- What is Electrical Maintenance?

- Induction Motor Maintenance

- Induction Motor Routine Maintenance

- Induction Motor Preventive Maintenance

- Induction Motor Breakdown Maintenance

- Induction Motor Predictive Maintenance

- Need for Electrical Equipment Maintenance

- Advantages of Equipment Maintenance

- What is Preventive Maintenance of Induction Motor?

- How do you check Motor Maintenance?

- What is the method of maintenance of a three-phase induction motor?

What is Electrical Maintenance?

Electrical maintenance includes all phases of testing, monitoring, repairing, and replacing components of an electrical system. Electrical maintenance is typically done by a licensed professional with a comprehensive knowledge of National Electric Code & local rules. It encompasses sectors that include as:

- Digital Communication

- Electrical Machines

- Generators,

- Hydraulics,

- Lighting Systems,

- Pneumatics,

- Surge Protection, And

- Transformers.

With more focus on data collecting and computer-controlled machinery, electrical maintenance is more essential than ever. The failure of one electrical component might result in significant downtime or data loss.

Induction Motor Maintenance

Induction motors must be maintained in order to avoid breakdowns and operate reliably. Induction motors require regular inspections, cleaning, & component replacements. Common maintenance procedures for induction motors include the following:

- Induction Motor Routine Maintenance

- Induction Motor Preventive Maintenance

- Induction Motor Breakdown Maintenance

- Induction Motor Predictive Maintenance

Induction Motor Routine Maintenance

The key element of a routine maintenance program is maintenance, which is typically performed every day.

One of the easiest types of maintenance to perform, routine maintenance is quick and easy to complete.

The primary components of routine induction motor maintenance are:

- Dust is cleaned by blowers.

- Recording voltage and current at the load.

- Checking the noise level, vibration, temperature, and so on.

- Verifying the earth connection.

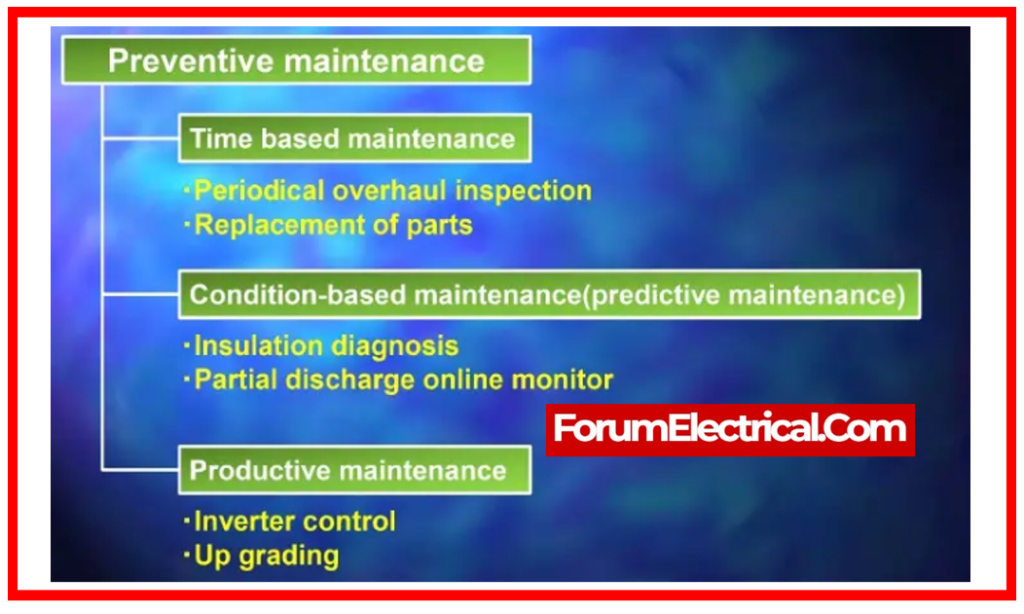

Induction Motor Preventive Maintenance

It is a scheduled and well-organized maintenance routine that is carried out in order to prevent a major system failure.

