- What is a Single Phasing?

- What is Single Phase Preventer?

- Construction of the Single Phasing Preventer

- Working Principle of the Single Phasing Preventer

- What is the operation of a single phasing preventer?

- Types of the single phasing preventer

- What is the effect of the Single Phasing?

- Necessity for the single phasing preventer

- Applications of the single-phase preventer

What is a Single Phasing?

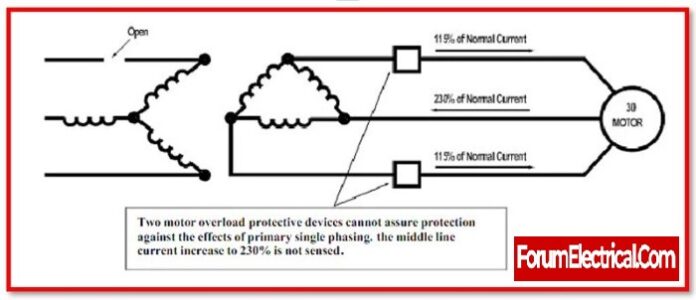

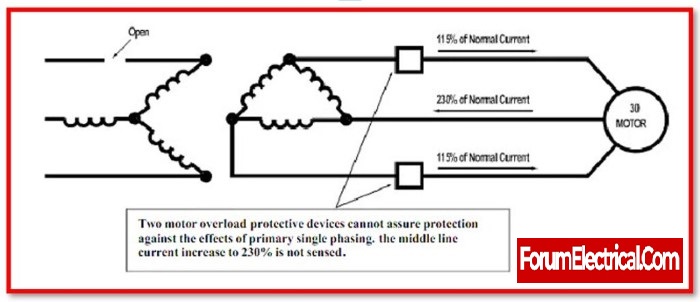

When a three-phase motor is running, single phasing occurs when one of the three phases is open circuited.

A three-phase motor is known to be more efficient than a single-phase motor. Each three-phase motor has either a delta or a star connector.

So, if one of the phases is open, they will continue to run, but at around 2.5 times the normal current during single phasing.

Single Phasing is defined as the absence of one of the three phases.

What is Single Phase Preventer?

A control device known as a single-phase preventer relay is one that can determine whether there has been an interruption in the phase supply and then energise the relay contacts that are associated with its auxiliary relay.

Meanwhile, this contact is given to the PLC, which uses the previously written code to switch off all of its outputs.

Construction of the Single Phasing Preventer

Main parts of single-phase preventer relay circuit:

- Control coil,

- Negative sequence filter,

- Contactors,

- NC-Normally Closed contact,

- NO-Normally Open contact,

- C.T.S,

- Thermal relay (Protective).

