- What is Electric Motor Efficiency?

- Motor Efficiency Symbol

- Motor Efficiency Formula

- Basic Motor Parts

- Losses in Motor

- How to improve the Motor Efficiency?

- 1). Frame-Covered Motor

- 2). Maintain Motor Location Clean

- 3). Increase Stator Winding Mass

- 4). Reduce Motor Slip

- 5). Enhance Copper Quality

- 6). Reduce Lamination Thickness

- 7). Insulate Properly

- 8). Electrical Overload Protection

- 9). Regular Inspection

- 10). Maintain Cool Temperature

- 11). Monitor Vibration

- 12). Using Variable Speed Drives

- Motor Efficiency Class

- What makes a Motor High Efficiency?

- Methods to Improve Motor Efficiency

- Standards followed to Increase Motor Efficiency

- Which type of Motor is more Efficient?

- What is a Good Motor Efficiency?

- Calculators

Electric motors are used in a variety of applications, including home appliances and industrial applications. So, the efficiency of the electric motor impacts how effectively the appliance performs.

Electric motors consume more electrical power than any other type of technology in industrial & commercial applications,

What is Electric Motor Efficiency?

The efficiency of an electric motor is calculated by the ratio of shaft output power to electrical input power.

This is denoted by the symbol “η” and expressed as “%”. This is the factor that indicates the performance of the motor.

Motor efficiency is calculated by dividing motor output power by motor input power.

Motor Efficiency Symbol

Motor efficiency is represented by the symbol eta= η

Motor Efficiency Formula

Efficiency (η) = (Output / Input) x 100

(or)

Efficiency = η = (Input – Losses)/Input

Ideally, the motor’s efficiency should be around 75% of its rated load.

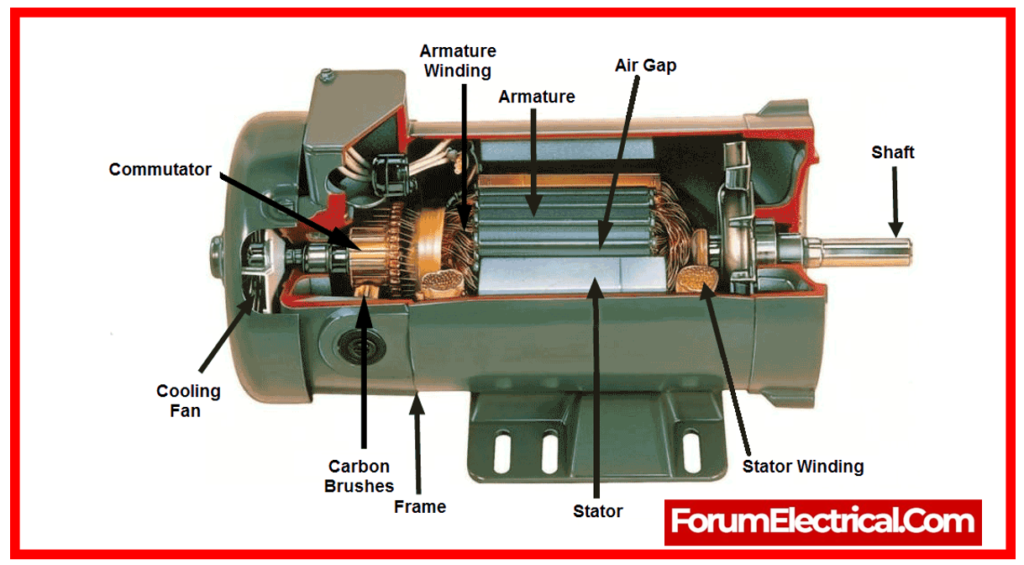

Basic Motor Parts

Major motor parts are as follows:

1). Rotor

2). Stator

3). Air Gap

4). Commutator

1). Rotor

The rotor is the moving and essential component of the electric motor. It is responsible for rotating the shaft in order to generate mechanical energy.

2). Stator

One of the stationary components of the motor is called the stator, and it either has a fixed magnet (or) a small number of windings. To reduce the amount of material that is lost, its primary core is constructed using numerous laminations or sheets of various metals.

3). Air Gap

The term “air gap” refers to the very small space that exists between the stator and the rotor.

The space that exists between these two components is required to present; however, it must be as small as it can possibly be; otherwise, it will have a negative impact on the performance of the motor.

4). Commutator

The commutator is primarily concerned with the way in which the input is switched to the DC motor itself. It is made up of slip rings that are isolated from one another as well as from the shaft.