Preventive maintenance involves scheduling maintenance that might be performed weekly, monthly, quarterly, yearly, twice yearly, or five times a year.

Preventive maintenance of an induction motor involves inspecting loose parts.

Inspect the ventilation system.

Oiling & greasing the motor.

Replace worn out parts or make repairs as needed.

The maintenance program prevents significant failures and equipment breakdowns.

Advantages of Preventative Maintenance

- Reduced periods of equipment downtime

- The number of interruptions to essential operations is reduced.

- Longer life span of the motor

- The efficiency of motors that are in good repair tends to be improved, resulting in improved efficiency.

- Obtained a higher level of compliance with OSHA regulations and enhanced workplace safety

Induction Motor Breakdown Maintenance

This type of maintenance must be performed immediately in the case of an occurrence breakdown fault.

A breakdown can occur owing to a short circuit defect in the winding, an earth fault, or a failure of the bearings. in rotating machines, etc.

In this kind of maintenance, quick steps are made to rectify the fault, such as rewinding if the winding is burnt out (or) replacing faulty parts promptly after inspection to prevent further breakdown.

- The tightness of stationary portions is tested.

- It is also checked to ensure that the movable parts are free to move & have not been damaged.

- Cause for the fault that can be eliminated.

- Atmospheric conditions and the settings in which the machine will work.

Induction Motor Predictive Maintenance

This type of maintenance predictability involves using a routine or preventive maintenance schedule.

According to the working conditions, a schedule must be created to avoid a machine failure. This schedule also aids in maintaining the machines well for operation without disrupting output.

The skilled person makes predictions based on the preventive schedule to avoid serious equipment damage.

It includes temperature checks, insulation checks, noise levels, vibration checks, bearing checks in the case of rotating machinery, and so on.

Predictive maintenance approaches are intended to assist in determining the state of in-service equipment and estimating when maintenance should be conducted.

The primary objective of predictive maintenance is to enable easier scheduling of corrective maintenance and to prevent unexpected equipment failures.

