1. What is a synchronous motor, & how is it different from other types?

A synchronous motor is an AC motor that runs at a constant speed specified by the power supply frequency and the number of poles. Synchronous motors, unlike induction motors, operate at synchronous speed with no slip.

2. What are the most common uses for synchronous motors?

Synchronous motors are used in a variety of applications, including

- Industrial drives,

- Power generation

- Power factor correction synchronous condensers, and

- Precise motion control systems.

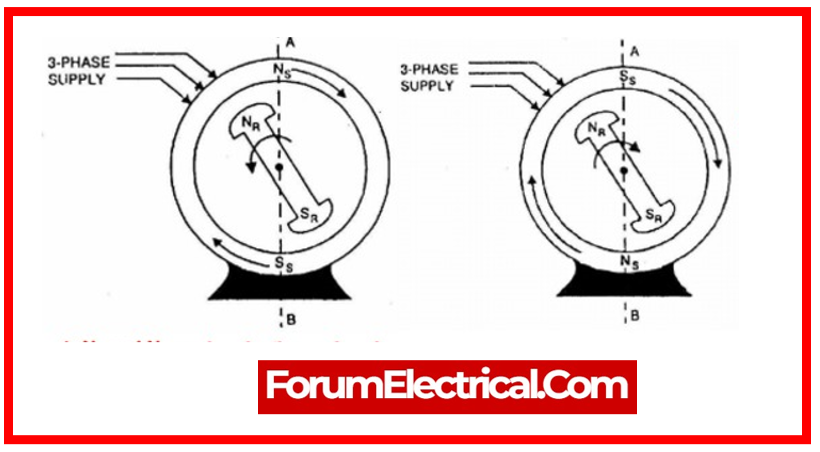

3. How does a synchronous motor maintain power supply synchronism?

Synchronous motors sustain synchronism since the rotor rotates (rotation) at the same rate as the stator’s rotating magnetic field.

4. What factors influence synchronous motor speed?

A synchronous motor’s speed is proportional to the frequency of the power source and inversely proportional to the number of poles in motor.

5. Does synchronous motors effectively manage fluctuating loads?

Because of their set synchronous speed characteristics, synchronous motors remain less efficient at handling varying loads than induction motors.

6. What occurs if a synchronous motor’s synchronism is lost?

When a synchronous motor lose synchronism with the power source, it stops working efficiently and may need to be re-synchronized before it can be restarted.

7. How do synchronous motors get going?

Auxiliary devices such as damper windings (or) starting motors are commonly used to get synchronous motors up to synchronous speed prior synchronizing with the power source.

8. What advantages do synchronous motors have over induction motors?

In comparison to induction motors, synchronous motors provide greater

- Power factor correction,

- Higher efficiency under constant load, and

- Precision speed control.

9. Are synchronous motors run at various speeds without being modified?

To run at varying speeds, synchronous motors need external control systems such as variable frequency drives (VFDs).

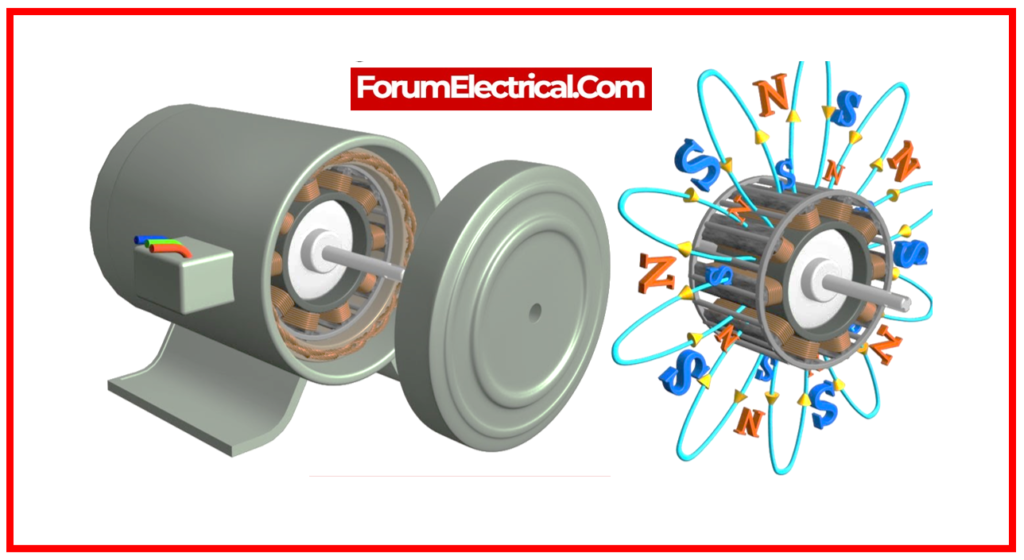

10. What are the primary parts of a synchronous motor?

A synchronous motor is made up of a stator, a rotor, an excitation system, and, in some conditions, a damper winding or a starting mechanism.

