- Inspection Checklist for Portable Power Tools

- Regular Inspection and its Importance

- Portable Electrical Power Tool Safety Guidelines

- How to store and maintain Portable Electrical Power Tool?

- When and how should Portable Hand Tools (Powered Hand Tools) be inspected?

- Portable Electrical Equipment Safety Guidelines

- Maintenance and Storage Protocols

- Attachment

- Summary

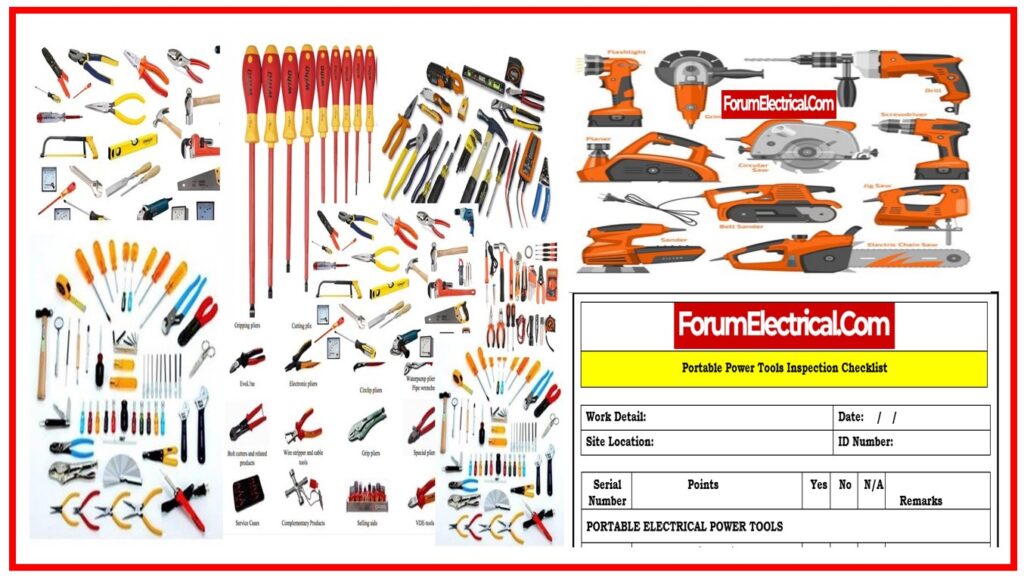

Portable power tools inspection checklists analyze the condition and safety of handheld and moveable tools used in industrial and construction locations. Tools’ operational readiness and worker safety are the primary objectives.

Inspection Checklist for Portable Power Tools

A portable power tools inspection checklist evaluates the condition and safety of handheld and moveable equipment used in industrial and construction situations.

It prioritizes worker safety and tool operating readiness.

Importance of Workplace Safety

Power tools make workplaces dangerous. These instruments are essential for productivity but contain risks that require careful handling. To prevent staff from harm, injuries, & long-term health issues, these places must be safe.

Systematic Check

Checklist-based inspections ensure tool functionality & operator safety. Tools are inspected for electrical safety, grounding, equipment condition, and operational norms. By following this method, companies can prevent hazards from escalating.

ANSI B11: For machine tool safety, the ANSI B11 series frequently provides rules for inspections & safety practices.

29 CFR 1910 Subpart S: OSHA regulates workplace electrical safety under 29 CFR 1910 Subpart S. Installations, wiring, & equipment are specified in order to protect workers against electrical hazards. Wiring design, safeguarding, hazardous areas, personnel safety, and maintenance and repair lockout/tagout procedures are all addressed.

Regular Inspection and its Importance

Keep Workplace Safe

Workplace safety relies on regular inspections. They identify and fix safety issues before they become major threats. Organizations can reduce risks and boost productivity with frequent checks.

Accident and Equipment Failure Prevention

Inspecting regularly prevents accidents and equipment failure. Inspections detect and fix problems early, preventing injuries and work disruptions. A preventive approach avoids downtime and financial costs from the unexpected tool failures.

Legislation and Regulation

Regular inspections are required under workplace safety laws. Legally protecting workers’ well-being requires compliance with these standards. Non-compliance compromises safety and exposes companies to legal consequences.

