- What is a Control System?

- Characteristics of Control Systems

- Requirements for an Effective Control System

- Types of Control Systems

- Types of Control Systems based on Feedback Path

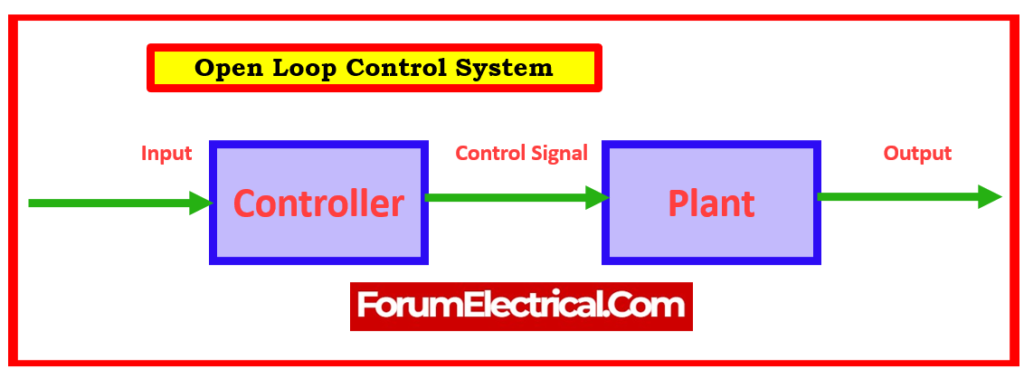

- Open-Loop Control Systems

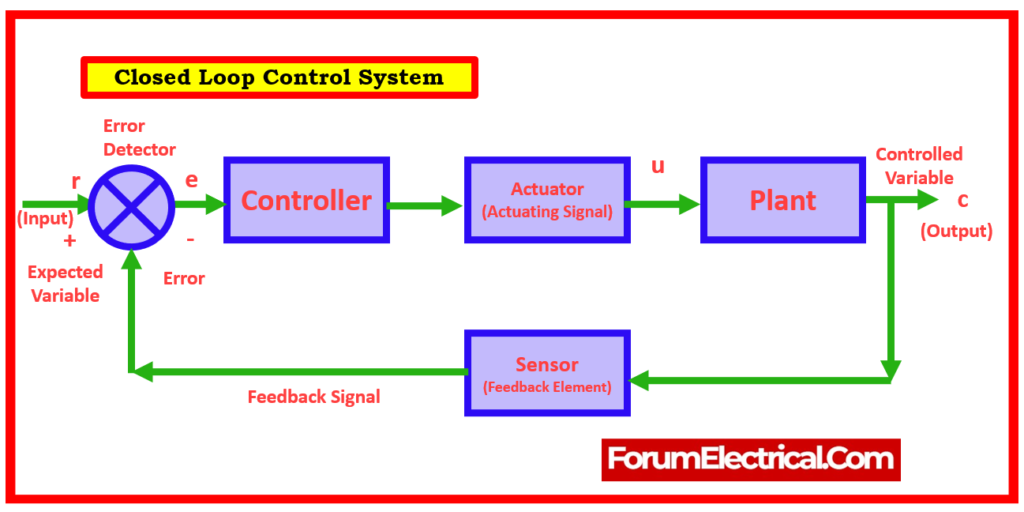

- Closed-Loop Control Systems

- Types of Control Systems based on Parameters

- Continuous Time Control Systems

- Discrete-Time Control Systems

- Types of Control Systems based on Input & Output

- SISO Control Systems

- MIMO Control Systems

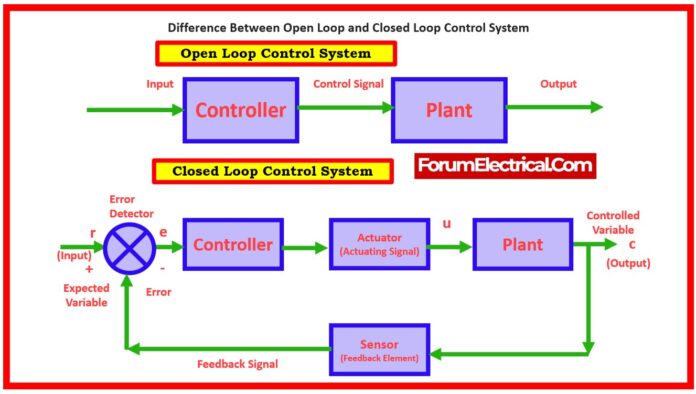

- Difference between Open-Loop and Closed-Loop Control System

- Open Loop vs Closed Loop Control Systems

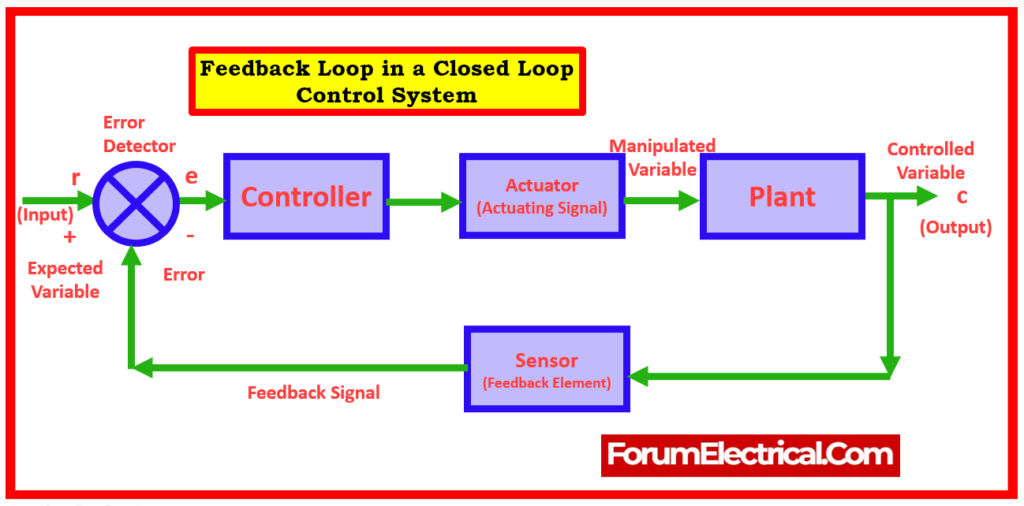

- Feedback Loop in Closed Loop Control System

What is a Control System?

A control system is a collection of devices that controls, directs, commands, (or) regulates the operation of other devices (or) systems in order to achieve a specific outcome.

A control system does this using control loops, that are processes that keep a process variable at a specific set point.

In other words, a control system can be defined as a system that regulates other systems.

As human society progresses, the desire for automation develops.

Automation necessitates control over a network of interconnected devices.

Control systems have played an increasingly important part in the evolution & development of modern technology & society.

Almost every element of our daily lives is influenced in some way by a control system.

Control systems in your daily life include

- An air conditioner,

- A refrigerator,

- A bathroom toilet tank,

- An automated iron, and

- A variety of automotive operations such as cruise control.

Control systems can be found in industrial contexts such as

- Product quality control,

- Weapons systems,

- Transportation systems,

- Power systems,

- Space technology,

- Robots, & many more applications.

Control theory ideas apply to both the technical and non-engineering fields.

Characteristics of Control Systems

The essential characteristic of a control system is that the system’s input and output have a clear mathematical relationship.

A linear control system is defined as one in which the connection between the system’s input and output may be expressed by linear proportionality.

A non-linear control system is one in which the connection between input & output cannot be easily represented by a single linear proportionality and instead is determined by some non-linear relation.

Requirements for an Effective Control System

Accuracy: Accuracy is the instrument’s measurement tolerance, which determines the limits of errors generated when the instrument is utilized under typical working conditions.

The use of feedback features can help enhance accuracy. To boost the accuracy of the control system, an error detector must be included.