11. How does the synchronous motor’s excitation system work?

The excitation system generates a magnetic field by supplying direct current to rotor windings.

This field synchronizes with the rotating magnetic field of the stator, allowing motor to run at a synchronous speed.

12. Will synchronous motors run in the absence of an excitation system?

Synchronous motors, on the other end, rely on the excitation system to provide the magnetic field required for synchronism with stator field.

13. What are the various types of synchronous motor excitation systems?

There are two types:

- DC excitation systems – which use DC power to power the rotor, and

- Permanent magnet excitation systems – which use permanent magnets in the rotor to generate the magnetic field.

14. How is the power factor of synchronous motors controlled?

By adjusting the excitation current, synchronous motors can modify their power factor.

The power factor of the motor can be improved or corrected by altering the excitation.

15. What is the function of the damper winding in synchronous motors?

The damper winding assists the motor in starting by allowing for some early slip prior to attaining synchronous speed.

It also assists in the motor’s stability amid unexpected load fluctuations.

16. Will synchronous motors be employed in low-speed applications demanding high torque?

Synchronous motors normally function at synchronous rates and may not be the best solution for applications demanding high torque at low speeds unless additional gearing (or) modifications are used.

17. How are synchronous motors operated to regulate their speed?

In synchronous motors, speed regulation frequently involves managing the excitation (or) modifying frequency of power supply via variable frequency drives (VFDs).

18. What are the primary distinctions between synchronous reluctance & traditional synchronous motors?

Synchronous reluctance motors utilize the reluctance torque principle & feature a simplified rotor shape without windings or magnets. When compared to typical synchronous motors, they have the potential for improved efficiency and simpler construction.

19. May synchronous motors generate power when operated mechanically?

Because of its capacity to maintain synchronism with the power source, synchronous motors are functioning above synchronous speed can operate as generators, transforming the mechanical energy into the electrical energy.

20. How is the synchronous speed of synchronous motor calculated?

The RPM formula for synchronous speed is

Synchronous Motor Speed (RPM) = (120 X Frequency) / Number of Poles

Synchronous Motor Speed (RPM) = (120 X f)/P

21. How can you figure out how many poles a synchronous motor has?

The number of poles in synchronous motor is governed by the motor’s design and construction. It is a fixed feature that the manufacturer specifies.

22. What are the usual applications that benefit from synchronous motors’ high efficiency?

In applications requiring consistent speed and excellent efficiency, such as

- Industrial pumps,

- Compressors, fans, and

- Certain types of industrial machinery,

- Synchronous motors

are chosen.

23. What does the load angle impact synchronous motor operation?

The load angle is the angular difference between the magnetic fields of the stator and the rotor.

Proper load angle adjustment is critical for the motor’s efficiency and synchronism.

24. Can synchronous motors work in both driving and generating modes at the same time?

Synchronous motors, known as synchronous condensers, can function in driving mode while also generating electrical power to grid as generators in specific conditions.

25. What steps are done to reduce hunting (or) instability in synchronous motors?

To minimize hunting or instability in synchronous motors, several control systems and stabilizing technologies, such as

- Automated Voltage Regulators (AVRs) &

- Power System Stabilizers (PSSs),

are employed.

26. How does a synchronous motor’s excitation control system affect its efficiency and performance?

Optimizing excitation control system effects the efficiency, stability, and reaction to varying loads of the motor, as well as its power factor.

27. What are the most important factors to consider when acquiring a synchronous motor for a certain application?

The

- Required speed,

- Torque characteristics,

- Power factor requirements,

- Efficiency, and

- Capacity to control the motor’s operation

are all important considerations for choosing the right synchronous motor.

28. How is the power factor of synchronous motor measured, and why is it important?

Power analyzers (or) meters can be used to measure the power factor of a synchronous motor. It is a vital characteristic that indicates how efficient the motor is at converting electrical power into practical work.

29. Can synchronous motors coexist with other synchronous motors (or) power sources?

When synced to the same frequency and phase, synchronous motors can work in parallel with the other synchronous motors (or) power sources.

30. What are the fundamental problems in sustaining synchronous motor synchronism?

Maintaining synchronism entails dealing with difficulties like as load variations, transient situations, and effective regulation of the excitation system to avoid synchronism loss.

