What is meant by the term “Electrical Panel Board Inspection “?

This can include examining the state of the panel, inspecting the wiring & connections, testing for correct grounding & bonding, verifying the proper functioning of safety devices, and assuring compliance with industry rules and regulations.

Typically, the electrical panel inspection will consist of a list of functions, such as the following, that are required to be inspected:

- The overall condition of the electrical panel (including any rust, corrosion, or damage).

- The panel’s labeling, including whether or not the labels are accurate and easily readable.

- Wiring and connections (including factors such as snugness, appropriate size, and adequate wire terminations)

- Protection against overcurrent, such as circuit breakers and fuses.

- Bonding and grounding (for example, the panel should be properly grounded, and there should be a grounding conductor present)

- Protective equipment such as GFCI outlets and ARC-fault circuit breakers

- Maintaining compliance with relevant industry codes & regulations

The following is a list of some of the more general stages involved in utilizing an electrical panel inspection:

- Identify the electrical panel: This is typically a metal box that houses the main circuit breaker (or) fuse, as well as individual circuit breakers or fuses.

- Turn off the electricity: It is critical to cut off the power to the electrical panel before doing any examination or maintenance on it. This is normally accomplished by turning off the main circuit breaker (or) fuse.

- Examine the panel cover: Check that the lid is securely fastened and verify that there is no corrosion, rust, or overheating.

- Examine the primary circuit breaker (or) fuse: Check to see if it is properly labeled & in good condition.

- Examine each circuit breaker or fuse individually: Check to see if they are correctly labeled & in good condition. Examine the circuit for any tripped breakers (or) blown fuses.

- Check the wiring: Check the wiring to ensure that it is correctly connected and verify that there are no loose connections (or) indications of damage. Examine the grounding and look for any frayed (or) exposed wires.

- Examine for GFCI & Arc Fault Protection: They must be present and operational.

- Keep track of any concerns or problems: Make a note of any difficulties or problems identified throughout the test, and document any suggested fixes or changes.

Visual Inspection

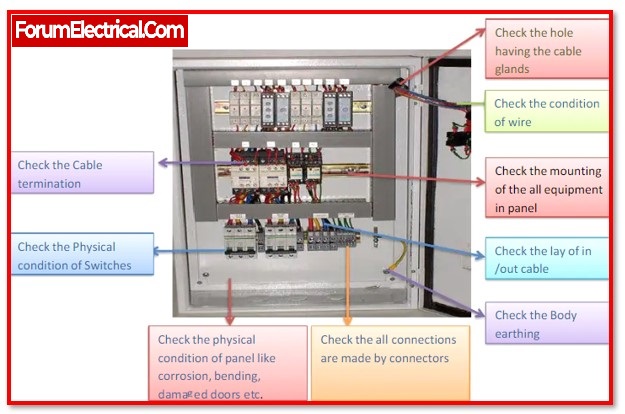

1. Verify whether the panel board installation on the equipment is stable.

2. Check whether the in- and out-lay of the cable is correct.

3. Examine the panel’s physical state for hazards such as bending, corrosion, and damaged doors.

4. Examine the electrical cable’s physical state for any cuts, burn marks, or exposed live parts.

Changes in Cable Color

- Brown/Red: Caused by Overcurrent

- Black: Caused by Short Circuit

5. Check that the cable termination has a ferrule number and a ring or “u ” terminal.

6. Check that the cable’s size matches the drawing.

7. Check that the switches, contactors, timers, and fuses are in good physical condition.

8. Checks that the fuses, contactors, and switches in the panel are appropriate for the load’s current rating.

9. Check whether or not all of the equipment mountings in the panel are fixed.

10. Verify that the cable termination and bus bar connection are tight.

11. Check that every cable joint is created using connectors.

12. Check whether the panel’s inside is correctly earthed.

According to AEWR, the body of the panel and neutral must be earthed by a minimum of two earth electrodes, which are typically made of steel-cored copper rods with a diameter of 15 mm that are driven to a minimum depth of 3 m.

13. Examine the opening where the gland-holding cable is located.

14. Press the panel’s emergency switch to check it. If the machinery stops, it is functioning correctly.

15. Use the continuity and parameter checking tests to verify that switches are operating properly.

Incoming Supply

Parameter Check

Voltage

The voltage is measured with an instrument known as a multimeter. Connect the two multimeter leads across the incoming connection where want to measure the rouge heating up, making sure the multimeter knob is set to AC voltage. Check the voltage value displayed.

- Voltage normal value for 3 phase-440V

- Voltage normal value for 1 phase-230V

Nominal supply voltage with a variation of +20% -% is permissible.

Current

A device known as a clamp meter is used to measure the amount of current that is flowing through the electrical panel.

For the measurement of current, place the clamp of the tester through one of the phases of the incomer power cable, and then move the arrow on the knob to the current (A) position, as shown.

This will allow us to take the measurement. The value of the current needs to be approximately equivalent to the value of the load’s rated current. If it appears to be higher than typical, this indicates that there is a problem with the load itself.

Frequency

The term “Multimeter” refers to the instrument that is used in the process of measuring frequency.

Connect the two leads of the multimeter so that they are positioned across the incoming terminal that has to have its frequency measured. Check to see that the arrow on the multimeter’s knob is pointing toward the frequency position. Verify that the value of frequency that was displayed is correct.

The frequency at its normal value is 50 Hz+/- (or) 60Hz.

0.1% of the supply frequency, or +/- 0.05 Hz, shall be considered acceptable range for frequency variation.(In accordance ESMA Regulation 2007).

Earth Resistance

The megger tester is used to determine the value of the earth’s resistance. The megger tester has three terminals, and they are labeled C, P, and E. Install two auxiliary electrodes, or supplementary earth rods, at a distance of five meters from the main electrode, which will be used to assess earth resistance. The primary electrode will be the earth rod that is being tested.

Connect the terminal labeled “E” to the main electrode, and the terminals labeled “P” and “C” to the remaining auxiliary electrodes, respectively.

Examine the value that is displayed.

In accordance with ESMA regulation, the earth resistance value must be no more than 10 Ohms.

Visual inspection of the Switches and Contactors

Establish the continuity setting on the multimeter

Check to determine if the multimeter makes a “beep” sound when both leads are touched together.

One lead should be connected to the switch’s bottom terminal, and the other should be connected to the switch’s top terminal.

The switch is in good health despite the following condition.

- When the switch is close or the switch is on, a “beep” sound will occur.

- When the switch is off or open, and there is no sound.

Thermography

Temperature guns are utilized in the process of measuring the temperature of the electrical panel.

The maximum temperature that can be reached is 70° Celsius.

What is the purpose of an Electrical Panel Inspection?

Electricians and electrical maintenance professionals implement the electrical panel inspection to ensure that electrical panels are safe, functioning, and in compliance with industry rules.

This helps to find and address faults before they become significant problems, extends the life of the equipment, and ensures the safety of that structure.

Some of the reasons why an electrical panel may need to be inspected include:

- Regular inspections can assist in identifying potential problems prior to cause a power failure. This may assist with prevent power outages, equipment damage, & other problems that can be inconvenient and dangerous.

- Electrical panels & the systems they regulate can pose major safety risks, including electrical shock, fires, & explosions. An inspection can assist in identifying potential hazards and mitigating them.

- Codes and regulations demand that electrical panels be inspected on a regular basis to verify that they fulfill safety standards. An inspection may assure that an electrical panel is up to code and operates in accordance with the latest NEC and local standards.

- An older electrical panel cannot have the capacity (or) capability to manage the demands of modern appliances and usage; evaluating it can assist identify such problems and determine whether an upgrade is required.