- Motor Starter

- What is a Soft Starter?

- Soft Starter Diagram

- Working Principle of Soft Starter

- Advantages of Soft Starter

- Disadvantages of a Soft Starter

- Applications of Soft Starters

- Soft starter Selection Factors

- Characteristics of Soft Starters

- Types of Soft Starters

- How are voltage controls ensured by soft starters?

Various machine types are used in industries. One of the most popular three-phase AC machines, induction motors account for roughly 70% of all industrial motors. They are the most ideal option for any industry because to their strong structure and great efficiency. However, in order to operate properly, avoid any potential harm to the motor, and also lengthen their useful lives, they do need the protection measures and equipment necessary for their safe operation. A motor starter is the most important part of machinery utilized with three phase induction motors.

Motor Starter

An electrical device called a motor starter is used to start and stop electrical motors in a secure manner. Additionally, it provides low voltage and overcurrent protection.

Since induction motors are widely utilized in a variety of industrial applications, motor starters are required to start and stop them securely. At startup, induction motors consume a significant amount of current. It results from the motor’s windings’ low standing impedance.

It’s essential induction motor safety. Motor rotor impedance is low at rest position. The induction motor slip determines the rotor impedance. The rotor impedance of an induction motor fluctuates due to its slip. It’s inversely proportional to motor slip.

The rotor impedance is lowest when the induction motor is at rest since its slip is 1. This low impedance, called inrush current, draws a lot of current in stator winding when the motor is connected to power. The stator’s alternating current creates a rotating magnetic field (RMF) that induces current in rotor windings.

The motor’s high inrush current is (5-8) times its full load rated current. Induction motors cannot handle such current because it damages or burns the windings, lowering performance and lifespan. High currents can also drop line voltage, which is problematic for other appliances.

Manufacturers employ motor starters to lower inrush current for a limited period to avoid such excessive current. Normal power supply resumes when the motor speeds up. Low voltage & overcurrent protection are also provided.

Such motor starters are typically utilized for high-power motors. Small motors under 1Hp don’t need motor starters because of their high impedance. DOL starters overcurrent protection is needed.

The rotor current generates a magnetic field to negate its cause and rotate in the direction of RMF. Thus, the rotor experiences torque and as its speed increases, the motor slip reduces (i.e., the rotor RMF speed approach stator RMF speed). The motor draws normal rated current when the slip is lowered because the rotor’s resistance increases.

What is a Soft Starter?

A form of motor starter called a soft starter is used to lower the load and starting torque on the motor. By reducing

- Mechanical &

- Electrodynamic stress on motors,

this feature helps to increase their lifespan.

Soft starters make sure that the voltage increases gradually when the motor starts. This enables the motor to gradually pick up speed while accelerating gently. This system controls the rapid voltage supply while guarding the motor against mechanical harm.

The supply voltage is used to regulate the motor starting. This is so because an induction motor’s current, which is directly proportional to its torque, depends on supply voltage.

Maximum starting torque can be produced by using full voltage to start a typical motor starter, but doing so runs with the possibility of mechanical harm to the motor.

A soft starter reduces starting torque as a result and gradually increases it in a secure manner till it reaches the rated speed. The soft starter returns the full voltage to the motor once it has reached its rated speed.

When the motor stops, the provided voltage steadily drops, causing the motor to slow down smoothly. The motor’s input power source is shut off as the speed gets close to zero.

- Mechanical,

- Electrical, or

- Combination of mechanical & electrical components

can generate up soft starts. Similar to other forms of torque limiters, mechanical soft starts include clutches and other couplings that transmit torque through fluid, magnetic forces, (or) steel shot.

Any control system that decreases torque by lowering the voltage (or) current input, (or) a device that rapidly changes how the motor is connected in the electric circuit, can be an electrical soft starter.

