- What is a Permanent Magnet Direct Current (PMDC) Motor?

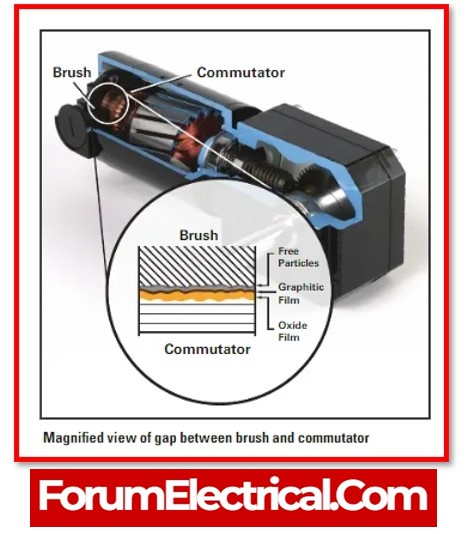

- Construction of a Permanent Magnet DC (PMDC) Motor

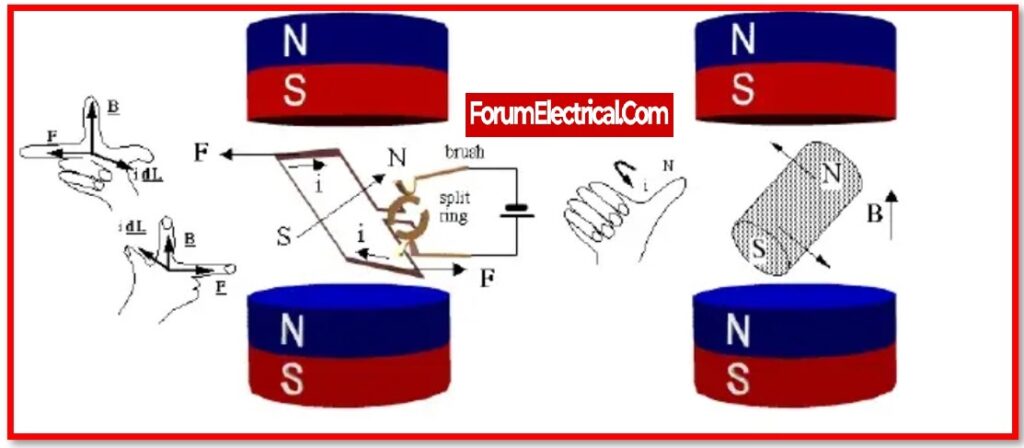

- Working Principle (Operation) of Permanent Magnet DC (PMDC) Motor

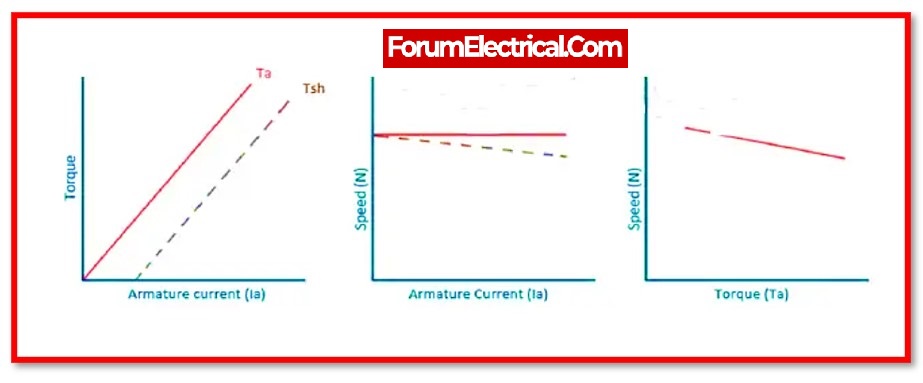

- Characteristics of Permanent Magnet DC (PMDC) Motor

- Advantages of Permanent Magnet DC (PMDC) Motor

- Disadvantages of Permanent Magnet DC (PMDC) Motor

- Applications of Permanent Magnet DC (PMDC) Motor

- What is the main difference (distinguish) between a PMDC motor and a DC motor?

- Which type of motor is better, PMDC or BLDC?

- Which type of motor provides better speed regulation: PMDC or DC shunt?

