circuit, thus failure of one path does not entirely interrupt service.

Advantages of Ring Busbar System

- This ring bus-bar system has an alternative path to the circuit, so the failure of one section does not fully interrupt service.

- Any circuit breaker can be serviced without causing a power outage.

Disadvantages of Ring Busbar System

- Difficulties occur during the installation of the new circuit.

- If any of the circuit breakers (CB) is opened, the system becomes overloaded.

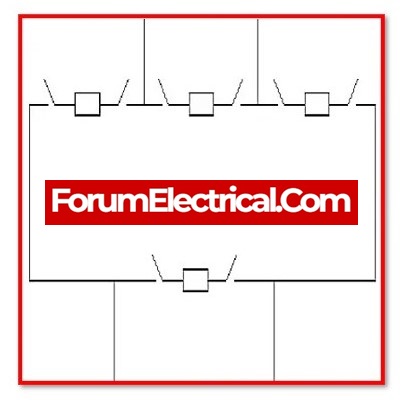

One and Half Busbar Arrangement

When using the One and a Half Breaker Arrangement, it will be needed three circuit breakers to power two separate circuits. Each individual circuit on the bus bar is protected by a one and a half circuit breaker. In large stations, where the amount of power handled by each circuit is significant, this particular configuration is the one that is most often used.

Mesh Arrangement

The circuit breaker in a mesh arrangement system is arranged in a net that is generated by the busbar. The node point of the mesh is where the connection to the circuit is made. The operation of this kind of bus system is managed by four circuit breakers.

When a fault occurs in any area of the mesh, two circuit breakers need to be activated, which ultimately results in the mesh being opened. In the absence of a switching mechanism, this configuration offers protection against bus-bar failures. In substations with a significant number of circuits, it is the preferred option.