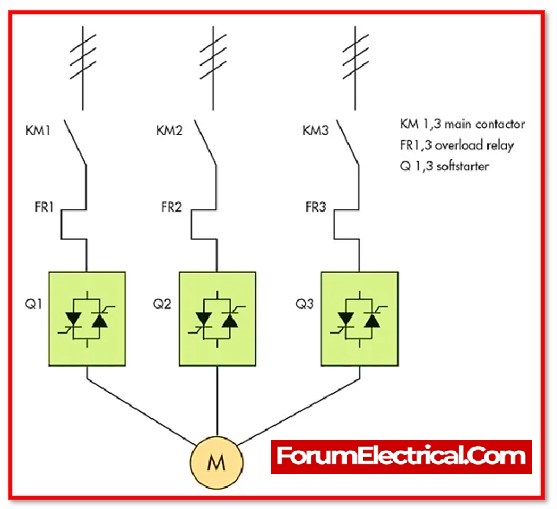

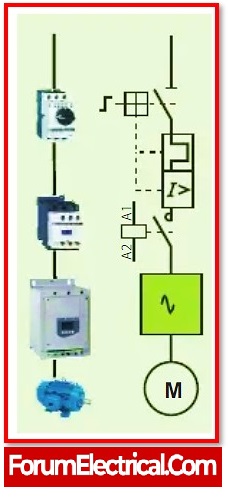

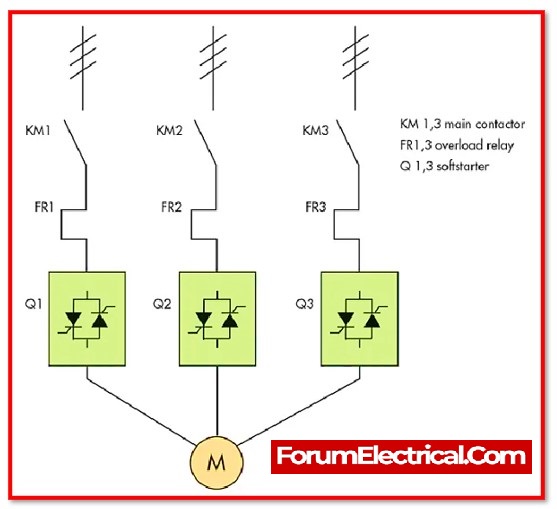

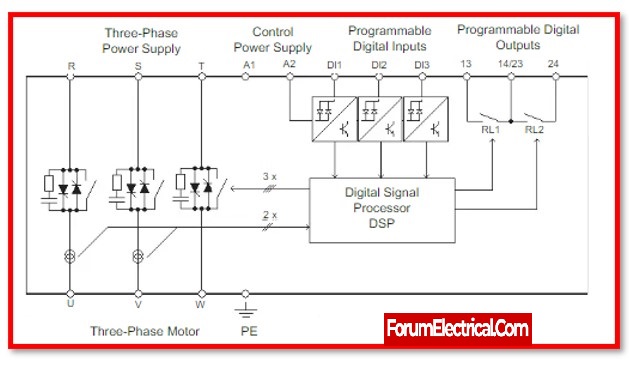

Soft Starter Diagram

Two SCRs are coupled in an anti-parallel manner along each phase of an induction motor with three phases, making a total of six SCRs in the motor. A separate logic circuitry, such as a PID controller (or) a microprocessor, is used to regulate these SCRs. Using a rectifier circuit, as indicated in the diagram, the logic circuitry is supplied with power .

Other protection mechanisms, such as the circuit breaker (or) fuse, magnetic contactor for isolation, and an OLR (Overload relay) for overcurrent prevention are utilized in addition to the power switches and logic circuits.

When the motor reaches its full rated speed, a bypass switch is also employed to restore the entire voltage across the motor.

Working Principle of Soft Starter

A motor soft starter regulates the voltage that passes through the motor’s circuits. This is accomplished by restricting motor torque and allowing the soft starter to gradually reduce voltage to allow for a steady flow of current.

To attain specific levels of control, certain soft starter models employ solid-state electronics. Such devices are yet another technique for the soft starter to manage the level of electrical current flowing into the motor.

When the motor starts, most electrical soft starters use a sequence of SCR (or) thyristors to reduce the voltage to a more controllable level. These SCRs possess an ON state that allows current to flow and an OFF state that controls and limits electrical current. When the machine is turned on, the SCRs are triggered. Furthermore, they limit the voltage & rest after the machine reaches full power. This method significantly minimizes the heat generated by the motor and the overall mechanical strain.

Mechanical soft starts use clutches and other couplings to control torque in the motor utilizing fluids, steel shot, (or) magnetic forces. As already stated, this minimizes the amount of electricity that can flow through the motor, enabling it to start up more softly & easily.

