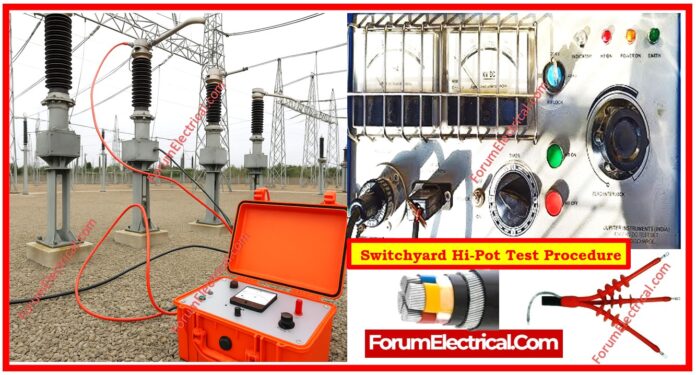

In a switchyard, a high-voltage dielectric endurance test called a “Hi Pot” is used to verify how well components and equipment are insulated.

It is carried out to guarantee that the insulation can withstand voltage spikes and avoid malfunctions, maintaining the electrical system’s dependability and safety.

Purpose of Switchyards Hi Pot Testing

Insulation Integrity

Verifies the insulation of devices such as

- Transformers,

- Circuit breakers, and

- Other switchyard parts

to make sure they can tolerate both anticipated and unforeseen voltage shocks.

Preventing Failures

Reduces the chance of damage and outages by identifying any insulation faults or weaknesses that can cause breakdowns during regular operation.

Safety Assurance

Ensures the safety of both people and equipment by confirming that the switchyard equipment complies with safety regulations and standards.

Key Considerations

Voltage Levels

Typically, the test voltage is double the operational voltage plus 1000V, or in accordance with applicable standards.

Test Duration

The test length is normally one minute, although it might vary depending on the equipment and requirements.

Safety

Safety measures are strictly maintained due to the high voltages (HV) involved.

Leakage Current

Monitoring leakage current is essential for identifying insulation faults.

Standards

Hi Pot testing follows a wide range of standards, including IEC 60950 for electrical products.

Purpose

This procedure establishes the way for carrying out the Hi Potential test of switchyard overhead conductor prior to energize by normal power.

Scope

This procedure is exclusively used for testing the overhead conductor 2 Line Bus Bar & 3 Bay Line at the switchyard.

Requirements

Prior to testing, the testing engineer should ensure that the construction work was completed, that all reports were signed by the owner, and that there were no punch list components left.

Every CT (Current Transformer) secondary connection must be shorted and connected to ground.

All CVT secondary must be disconnected from the protective system or another system.

All CB & DS (Distribution Suystem) should be closed in order for the equipment to be tested.

All HV cables to the power transformer should be unplugged and isolated.

All overhead cabling to the existing switchyard should be detached and hung in a safe location with adequate clearance.

The following components were tested for a 150kV switchyard system before being put into normal operation:

- Overhead cable Insulation Resistance

- Overhead cable Hi Potential test

Equipment Required

- Multi-Tester Megger

- Ammeter

- Cable Accessories

- Special tools

- HV Tester.

Safety Precaution

All personnel must wear Personal Protection Equipment (PPE), which includes a

- Uniform,

- Safety helmet,

- Safety shoes,

- Safety glasses, and

- Electrical safety glove.

Before starting the testing, ensure that all workers and supervisors attend a safety induction and toolbox meeting to ensure that the activity plan is clear.

All areas should have adequate lighting for working the night shift.

If working at heights greater than 2 meters, all personnel must wear a safety full-body harness and ensure that the scaffolding is correctly installed and inspected by a scaffolding inspector.

To protect humans from electrical shock during testing activities, cable power must be supplied via an ELCB. All testing equipment must have a calibration certificate.

All testing activities must be carried out by a competent individual in order to prevent equipment damage & ensure proper functioning.

Test Procedure

Insulation Resistance Testing Procedure

Standards: more than 500MΩ at 5000VDC.

- Prepare tools, and the cable are likely to be tested.

- Disconnect cable from the another circuit & isolate.

- Stand beside one person at end of the cable to ensure that nobody touches it.

- Connect the line wire from the tools to the overhead cable, the ground cable to the structure, and another overhead cable to the ground.

- Inject 5000 V DC electricity to overhead cable for 1 minute.

- Check that the value is more than the requirements.

- To prevent electrical shock, turn off the injection voltage & grounded overhead wire after testing.

- Repeat the previous steps for the other overhead cable.

Insulation resistance should be measured before and after the Hi potential test.

Hi Pot Testing Procedure

After finishing the insulation resistance test for the overhead cable, the hi pot test will be performed as shown below:

Standards: No flashover in the isolator.

- Stand with one person at end of the overhead cable to ensure that no one touches the cable.

- Connect the over-head cable core and test it with the cable from the hi-pot tools set.

- Connect the ground line from the tools to the grounding system.

- Connect the power supply for the hi pot tool set to the source.

- Turn “ON” the hi pot tools and gradually increase the voltage to the overhead cable until it reaches

Hipot Test Voltage = [(Vph x 2)+1kV] x 80%

Where

Vph – Phase-to-Ground Operating Voltage

1kV – Safety Margin

80% – Test Voltage Factor for Solid Insulation

for each phase.

This formula is commonly used during DC (or) AC High Voltage Testing (Hipot) at a switchyard to ensure the insulation integrity of equipment such as CTs, PTs, breakers, (or) busbars.

- Hold voltage for 1 minute for the AC voltage injection & fifteen minutes for DC voltage injection.

- Ensure that there is no breakdown voltage or flash over while injecting voltage into the overhead cable, & check leakage current for the reference test results.

- Reduce the voltage to zero & turn off the hipot tools set.

- To avoid electrical shock, short the overhead line to ground after injecting voltage.

- Repeat the previous steps for another cable.

- After completing the hi pot test of the overhead cable, an insulation resistance test must be performed to ensure that the isolator is still in good condition, using the insulation resistance (IR) test procedure outlined above.

Test Report

Advantages of Switchyard HiPot Testing

- Prevents malfunctions and guarantees that the switchyard operates safely.

- Detect potential issues early on, reducing the possibility of unexpected outages.

- Ensures that the switchyard equipment fulfills the necessary criteria and can function properly.