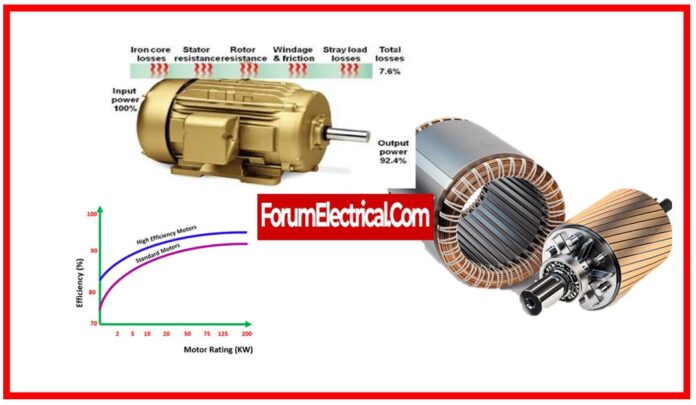

Losses in Motor

A few losses affect the motor’s efficiency, including:

- Resistance loss,

- Mechanical losses from friction,

- Losses caused by magnetic energy dissipation in the core, as well as losses that vary based on the material utilized.

To increase a motor’s efficiency, we must reduce its losses.

How to improve the Motor Efficiency?

Here are a few steps or procedures for improving motor efficiency.

Let’s discuss 8 steps to improve electric motor efficiency.

1). Frame-Covered Motor

2). Maintain Motor Location Clean

4). Reduce Motor Slip

5). Enhance Copper Quality

6). Reduce lamination Thickness

7). Insulate Properly

8). Electrical Overload Protection

9). Regular Inspection

10). Maintain cool Temperature

11). Monitor Vibration

12). Using Variable Speed Drives

1). Frame-Covered Motor

The frame of a motor is designed to give mechanical protection to winding. It also controls the interface for the installation by feet.

The motor frame is essential to its thermal performance since it transfers heat generated within the motor to the frame surface, where air blown by fan facilitates heat dissipation. It will reduce heat loss.

2). Maintain Motor Location Clean

One more fundamental point of guidance is to ensure that there is a minimum gap between any walls that are located on the back of the fan cover in order to allow air to enter.

Make sure that the area around the motor is clean, and inspect it on a regular basis for any air blockages that could potentially limit the efficiency of the cooling system.

Therefore, the longer a motor is allowed to run at a cool temperature, the longer its lifespan will be.

3). Increase Stator Winding Mass

Because the stator, which is a significant component of the motor, is responsible for 60% percent of the losses, it is necessary to maintain an increased mass of the stator winding in order to lower these losses.

This is because an increase in mass will result in a reduction in electrical resistance.

When compared to motors that are intended for normal efficiency models, motors that are extremely efficient include an additional 25 percent of copper.

4). Reduce Motor Slip

It is also important to note that rotor losses are considered to be a secondary source of losses, which are primarily caused about by the degree slip that the motor exhibits.

The difference in revolutions per minute (RPM) between the speed of magnetic field & the actual RPM of the rotor & shaft when the load is applied is what is known as slip.

Where slip is calculated by subtracting the speed of the motor when it is under load from speed of the motor when it is not under load and then dividing that number by the speed of the motor while it is under load.

Therefore, in order to lessen the impact of these losses, slip must be minimized, and this can be accomplished by increasing the conductivity of the rotor.

5). Enhance Copper Quality

Due of the high conductivity of copper, it is imperative that copper be utilized extensively. Copper, on the other end, must be die-cast since, in recent times, technologies have been created for die casting copper.

Hysteresis is the source of

- Core magnetic losses

- Eddy currents &

- Saturation of the magnetic core

are responsible for twenty percent of the overall losses on account of saturation.

Losses can be reduced to a minimum in order to achieve greater efficiency through the utilization of materials of high quality and quality control.

Therefore, in order to lessen the impact of hysteresis and saturation, steels that include a small percentage of silicon should be utilized in laminations rather than carbon steels, which are more affordable.

It is possible to eliminate core losses in this way.

6). Reduce Lamination Thickness

It is possible to minimize the flux density as well as core losses by increasing the length of the lamination while simultaneously decreasing the thickness of the lamination sheet.

7). Insulate Properly

Ensure that there is adequate insulation between the sheets (or) laminations that are being used in order to significantly reduce the amount of eddy current losses.

The lubrication interval is determined by

- The rated speed of the motor mounting,

- The size of the bearing,

- The formulation of the grease, and

- The rise in temperature.

Therefore, caution should always be used when using lubricants. Do not combine different kinds of grease, even if they contain the same components.

It is important to note that the performance of the motor will be directly impacted if another type of grease is utilized in the application.

8). Electrical Overload Protection

Electrical overload (or) over-current occurs when the motor’s designed current capacity is exceeded.

The most typical reason of this is a low voltage supply, which leads the motor to demand additional current in order to maintain torque. However, it may also be induced by short-circuited conductors or an overvoltage supply.

Installing good over-current protection can identify overcurrent before it becomes an issue, halting the supply and guarding from overload.