- Difference between PMDC motor and BLDC motor

- PMDC motor vs BLDC motor

- Conclusion

Electric motors use electricity to generate motion. Motors are essential in a wide range of activities, from industry to transportation & even toys.

A permanent magnet DC motor, like an induction motor, is an advanced form of motor. It generates torque by using the fundamental of electromagnetic principles.

The magnetic field for running the DC motor is created by a permanent magnet, as the name implies.This post provides an overview of the PMDC (Permanent Magnet DC) motor.

What is a Permanent Magnet Direct Current (PMDC) Motor?

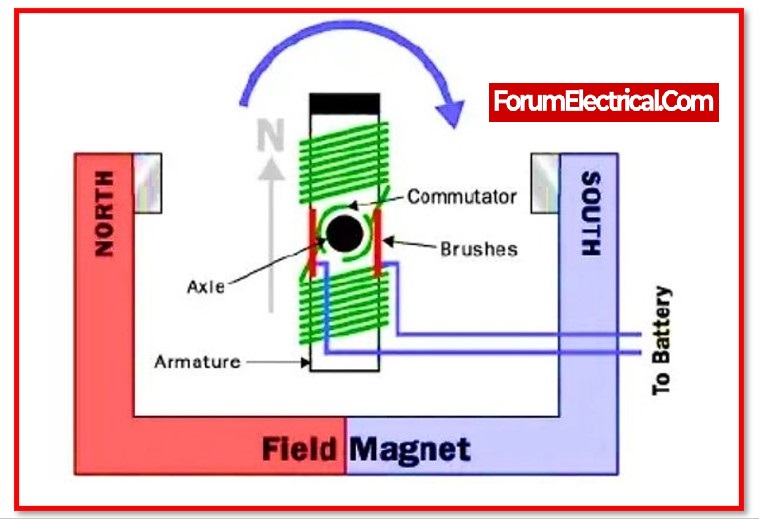

A PMDC – Permanent Magnet DC motor is one that has a permanent magnet pole. With this motor, the magnet may be utilised in instead of the field winding to make the flux operate inside the air gap. The rotor construction is similar to that of a direct current motor.

The rotor of a PMDC motor contains the

- Armature core,

- Commutator, and

- Armature winding.

Typically, there are two types of winding in a normal DC motor:

- Armature windings and

- Field windings.

The primary role of field winding is to generate working magnetic flux inside the air gap and is wound on the stator of the motor, while armature winding is wrapped on the rotor.

Like with a regular DC motor, in-active carbon brushes are pushed against the commutator. The voltage sources provide a 6V, 12V, or 24 V DC supply for the PMDC motor’s operating voltage.

Construction of a Permanent Magnet DC (PMDC) Motor

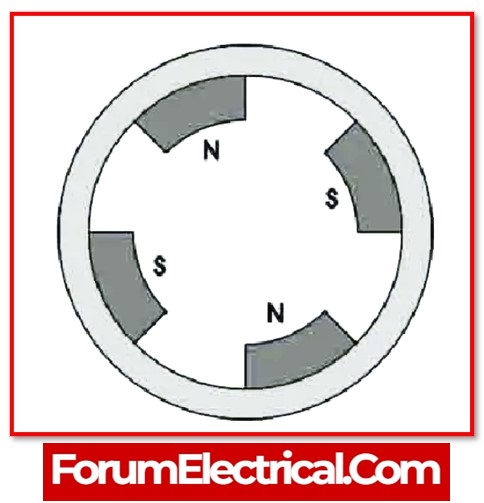

1). Stator

The stator is the outermost component of the PMDC motor that serves as its housing.

The North and South poles of magnets are arranged such that they alternately face the armature on the inner (internal) side of the stator.

The stator, in addition to holding the magnets, acts as a low resistance return channel for the magnetic flux.

In the condition that the magnets lose their power, an alternative additional field coil is given to compensate.

2). Armature

The armature comprises the

- Winding,

- Core, and

- Commuter and

is connected to the output shaft of the PMDC motor.

Some motors use a DC power supply or induction to produce their own magnetic field.

In certain conditions, it is merely a ferromagnetic metal. PMDC motors, on the other end, use a different mechanism.

The armature’s core is made up of slotted circular steel sheet laminations that are varnish insulated. The steel sheets serve to decrease rotor eddy current loss.