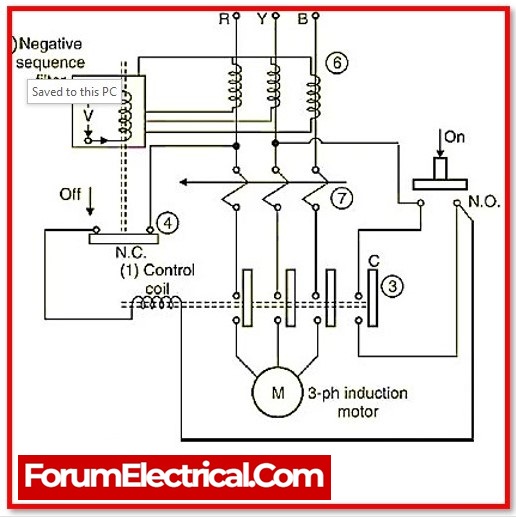

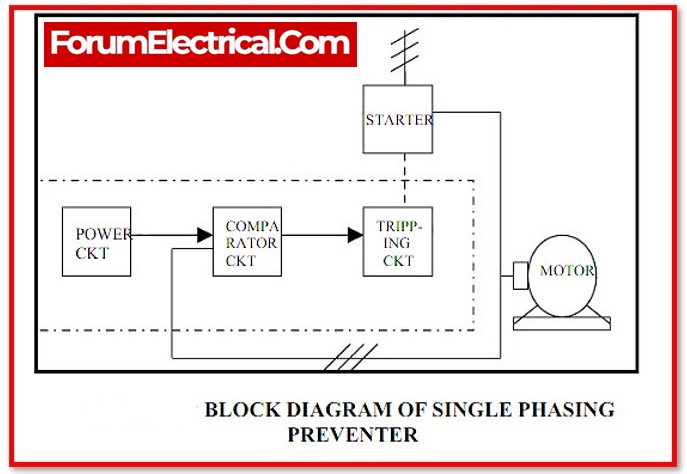

It is shown that the components are connected to the protection circuits as well as the motor. The preventive circuit is connected in the CT’s secondary, and the R.Y.B. lines operate as the CT’s primaries. The connection for the negative sequence filter is connected. A level detector is connected to the lifter’s output in order to collect data. This causes the tripping command to be transmitted to the starter, which in turn causes the NC contact to open and the contactors to open. This results in the motor being stopped because it is disconnected from the supply R.Y.B. This kind of preventer is typically used in motors with a capacity ranging from small to medium.

Working Principle of the Single Phasing Preventer

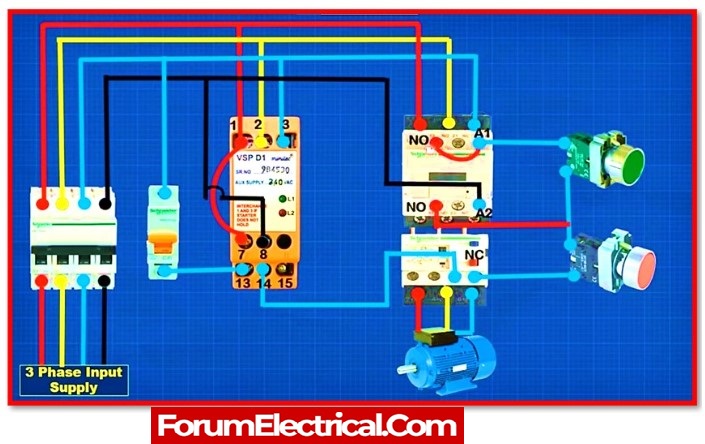

It typically has eight terminals. Three terminals are for 3-phase power, two for single-phase powering the relay device, and three for auxiliary contacts.

The device has numerous timer and other control parameter options for precisely monitoring the phase sequence. The internal circuit constantly monitors the imbalance phase sequence or abnormal phase operations and activates the relay output.

In the PLC, corresponding logic is developed to sense the digital input from this relay and switch off all outputs. This will disconnect the motor (or) other field equipment from the three-phase power source, preventing harm.

In practice, there are numerous causes of phase failure. Sometimes the contactors of a motor become open-circuited; or one of the fuses of any three-phase supply blows or melts; or the contactors become non-conducting owing to oxidation, etc.

In any case, an incorrect phase supply can break the windings of the motor, so this device must be used to prevent any unforeseen incidence.

What is the operation of a single phasing preventer?

A Single Phasing Preventer is similar to a switch in that it opens the circuit when there is a fault condition called single phasing and closes it when there is a normal condition. However, it automatically closes the circuit when there is no fault condition.

Types of the single phasing preventer

The operation of the single-phase preventer relay is based on the principle of monitoring the current and the voltage of the three-phase supply system. The relay is an example of the following:

- Mechanical type Single Phasing Preventer Relay

- Voltage sensing Single Phasing Preventer Relay and

- Current Sensing Single Phasing Preventer Relay

1). Mechanical type Single Phasing Preventer Relay

Bimetal relays have a single phasing preventer that opens the NVC circuit like an OLR (over load relay). Single phasing preventers are slow and unreliable. It’s no longer popular.

Coils connect two three-phase supply lines in the second mechanical phase failure relay.

These coils generate a magnetic field that turns a copper disc clockwise.

Two opposing torques create this clockwise torque. One torque rotates disc clockwise and one anti-clockwise. This disc has a toggle mechanism that opens the starter and disconnects the motor.

Thus, if a phase disconnects, its torque disappears, disconnecting the motor from the line.

Thus, mechanical single-phasing preventers protect motors.

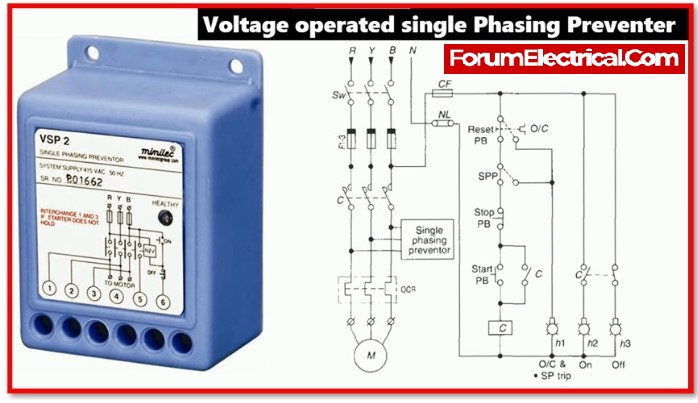

2). Voltage sensing Single Phasing Preventer Relay

The phase sequence of an alternating current (AC) three-phase supply refers to the order in which the three phase voltages reach their maximum value in a specific sequence.