Sensitivity: The settings of a control system are constantly changing due to changes in the external environment, internal disturbances, or other parameters.

This change may be quantified in regards to sensitivity. The control system must be indifferent to such factors and only respond to input signals.

Noise: Noise is defined as an undesirable input signal. An effective control system must be able minimize the noise effect and improve performance.

Stability: Stability is a key feature of the control system. The output of a bounded input signal must be bounded, & if the input is 0, the output must also be 0, indicating that the control system is stable.

Bandwidth: A control system’s bandwidth is determined by its operational frequency range. A good control system’s frequency response should have the widest bandwidth available.

Speed: The time it takes for the control system to produce a stable output. A reliable control system operates at fast speeds. The transitory period associated with such a system is relatively short.

Oscillation: A modest number of oscillations (or) continuous oscillations of output suggest that the system is stable.

Types of Control Systems

There are several types of control systems, however they are all designed to control outputs.

Control systems include those that

- Control location,

- Velocity,

- Acceleration,

- Temperature,

- Pressure,

- Voltage, and

- Current, among other things.

Types of Control Systems based on Feedback Path

Control systems classified into two types. They are as follows:

- Open-loop control systems.

- Closed-loop control systems

Open-Loop Control Systems

Open-loop control systems have control actions that are completely independent of the system’s output. A manual control system is essentially an open-loop system.

An open loop control system does not feed the output signal back to the system’s input. An open loop control system is also known as a non-feedback control system.

In open loop control systems, the output is not fed back into the input. As a result, the control action acts independently of the desired outcome.

When an input is fed to a controller, it generates an actuating or controlling signal. This signal is sent as an input to the plant or process that needs to be regulated. So, the plant provides a controlled output.

Example of Open-Loop Control Systems:

- The traffic light control system, which is a prime example of an open loop control system.

- In, electric hand drier, hot air comes out for so long that you keep your hand beneath the machine, regardless of drying.

- Automatic washing machine runs at the pre-set time whether washing is done or not.

- Bread toaster runs on time regardless of toasting status.

- Automatic tea/coffee makers work for pre-set times.

- This timer-based clothes dryer dries wet garments for a pre-adjusted time, regardless of how much they dry.