Portable Electrical Power Tool Safety Guidelines

Step- 1: Checking Tool Condition

Regularly inspect power tools before & after usage. This involves checking:

- Wear and tear

- Damaged (or) loose parts

- Proper switch and operating mechanism operation

- Blade and cutting-edge sharpness

- Possible operation overheating

Step- 2: Correct Grounding and Insulation

Power tools should be grounded or insulated to avoid electrical risks. This involves:

- Checking for three-prong grounding plugs on tools.

- Checking for exposed wire or insulation damage.

- Safely using double insulation when grounding isn’t possible.

Step- 3: Electrical Cord Safety

Check power tool cords for safety:

- Avoid utilizing tools with the damaged cords and promptly repair or replace them.

- Maintain cords without tape or modification and a working ground pin.

- Cords should not be near wet places to avoid electrical dangers.

How to store and maintain Portable Electrical Power Tool?

Store and maintain tools properly to extend their lifespan & ensure safety:

- Protect tools from moisture and damage in specific areas.

- Store tools in cases (or) coverings to avoid dust and damage.

- Following manufacturer instructions, clean, lubricate, and sharpen blades regularly.

- Provide employees with proper tool handling, storage, & maintaining them.

When and how should Portable Hand Tools (Powered Hand Tools) be inspected?

- Check tools for any damage before using them again.

- Examine the tool’s body case and handle for any cracks (or) other damage.

- Make sure the tool’s auxiliary (or) double handles are installed securely if it has any of them.

- Examine cords for faults: Look for wear indicators such as fraying or cracking in the power cord, as well as complications with the insulation.

- Look for switches that are broken or have malfunctioning trigger locks.

- Examine the plug for cracks & loose, missing, or damaged prongs.

Portable Electrical Equipment Safety Guidelines

Step- 1: Operating Switches and Guards

Equipment safety depends on operational switches and guards:

- Check and test them often to ensure they turn equipment on & off efficiently. Fix or replace broken switches immediately.

- Make that all safety guards protecting operators from the moving parts are intact, avoid blocking or tampering with these guards when using equipment.

Step- 2: Operator Safety

Protect equipment operators with extensive safety measures:

- Provide extensive equipment operating, emergency, and safe handling training. Safety can be reinforced with regular training.

- Emphasize tool-specific PPE. This includes eye, hearing, glove, helmet, and any specialist gear needed to reduce equipment dangers.

Step- 3: Different Tool Safety Precautions

Optimizing operator safety requires specific safety procedures for different equipment:

- Welding Equipment: Train & authorize qualified welders. Require welding helmets, gloves, & aprons and post warning signs to prevent unauthorized entry.

- Jackhammers: Protect operators from high impact and noise with strong footwear, eye protection, & earmuffs.

- Pneumatic Nailers/Staplers: Train operators on handling and storage. Promote muzzle safety and die clip security to prevent inadvertent firing.

Maintenance and Storage Protocols

Portable Equipment Storage Best Practices

- Equipment safety and longevity depend on proper storage:

- Store portable equipment in dry, secure, and accessible spaces.

- Prevent corrosion and damage by shielding tools from moisture, severe temperatures, and direct sunlight.

- Use cases or coverings to prevent dust and damage during storage.

- Keep tools arranged for simple identification and quick access.

Importance of Regular Maintenance

Equipment performance and lifetime depend on regular maintenance:

- Maintain a preventive maintenance program as advised by the equipment manufacturers.

- Routinely examine & lubricate moving parts for wear and tear.

- To ensure accuracy and performance, clean and calibrate equipment regularly.

- To prevent further degradation, fix (or) replaces damaged components immediately.

Attachment

Summary

The Portable Power Tools Inspection Checklist is essential for workplace safety and efficiency. Its organized method to analyzing portable electrical equipment includes safety steps to reduce tool operation risks.

Organizations can protect staff and equipment and create a safe, productive workplace by following its standards and inspecting regularly.

This overview emphasizes the checklist’s significance for workplace safety, systematic inspections, maintenance, compliance, & operator and equipment condition.