What are an Electrical Connectors?

Electrical connectors are electro-mechanical parts that connect electrical circuits. It consists of

- A fixed female contact (socket) and

- A free male contact (plug).

There are circular electrical connectors and rectangular electrical connectors based on form, and each kind may be further separated depending on the connecting technique.

It should be carefully analysed each electrical connector’s criteria, which include the

- Electrical,

- Safety,

- Mechanical, and

- Environmental ones, before choosing one.

Electrical connections will continue to develop in various areas in the future, notably in high-speed transmission.

This post outlines the specification and characteristics of the electrical connectors in detail.

Specifications of Electrical Connectors

When choosing electrical connections, there are a number of certain elements that, depending on the specific type of connector and the application for which it will be used, may be essential to take into consideration.

The specifications of an electrical connectors indicate the conditions under which it is intended to function.

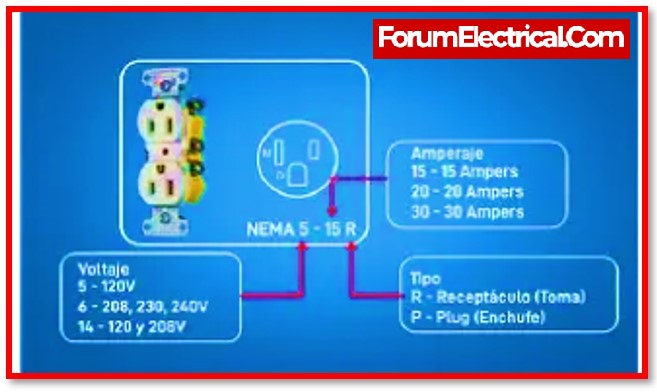

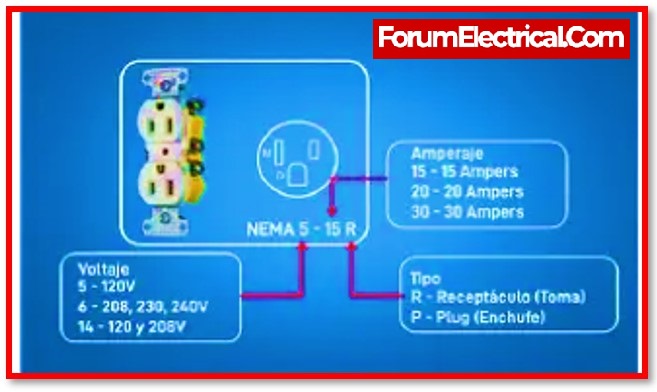

- Connectors current rating refers to the amount of current (rate of electricity flow) that a connection is intended to carry, which is measured in amperes or amps (A). Connector current ratings typically vary from 1 A to 50 A.

- Voltage defines the connector’s voltage rating in volts (V). The most common ratings are 50 V, 125 V, 250 V, & 600 V.

- The operating temperature defines the electrical connector’s suggested, range, or minimum/maximum the operating temperature (s).

Characteristics of Electrical Connectors

Physical parameters explain the physical design of an electrical connectors.

1). Contact pitch

The distance (measured in millimeters) between closest pins or terminals of a connection (from center to center). A lower connection density (fewer pins (or) connections / area) is described by a greater contact pitch. Arcing is influenced by pitch and occurs when both conductors are in the close proximity to one another (low pitch), which results in interference.

2). Number of Contact

The number of conductive components that pair with the corresponding element to form an electrical path.

3). Materials

The components utilised to build the connectors. Connectors are commonly comprised of metal and plastic, although they may be formed of almost any conductor & insulating material.

- Conductivity,

- Mechanical strength,

- Formability, &

- Resilience

are all key properties of conducting materials for electrical connectors.

4). Gender

The gender of a connector relates to the device it plugs in or is connected into and is generally male or female. Some connectors look like female but are male.

5). Polarity

The majority of connections can only be plugged in one way. Connectors that contain a mechanism to prohibit incorrect connections are referred to look be polarised, or sometimes keyed, and this characteristic is known as polarity.

6). Mating Patterns or Mating Cycles

Connectors have a limited lifespan, and attaching and unplugging them is what wears them out. It varies greatly from technology to technology. A board-to-board connection designed for usage inside of consumer devices may be limited to tens of cycles whereas a USB connector may have a lifespan in the thousands (or) tens of thousands of cycles. One must choose a connection with a life that is appropriate for the application.

7). Mount

Mount has the potential to be perplexing. The word “mount” may refer to a number of different things, including how the connection is physically connected (solder tab, surface mount, through hole), how it is positioned respect to its attachment (straight and right-angle), and how it is placed in usage (panel mount, free-hanging, board mount).

8). Strain Relief

The electrical connectors can appear rather weak when a connector attaches to a board or wire. To transmit any stresses exerted on that junction to a more mechanically sturdy component than the delicate electrical connections, some type of strain relief is often provided.

The following table lists a few common terminal metals:

| Metal | Characteristics of Metal | Applications |

|---|---|---|

| Phosphor Bronze | Superior elasticity, outstanding fatigue resistance, and good strength, toughness, & conductibility | Springs for electrical contacts |

| Brass | Zinc composition ranges from 5 to 40%; it is the cheapest metal by the weight and has strong electrical, spring, and tensile qualities. | KK terminals |

| Copper Alloy | Modified copper with high strength, strong thermal and electrical characteristics, and resistance to softening at the high temperatures. | Applications mostly for automobiles |

| Beryllium Copper | The most expensive copper alloy for the spring terminals is much less expensive than phosphor bronze. | Applications that need maximum performance |

Features of Electrical connectors

- Electrical connectors may need to have certain qualities for some applications.

- Keyed connectors are only intended to connect in a certain direction. By doing this, the user is prevented from dropping pins or putting them in the incorrect sockets. The orientation of the pins and case prevents the plug from being placed wrongly.

- In order to avoid an accidently undone connection, locked connectors is to provide a way to secure the connection in place.

- Hermetically sealed connectors can tolerate water pressure to a certain depth and are completely functioning underwater.

- Connectors that are water resistant are designed to guard against water damage.

- Oil- and moisture-resistant connectors are intended to guard connections from harm.

- Connectors are shielded from electromagnetic interference (EMI) (and/or) radio frequency interference (RFI) by EMI or RFI filtering.

- Electrical connectors are insulated from electrostatic harm (ESD) via ESD shielded connectors.