The armature is made up of slots that hold armature winding. The brushes will provide current to the armature’s commuter.

The electrical power will subsequently be converted into motion. Connecting (linking) the brushes terminals to the DC supply powers the armature.

The PMDC motor is classified as synchronous because the magnets inside it can achieve speeds that is equal to the excitation current.

3). Magnets for PMDC motors

Magnets utilised in PMDC motors are made of three different materials.

- Alnicos magnets

- Ferrite magnets and

- Rear earth magnets

a). Alnicos magnets

Alnicos are distinguished by their high residual flux density & low coercive magnetising intensity. As a result, they are typically employed in applications requiring a low current at a high voltage.

b). Ferrite magnets

Ferrite magnets are less expensive and are employed in PMDC motors for cost sensitive applications such as

- Refrigerators,

- Air conditioners, and

- Compressors.

c). Rear earth magnets

Rear earth magnets are made of

- Neodymium,

- Iron, and

- Boron or Samarium cobalt.

They have a high residual flux and a high coercive magnetising intensity. These magnets are not demagnetized as a result of armature reactions.

Materials for rear earth magnets are often fairly costly. Neodymium iron boron is less expensive than samarium cobalt and can endure high temperatures.

PMDC motors with rear earth magnets are utilised in size-sensitive applications such as

- Autos,

- Servo industrial drives, and

- Big industrial motors.

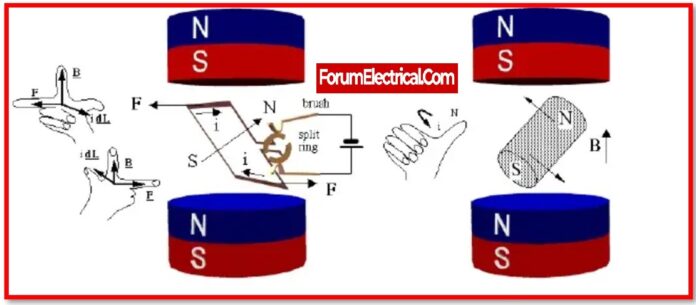

Working Principle (Operation) of Permanent Magnet DC (PMDC) Motor

A permanent magnetic field may be established in this motor by using permanent magnets that communicate through a perpendicular field triggered by the flow of currents inside the rotor windings; therefore, mechanical torque can be generated.

When the rotor spins in response to the torque, the location of the stator and rotor fields is decreased, and the torque is reversed in a 90 ° rotation. PMDC motors feature a commutator connected to the rotor shaft to maintain torque on the rotor.

The commutator directs the current supply towards the stator, maintaining a constant angle of 90 ° between two fields. Since current flows are regularly triggered among windings, such as rotor twists, the current inside each stator winding is effectively exchanging at a frequency proportional to the number of motor magnetic poles and as well as the speed.

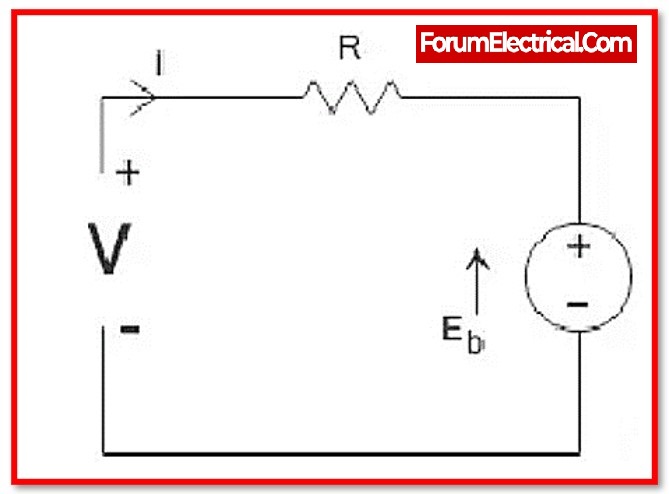

There is no requirement to draw field coils within the PMDC motor equivalent circuit since the permanent magnet in a PMDC motor may provide the field.

The voltage supply (V) to the armature will include armature resistance fall as well as voltage supply break may be addressed using the motor’s back e.m.f.

As a result, the motor’s voltage equation is given by,

V = IR +Eb

Where,

I represent armature current.

R represents armature resistance.