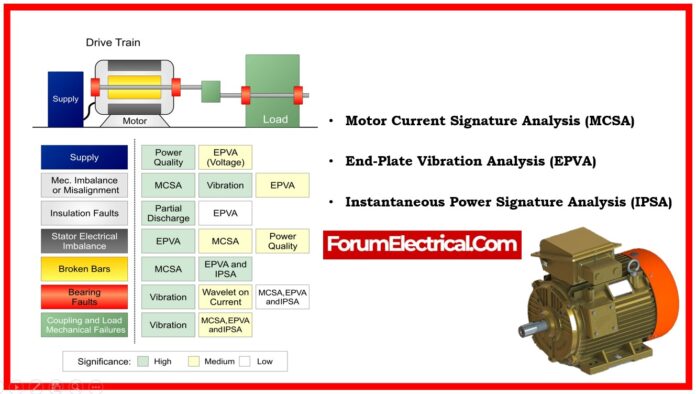

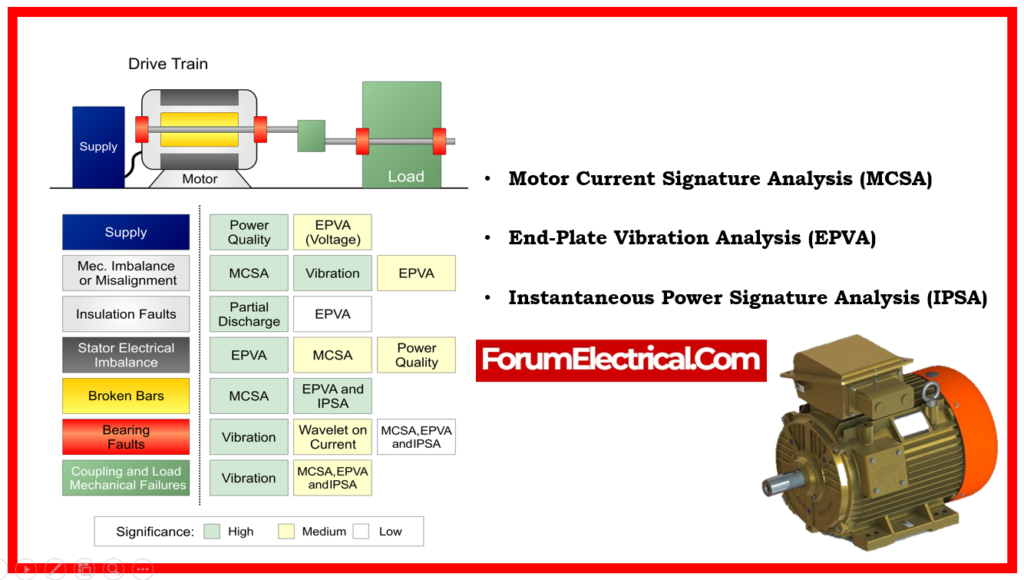

IPSA in Induction Motor

The Instantaneous Power Signature Analysis (IPSA) technology was utilized to identify the faults. It provides a comprehensive analysis of the suggested technique, as well as experimental findings for healthy and malfunctioning motors.

MCSA in Induction Motor

Motor Current Signature Analysis (MCSA) is a condition monitoring approach for diagnosing faults with induction motors. The concept originated in the early 1970s and was originally proposed for utilization in nuclear power plants for inaccessible & hazardous motors.

EPVA in Induction Motor

EPVA, or End-Plate Vibration Analysis, is a diagnostic tool for evaluating the state of induction motors. This approach detects potential flaws such as bearing defects, rotor imbalance, misalignment, or looseness by measuring vibrations at the motor’s end plates.

Vibration sensors are used to measure these vibrations, & advanced signal analysis is used to detect unusual patterns. EPVA offers early diagnosis of motor faults, allowing for proactive maintenance to avoid downtime & costly repairs.

Need for Electrical Equipment Maintenance

Equipment maintenance is a valuable requirement. Here are some of the long-lasting advantages of equipment maintenance, which is necessary:

- Extend the life of equipment and reduce the requirement for new purchases.

- Prevent unplanned downtime, which can be costly and disrupt the manufacturing process.

- Avoid costly repairs due to neglect.

- Keep equipment operating continuously to make sure that projects are finished on time and within expense.

- Ensure that systems are running efficiently in order to reduce energy usage and operational costs.

- Prevent minor faults from escalating into major ones that are time-consuming & costly to resolve, as complex repairs frequently come with a higher price tag and lengthier downtime.

- A proper service record increases the equipment’s resale value.

- Increase equity & borrowing power by protecting the value of the assets.

- Reduce injuries & fatalities, as well as liability, caused by malfunctioning equipment.

- To maximize warranty coverage, keep complete service records that verify that maintenance is up-to-date.

Advantages of Equipment Maintenance

- Increase component operating life and availability.

- Provides for corrective actions.

- A reduction in equipment (or) process downtime.

- Lower expenses for components and manpower.

- Improved product quality.

- Increased workplace and environmental safety.

- Increased worker morale.

- Energy savings.

- Estimated cost savings of 8% to 12% over preventive maintenance schedule.

What is Preventive Maintenance of Induction Motor?

Preventive maintenance is carried out on a regular basis to ensure that the motor operates properly, as well as to perform procedures (modifications, lubrication, correction, etc.) and replace parts suggested by the manufacturer depending on the motor’s workload.