- Lamps illuminate when the light switch is on regardless of need.

- Stereo system volume is manually adjusted regardless of output volume.

Advantages of Open Loop Control Systems

- Simple in build and design.

- Economical.

- Simple to maintain.

- Generally stable.

- Convenient to utilize, as output is tough to quantify.

Disadvantages of Open Loop Control Systems

- They are not accurate.

- They are not reliable.

- Any variation in output could not be adjusted automatically.

Closed-Loop Control Systems

A closed-loop control system is one in which the output affects the input quantity in such a way that the input quantity adjusts itself in response to the output created.

Providing feedback can transform an open-loop control system to a closed-loop control system. This feedback automatically adjusts the output in response to external disturbance.

In this manner, a closed loop control system is known as an automatic control system.

In this system, the control action is determined by the intended output signal.

Example of Closed-Loop Control Systems:

- Automatic electric irons control heating components by output temperature.

- The system output voltage controls the servo voltage stabilizer.

- Input water is governed by reservoir water level.

- Radar launched & auto tracked missile are monitoring the target and missile position controls its direction.

- Air conditioners work based on room temperature.

- Car cooling system works based on temperature.

Advantages of Closed Loop Control Systems

- Closed loop control systems remain significantly accurate, even in the face of nonlinearity.

- Highly accurate because the very existence of a feedback signal corrects any errors that may occur.

- The bandwidth range quite large.

- Enables automation.

- The system’s sensitivity can be reduced to increase its stability.

- This mechanism is less sensitive to noise.

Disadvantages of Closed Loop Control System

- They cost more.

- They are difficult to design.

- Additional maintenance was required.

- Feedback produces an oscillating reaction.

- Feedback reduces overall gain.

- Stability is the most significant problem, therefore designing a stable closed loop system requires greater consideration.

Types of Control Systems based on Parameters

Following are some of the types in which we are able to categorize the control systems based on parameters:

- Continuous Time Control Systems and

- Discrete-Time Control Systems

Continuous Time Control Systems

Continuous time control systems are characterized by the certainty that all of the signals are continuous in time.

Discrete-Time Control Systems

There are one (or) more discrete time signals that are present in control systems that operate in discrete time.

Types of Control Systems based on Input & Output

Depending on how many inputs and outputs are provided, control systems can be classified as

- SISO Control Systems and

- MIMO Control Systems.

SISO Control Systems

Control systems that are referred to as SISO (Single Input & Single Output) feature a single input and a single output.

MIMO Control Systems

More than one input & more than one output are characteristics of MIMO control systems, which stands for multiple inputs and multiple outputs.

Difference between Open-Loop and Closed-Loop Control System

Open Loop vs Closed Loop Control Systems

| Open-Loop Control System | Closed-Loop Control System |

| In Open loop control system, the regulated action is separate from the output. | In Closed-loop control system, the output is primarily determined by the regulated act of the system. |

| This is also known as a non-feedback control system. | This is also known as a feedback control system. |

| This system consists of a controlled process & a controller. | This type of system consists of controlled process, controller, an amplifier, and feedback. |

| This system’s construction is simple. | This system’s construction is complex. |

| The consistency is not reliable. | It is reliable in its consistency. |

| The calibration is the primary factor influencing this system’s accuracy. | As a result of feedback, these are accurate. |

| The stability of open loop control systems is stable | The stability of closed loop control systems is less stable |

| In this particular system, optimization is not a feasible option. | Within the structure of this system, optimization is possible. |

| It responds quickly. | Response time is slow. |

| This system’s disturbance will be affected. | This system will not be affected by the disturbance. |

| These systems are not linear. | These are linear systems. |

| This system’s disturbance will be affected. | This system will not be affected by the disturbance. |

| Examples of this control system include automatic washing machines, traffic lights, television remotes, immersion rods, and more. | This type of control system includes air conditioning, temperature, pressure, and speed control systems, toasters, and refrigerators. |

Feedback Loop in Closed Loop Control System

When developing a control system, feedback is an important and useful tool.

The feedback loop is a tool that considers the system output and allows the system to alter its performance to achieve the intended result.

The output of any control system is altered by changes in environmental factors or other types of disturbances.

So, one signal is obtained from the output & fed back into the input.

This signal is compared to a reference input, and an error signal is produced. This erroneous signal is fed into the controller, & the output is corrected.

Such a mechanism is known as a feedback system.

Positive Feedback System

A positive feedback system is defined as one in which the feedback signal is positive.

In a positive feedback system, error signal is the sum of the reference input signal and the feedback signal.

Negative Feedback System

A negative feedback system is defined as one in which the feedback signal is negative.

The error signal in a negative feedback system is calculated as the difference between the reference input signal & the feedback signal.

Effect of Feedback in the Control System

The following labels are applicable:

R – input signal

E – Error signal

G – forward path gain

H – Feedback

C – Output signal.

B – Feedback signal

Feedback affects a control system in the following ways:

- The error between system input & output has been decreased.

- System gain is lowered by a factor of 1/(1±GH).

- Improved insensitivity (less reactive to change).

- Stability has improved.