Eb represents back emf.

V represents supply voltage.

Characteristics of Permanent Magnet DC (PMDC) Motor

In terms of speed, torque, and armature current, PMDC motor characteristics are similar to dc shunt motor characteristics. Additionally, the speed-torque characteristics of these motors are more linear and typical.

The flux control method cannot be used to control the speed of a permanent magnet DC motor since its magnetic flux is constant.

As a result, speeds over the basic speed are not possible with PMDC motors. As a result, these motors are used in conditions where motor speeds lower than the basic speed are needed.

Advantages of Permanent Magnet DC (PMDC) Motor

- Since PMDC motors do not need field winding, they do not experience from field-circuit copper loss.

- PMDC motors are more efficient than traditional DC motors.

- Since field winding is not needed in PMDC motors, these motors are smaller in size than traditional DC motors.

- Since permanent magnets generate the magnetic field, PMDC motors do not need a field excitation system.

- Regarding fractional kW rated applications, PMDC motors are less expensive and more cost effective.

Disadvantages of Permanent Magnet DC (PMDC) Motor

- The electromagnetic torque generated per ampere in a permanent magnet DC (PMDC) motor is lower because permanent magnets cannot provide large flux densities.

- The magnetic poles are at risk of becoming less magnetic, which might be brought on by high armature currents or severe heating from sustained overloading.

- Even when a PMDC motor is not in operation, its magnetic field is always present. In order to prevent damage to the motor, it should be completely encased so that no outside magnetic material is drawn to the permanent magnets.

- Since the armature reaction in a PMDC motor cannot be controlled, the magnetic field’s intensity may weaken as a result of the armature reaction’s demagnetizing effects.

- It is complicated to regulate the speed of the PMDC motor since the field flux remains fixed in the PMDC motor.

Applications of Permanent Magnet DC (PMDC) Motor

- PMDC motors are used in a variety of applications ranging from fractions to hundreds of horsepower. They have a capacity of 200 kW and are intended for usage in a variety of sectors.

- PMDC motors are used in vehicles to power wipers and washers, raise and lower windows, and drive blowers for heaters and air conditioners.

- Computer drives use PMDC motors.

- PMDC motors are widely utilised in the toy industry.

- Electric tooth brushes employ PMDC motors.

- Used in vacuum cleaners.

- Used in food processors or mixer.

- Also seen in portable electric equipment including drills, saws, and trimmers.

What is the main difference (distinguish) between a PMDC motor and a DC motor?

As compared to DC motors that are more traditionally used, PMDC motors offer a better efficiency. As a result of the absence of field windings in PMDC motors, their dimensions are much more compact than those of traditional DC motors. Since permanent magnets are responsible for producing the magnetic field, PMDC motors do not need any kind of field excitation system to function.

Which type of motor is better, PMDC or BLDC?

As compared to a BLDC motor, a PMSM motor generates a greater amount of torque. The efficiency (performance) of a BLDC motor is lower, ranging anywhere between 85% and 90%. When the switching frequency is held constant, a BLDC motor has lower switching losses. Switching losses in PMSM motors are often rather significant.

Which type of motor provides better speed regulation: PMDC or DC shunt?

PMDC provides better (superior) speed control compared to DC shunt motors. As compared to dc shunt motors, PMDC motors provide improved speed control and efficiency.The primary problem with a dc shunt motor is that it will run away when the field connections (field terminals) are opened.

Difference between PMDC motor and BLDC motor

PMDC motor vs BLDC motor

| S.NO | PMDC MOTOR | BLDC MOTOR |

|---|---|---|

| 1 | Brushed permanent magnet DC motors are another term for PMDC motors. | Brushless permanent magnet DC motors, also known as BLDC motors. |

| 2 | Commutation in PMDC motors is accomplished mechanically via the use of brushes and a commutator. | Electronic commutation is used in BLDC motors, and it is commonly accomplished by Hall effect sensors located on the stator. |

| 3 | Permanent magnets are used in the construction of the stator in PMDC motors. | BLDC motors use permanent magnet rotors. |

Conclusion

Thus, this summarizes everything about PMDC motors. Toys, washers, automotive starters, windscreen wipers, computer disc, air conditioners, hot blowers, etc. are all examples of applications where minute motors are required yet very efficient control is not adequate .