This will allow the motor to perform at peak efficiency while lowering the likelihood of a breakdown.

9). Regular Inspection

The most prevalent reason for motor failure is low resistance.

This occurs when the insulation of the windings degrades due to adverse conditions such as overheating, corrosion, or physical damage, resulting in insufficient isolation among windings, leakages, short circuits, and, eventually, motor failure.

Regularly inspecting the insulation for signs of wear will assist to maintain the electric motor running at peak efficiency and avoid low resistance from causing machine failure.

10). Maintain Cool Temperature

Overheating causes about 55% of insulating motor failures, thus the advantages of keeping your motor cool are apparent.

Every 10° Celsius increase in a motor’s temperature reduces insulating life by half.

The simplest technique to keep a motor’s temperature under control is to keep the operating environment cool.

This will assist you avoid failures and improve the efficiency of the electric motor.

11). Monitor Vibration

Vibration in electric motors is frequently generated by an uneven (or) unstable surface. However, it could also be caused by a root cause, such as

- Loose Bearings,

- Corrosion, or

- Misalignment.

It is essential to monitor vibration levels, as excessive vibration may cause the motor to fail prematurely.

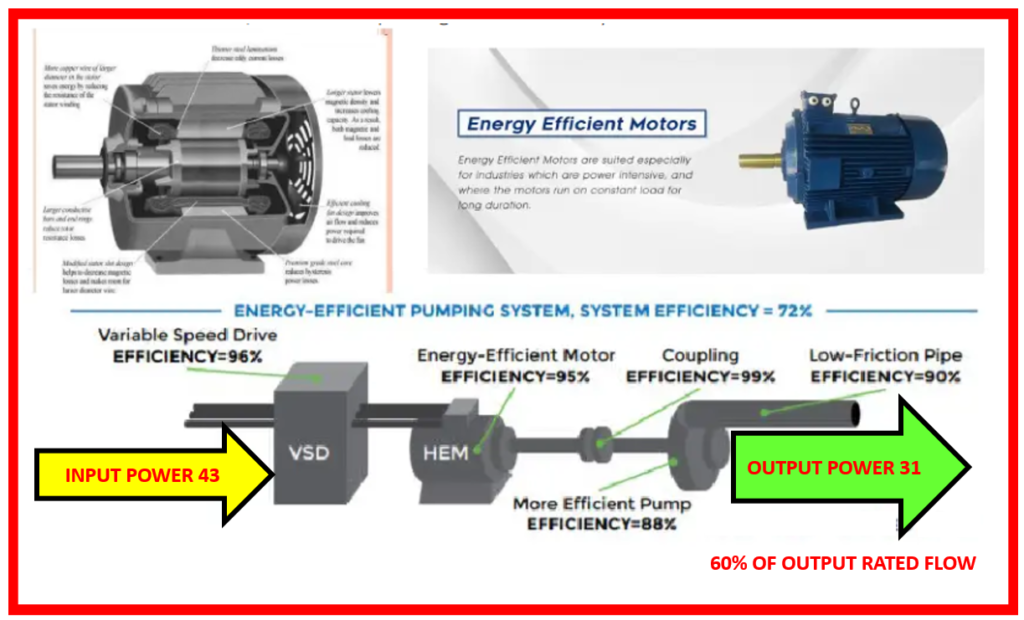

12). Using Variable Speed Drives

Variable-speed drives (VSDs) (or) adjustable-speed drives are large industrial electric motors. Their speed can be modified using an external controller.

These drives are utilized in process control because they enable to conserve energy in factories with several electric motors.

VSDs are often used as energy savers in pump & fan appliances because they improve process operations, particularly where flow control is required.

They also have soft-start characteristics, which reduce electrical strains and line voltage sags that are common during voltage motor start-ups, especially when driving high-inertia loads.