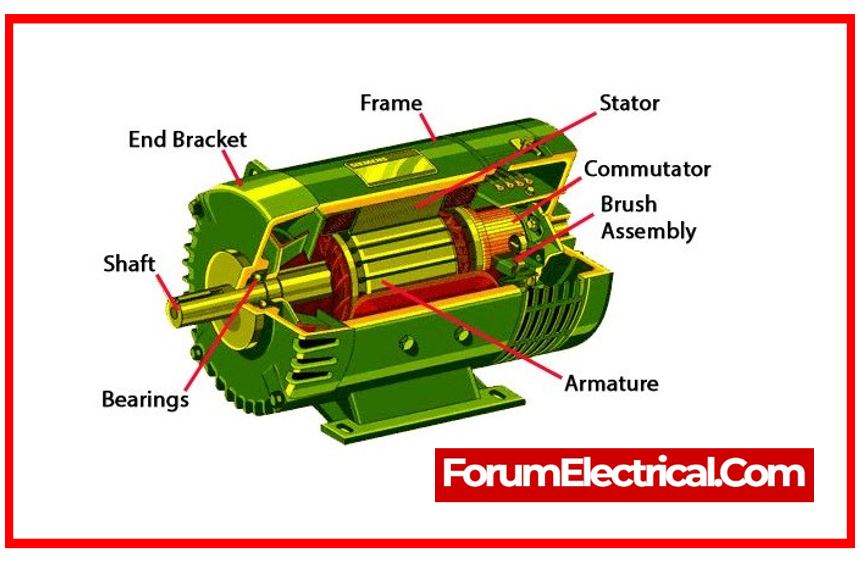

How do you check Motor Maintenance?

7 Guidelines for Better Electric Motor Maintenance

- Perform visual inspections.

- Perform a brush & commutator inspection.

- Perform a motor winding test.

- Check the bearings.

- Perform vibration tests.

- Use Infrared Thermography for Predictive Maintenance.

- Document everything.

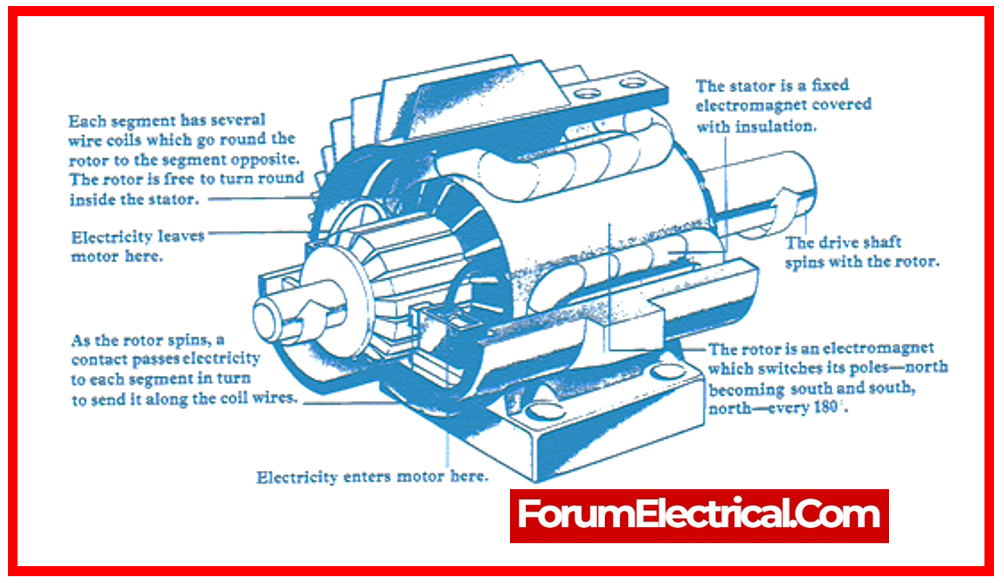

What is the method of maintenance of a three-phase induction motor?

- Check to ensure that the motor’s frame (or) terminal box is grounded. Insulation Resistance.

- Test the stator & rotor windings using their terminal connectors.

- To test stator windings less than 3KV, utilize a 500V testing instrument.

- Stator windings rated above 3KV should be tested using a 1000V device.