Advantages of Soft Starter

1). Smooth Start

In contrast to typical motor starters, it provides a very progressive increase in voltage and speed, creating an exceptionally smooth startup. There is absolutely no mechanical stress or jerks that could harm the motor.

2). Control for acceleration and deceleration

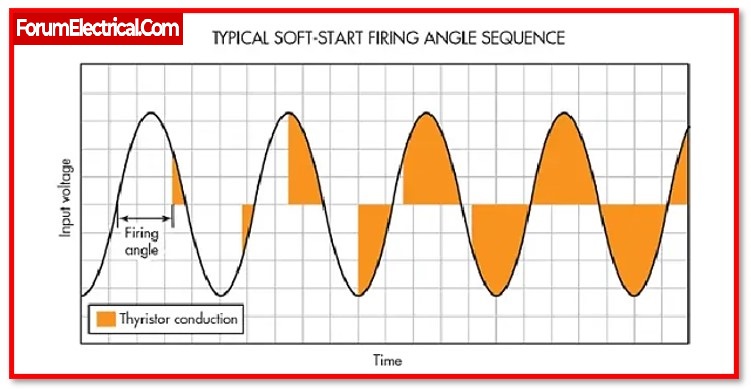

It enables completely adjustable motor acceleration and deceleration. The acceleration during motor initiation and deceleration during motor stopping can be controlled by changing the firing angle slowly (or) quickly. When starting acceleration requires to be modified, this is used.

3). No Power Surges

A significant inrush current starts flowing into the motor because the traditional motor starter permits full voltage across the motor, which results in a power surge in the circuit. The soft starter controls this current to avoid power surges.

4). Several Startups

In some applications, the motor must start and stop more than once in a short space of time. Such a motor will overheat due to a high starting current if utilized with a standard starter. However, soft starters significantly boost a motor’s number of starts in a given period of time.

5). Reduced Overheating

The overheating of the motor is a very dangerous issue. It happens as a result of the high starting winding current. A minimal amount of the starting current is permitted by the soft starter, preventing the motor from overheating.

6). Longer Life Expectancy

The motor’s lifespan is increased by the soft starting when compared to a traditional starter. It results from the motor’s smooth running and lack of mechanical or electrical stress.

7). Reduced Maintenance

Induction motors require less maintenance than conventional motor starters because they operate smoothly and are less likely to develop mechanical problems.

8). Efficiency

A typical motor starter supplies the motor with full voltage (extremely high inrush current). A soft starter greatly minimizes it and permits a steady increase in energy usage. Also, very low voltage levels are used to regulate the power switches. It raises the motor’s overall effectiveness.

9). Small and Compact Size

The soft starter having a very tiny size and a very compact design. It is much smaller than other motor starters.

10). Low Price

This certainly costs less than other starters like VFD.

Disadvantages of a Soft Starter

1).No Speed Regulation

Only input voltage supply, from 0 V to line voltage with a predetermined line frequency, is controllable by the soft starter. As the frequency is constant, the only factor affecting the motor’s speed is the load it is linked. Depending on the conditions, the supply frequency is adjusted below (or) above the line frequency to control the speed of the induction motor. Only VFD’s (Variable Frequency Drives)have access to such a feature.

2). Dissipation of Heat

The soft starter’s semiconductor switches release some energy as heat during operation. As a result, heat sinks are also necessary for cooling power switches.

3). Reduced Starting Torque

Applications of Soft Starters

1). Water (or) Liquid Pump applications

Power surges are always a serious concern in pump applications. In these conditions, soft starts assist in gradually raising the pressure and lowering the associated hazards.

2). Conveyor Belts

These industrial systems, which transport huge loads, must be optimized utilizing a soft starting. The belt driving components may likely experience jerks, misalignment, needless stress, and more as a result of conveyor belts starting suddenly. These belts are protected while having a smooth starting & stopping operation because of soft starters.

3). Fans and similar systems

Industries often employ large fans that run continuously. However, in order to maintain smooth operation and allow them to run for longer periods of time, they do need starting protection, such as soft starters.

4). Motors using Belts & Pulleys

The motor that uses belts and pulleys to move the load cannot endure the sudden jerks. It is belted to the weight of the load. A soft starter enables a smooth start for certain motor applications.