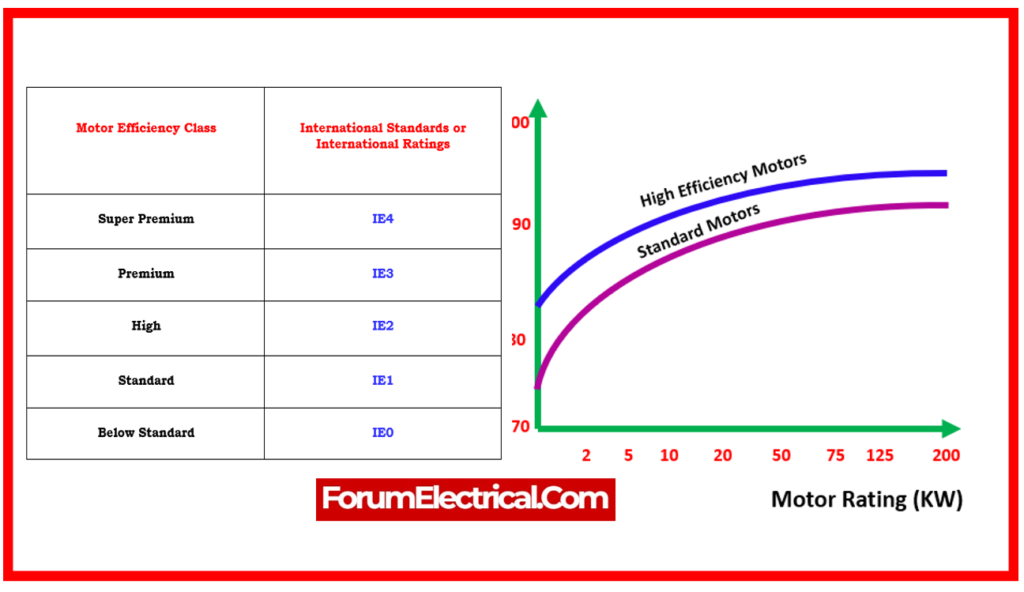

Motor Efficiency Class

| Motor Efficiency Class | International Standards or International Ratings |

|---|---|

| Super Premium | IE4 |

| Premium | IE3 |

| High | IE2 |

| Standard | IE1 |

| Below Standard | IE0 |

What makes a Motor High Efficiency?

Electric motor losses are dispersed through heat, vibration, and noise.

The mechanical & electrical design of high-efficiency motors is optimized, resulting in

- Fewer temperature rises,

- Cooler running,

- Lower temperatures in stator windings & bearings, &

- Reduced noise.

Methods to Improve Motor Efficiency

The motor efficiency plan should be broken into three parts.

- Assessment

- Improvement

- Prolong Life Span

The first stage will be to regularly monitor and document which motors are under the supervision, how old they are, how much horsepower they provide, and their ratings, as well as the controls level in your facility and the loads. Use an efficiency calculator.

Voltage imbalance and power factor are the three most crucial factors to check. Voltage & current unbalance are created by differences in values in a three-phase system.

While power factor (PF) is generally generated by motors & other heavy accessories such as transformers.

Power Factor (PF) is a percentage (or) a number, with 100% or 1 being the optimal value.

Power factor is defined as the ratio of actual (working) power (kW) to apparent (total) power in KVA, which is a combination of real and reactive power. Bad power factor can lead to an increase in electric utility expenses; hence it must be regulated.

If any problems arise with any of these factors, they must be addressed promptly. Utilizing software to estimate motor efficiency can be beneficial.

It is important to note that all of the factors mentioned must be considered when selecting a motor & making it operational. Furthermore, to extend the life of the motor, inspections should be performed at regular intervals.

Some motor analysis tools are utilized for monitoring an electric motor’s vibration and temperature. This can help to make sure that the motor operates at peak efficiency and reduces the danger of early motor failure.

Standards followed to Increase Motor Efficiency

Improving motor efficiency is an important component of energy saving, and various standards exist to help guide and govern the design, manufacture, & usage of efficient motors.

Compliance with these criteria helps to make sure that motors run at peak efficiency, decreasing energy consumption & environmental effect.

Here are some essential benchmarks for motor efficiency:

- This set of standards, established by the IEC, specifies the design and performance of spinning electrical equipment, including motors. IEC 60034-30-1 focuses on motor efficiency classes.

- The NEMA MG 1-2018 standard specifies the manufacturing & performance characteristics of motors and generators. It contains recommendations for testing motor efficiency & efficiency charts for various motor types.

- ISO 50001 is an international standard that outlines the steps for developing, implementing, maintaining, & improving an energy management system. While it is not particular to motors, it can be used to control and increase energy efficiency in an organization’s motor-driven systems.

- The ANSI C50.20 standard contains standards for distribution equipment, that may include motors. It establishes standards for efficiency, temperature rise, & other performance metrics.

- Underwriters Laboratories (UL) Standard 1004-1 specifies standard requirements for rotating electrical devices, including motors. Performance with this standard assures that motors satisfy safety and performance specifications.

When selecting and operating motors, it is essential to analyze the relevant standards and regulations to make sure that the selected motors meet or surpass the specified efficiency levels. Furthermore, continued developments in technology & energy efficiency may result in upgrades or adjustments to these requirements over time.

Which type of Motor is more Efficient?

A DC motor tends to be more efficient than an AC motor because it makes better use of the input energy. An AC motor, on the other end, may generate more torque by utilizing more strong currents, making it the more powerful.

What is a Good Motor Efficiency?

A rated load of 50% to 100% is the operating range for most types of electric motors. Typically, maximum efficiency is close to 75% of the rated load. Therefore, the allowable load range for a 10-horsepower (HP) motor is 5 to 10 hp, with a peak efficiency of 7.5 HP.

Calculators