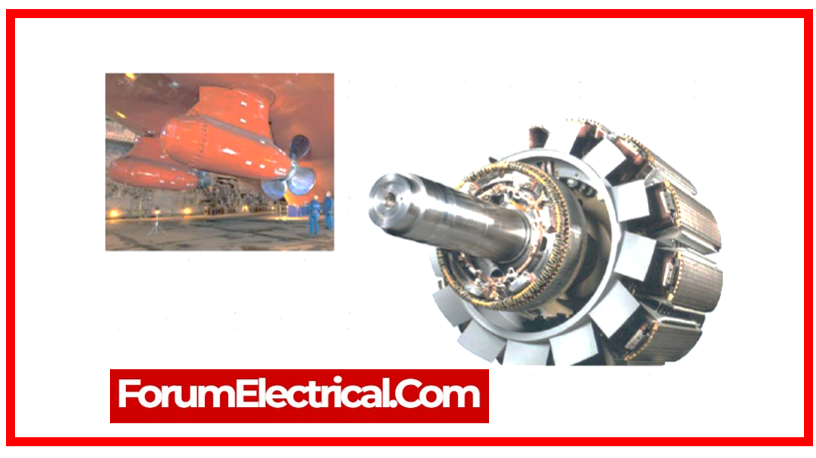

31. How does the rotor’s design and material choices affect the performance of the synchronous motor?

The inertia, ability to endure mechanical loads, and efficiency of a motor are all affected by the rotor design & material. High magnetic permeability materials are frequently employed to improve performance.

32. What are the benefits of synchronous motors with permanent magnet rotors?

Permanent magnet rotors outperform traditional rotor designs in terms of efficiency, power density, & potentially lower losses, resulting in improved motor performance.

33. How is the starting mechanism of a synchronous motor different from that of an induction motor?

In comparison to induction motors, which self-start, synchronous motors often require external help such as damper windings, starting motors, (or) extra devices to get them to synchronous speed before linking to the power source.

34. What are the properties of a synchronous motor’s torque-speed curve?

A synchronous motor’s torque-speed curve is relatively flat at the synchronous speed & rapidly declines while operating below synchronous speed.

It has a strong torque at the rated speed, making it perfect for constant-speed applications.

35. Can synchronous motors be run on a single-phase power supply?

While asynchronous motors can operate on single-phase power, synchronous motors need three-phase power due to the need for synchronism with a spinning magnetic field.

36. How are synchronous motor cooling systems designed to maintain optimum operating temperatures?

Cooling systems, such as air (or) liquid cooling, are installed in synchronous motors to remove the heat generated during the operation, guaranteeing ideal temperature & preventing overheating.

37. What are the various types of synchronous motor rotor constructions?

Synchronous motors can have a variety of rotor shapes, such as

- Cylindrical rotors,

- Salient pole rotors, or

- Interior permanent magnet (IPM) rotors,

each with their own set of performance characteristics.

38. How is the magnetic field of a synchronous motor adjusted to provide stability and control?

To maintain stability and control, the excitation system, which consists of field windings (or) permanent magnets, is controlled by regulating the excitation current (or) magnetic field strength.

39. Can synchronous motors be used in tough situations with high levels of vibration (or) extreme temperatures?

Synchronous motors can be built to resist extreme conditions by combining robust construction, insulation, & environmental protection techniques.

40. What function does the phase sequence perform in synchronous motor operation?

The correct phase sequence is essential for synchronizing numerous motors (or) connecting them to a power supply that ensures they rotate in the desired direction without harming their performance.

41. How does altering load conditions impact the efficiency of a synchronous motor?

Synchronous motors perform best under steady loads, but their efficiency may suffer when subjected to variable (or) fluctuating loads.

42. Are synchronous motors suitable for applications that require high precision and consistent speed control?

Yes, in applications requiring accurate speed control and consistent rotational speed, which include precision machining (or) motion control systems, synchronous motors are favored.

43. How do synchronous motors vary from Permanent Magnet Synchronous Motors (PMSM)?

While both work at synchronous speeds, PMSMs feature permanent magnets integrated in the rotor, which provides more efficiency and torque density than conventional synchronous motors.

44. How is the torque generated by a synchronous motor calculated?

The formula for calculating torque in a synchronous motor is as follows:

Torque = Power (watts) / (2 x П x Speed)

45. What are the consequences of under-excitation and over-excitation in the synchronous motors?

Under-excitation can result in reduced power production and overheating, whereas over-excitation can result in excessive reactive power & resulting motor instability.

46. Are synchronous motors capable of operating at speeds greater than their synchronous speed?

Synchronous motors are designed to run at synchronous speeds, and exceeding that speed may necessitate modifications (or) additional equipment.

47. Why does the phase angle affect synchronous motor performance?

The phase angle among the magnetic fields of the stator and rotor governs the motor’s torque production and influences its operating parameters.

48. What variables influence the use of synchronous motors over induction motors for particular applications?

The selection between synchronous & induction motors is influenced by factors such as needed speed, torque characteristics, control needs, and efficiency considerations.

49. Why are synchronous motors protected during operation against defects or abnormalities?

To prevent damage during faults, synchronous motors incorporate preventative measures such as

- Overcurrent protection,

- Temperature monitoring,

- Vibration analysis, and

- Automatic shutdown systems.

50. May synchronous motors be utilized for regenerative braking?

Synchronous motors can be used in regenerative braking systems, which transform the mechanical energy into the electrical energy while slowing or stopping machinery.