Soft starter Selection Factors

The following factors must be considered while selecting a soft starter:

- Applications and their use

- Motor nominal power & current

- The application’s load factor

Finding the ideal balance between both voltage reduction & torque requirement is essential, as restricting the current too much would make it impossible to start the motor and inadequate restriction will make it pointless to use a soft starter.

Starts per period are also important. Using a soft starter generates heat, thus the motor can only be stopped and started so many times. If there are several starts and pauses each hour, the soft starter may need to be larger than the motor power.

- Bypass &

- Line contactors

are recommended.

A bypass contactor parallel to soft starter diverts electricity when the motor reaches operational speed. This decreases energy loss and soft starter lifespan.

For safe power disconnection, a line contactor is fitted serially to soft starter. Soft starters with incorporated bypass switches don’t need bypass contactors.

Characteristics of Soft Starters

- Changing the starting voltage for a set period of time.

- Starting voltage pulse for loads with strong starting torque.

- Reduce hydraulic shocks in the pumping systems by quickly reducing voltage to a variable level.

- Protection from phase failure, excess current, and undercurrent, among other hazards.

- Soft starters are the micro-processed devices used to protect and speed up (or slow down) 3-phase induction motors.

Types of Soft Starters

There are five distinct types of soft starters

1). Primary Resistor

In order to prevent current flow, a resistor is added during each phase of the current in this type. When the motor is started, the resistor blocks the flow of current, which lowers the voltage. The primary resistor starters have the advantage of two-point acceleration and are suitable for smooth starting.

2). Auto Transformers

One of the best methods for gentle starting a motor is with auto transformers. A transformer is used in place of the resistor of the primary resistor type, and the starter must tap the transformer to provide power to the motor. Compared to other soft starting types, they can provide the motor with a higher current.

3). Part Winding

This method divides the motor winding into multiple sets. The objective of the identical set is to carry out simultaneous operations.

A motor winding single set receives power. As soon as the motor reaches its top speed, the other winding sets receive power to resume normal operation. Reduced starting torques & currents are significant achievements.

4). Wye Delta

This necessitates that the three coil windings on the motor be connected.

5). Solid State

The most recent method integrates electronic components for machines. Here, the SCR, which is utilized to regulate the motor voltage while it accelerates, is important.

How are voltage controls ensured by soft starters?

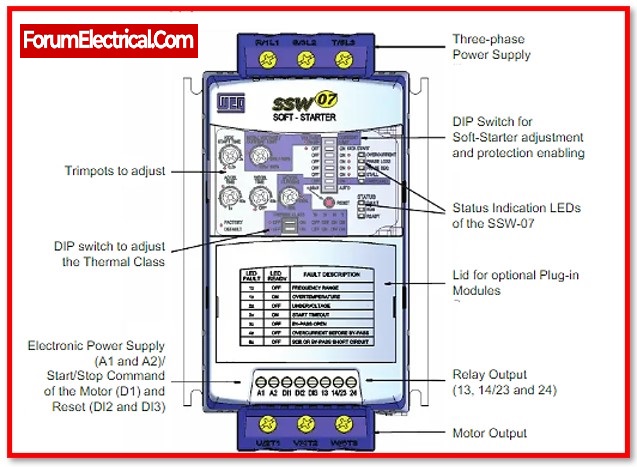

Basically, a motor soft starter consists of two parts:

1). Power circuit

The current that is delivered to the motor flows around this circuit. This is made up of a number of thyristors, as well as protections & current transformers.

2). Control circuit

Along with the user interface circuitry that can be adjusted for each application, this circuit is in charge of managing, observing, and protecting the parts of the power supplies circuit.

A group of thyristors open (ON) in response to a gate pulse (firing pulse), allowing current to flow and energizing the motor in the appropriate phase. How much current can flow and for how long depends on the angle of a each pulse.

It is feasible to produce an efficient voltage at the output that rises gradually & continuously until it approaches the nominal voltage of the network due to the thyristors’ capacity to manage the change of the firing angle.

By establishing specific parameters to restrict current flow, the user can control the firing pulse’s angle and the current flow’s duration through the control circuitry. Soft starters work like the following:

- Control the motors’ functionality, especially during the starting & stopping processes.

- Avoid high voltages and extreme heat on the motors and controls.