The phenomenon known as positive phase sequence occurs when each phase voltage reaches its maximum positive value one after the other at an angle of 120 ° in a clockwise manner. And moving in the opposite direction of clockwise, which is called the negative phase sequence.

It leads to a super-imposition of a negative phase sequence over the typical positive phase sequence of supply voltages when there is single phasing, phase reversal, unbalanced voltages, or no voltage in a line. This can also happen when there is an unbalanced voltage.

This negative sequence is filtered out by either a resistance-capacitance or resistance-capacitance-and-inductance network, which then de-energies the relay in the single-phasing preventer.

For the purpose of sensing the negative phase sequence, this resistance and capacitance network is utilised.

When the phase sequences and voltages are accurate, there will be no voltage difference formed across the filtered output, and as a result, there will be no relay operation.

When the negative sequence happens because of an imbalanced supply voltage or phase reversal, a voltage will build across the relay. This voltage will cause the relay to close.

Some of the single phasing preventers come equipped with the ability to make adjustments to the settings that are imbalanced.

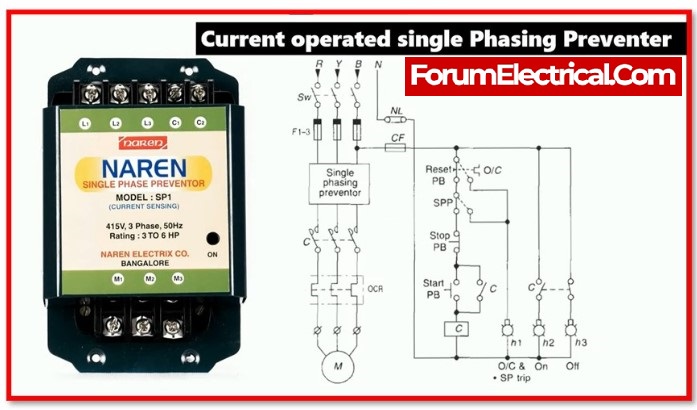

3).Current sensing Single Phasing Preventer Relay

Equal currents with balanced loads generate secondary voltage on current transformers, which is the operating principle of the current sensing single phasing preventer.

These secondary windings of the current transformer are linked to ADD, and the signal that is added is rectified, filtered, and detected before being applied to control a relay.

This relay is used to close the NVC – No Voltage Coil circuit of the starter.

When the motor starter is in its normal operating condition, the contact connection is always in the closed position.

What is the effect of the Single Phasing?

The effect of single phasing is dependent on the type of load, such as

- Heating load or

- Three phase induction motor.

1). Effect on three-phase heating loads:

The heat produced by the heating element is reduced by approximately 50%, but the equipment is not harmed.

2). Effect on three-phase motors:

If the motor fails to start because of single phasing, it is due to a lack of a proper rotating magnetic field. However, the motor draws a significant current and the motor windings become hot. As a result, the motor winding is damaged.

If single phasing happens when the motor is running, the motor may or may not run depending on the load status. The motor will draw a considerable current at that time, and the winding is likely to burn out owing to overheating.

Necessity for the single phasing preventer

If two phases of a three-phase induction motor are switched, the motor will rotate in the opposite direction. This is referred to as phase reversal. In many industrial applications, phase reversal can cause catastrophic damage to the equipment as well as injury to the user.

In other cases, if a fuse blows or a wire break while the motor is operating, the motor will continue to run on two phases but will overheat severely.

A single-phase preventer is used to protect motors from these defective conditions of phase failure.

Applications of the single-phase preventer

In general, can use this relay to protect the circuit from a variety of different types of breakdowns, including the following:

- Overvoltage,

- Undervoltage,

- In terms of frequency,

- Under (below) frequency,

- Asymmetry,

- Phase failure,

- Improved essential electrical equipment protection.

- Extremely powerful (heavy duty)irrigation water pumps.

- Any three-phase industrial load.

- Drive motors for industrial use.